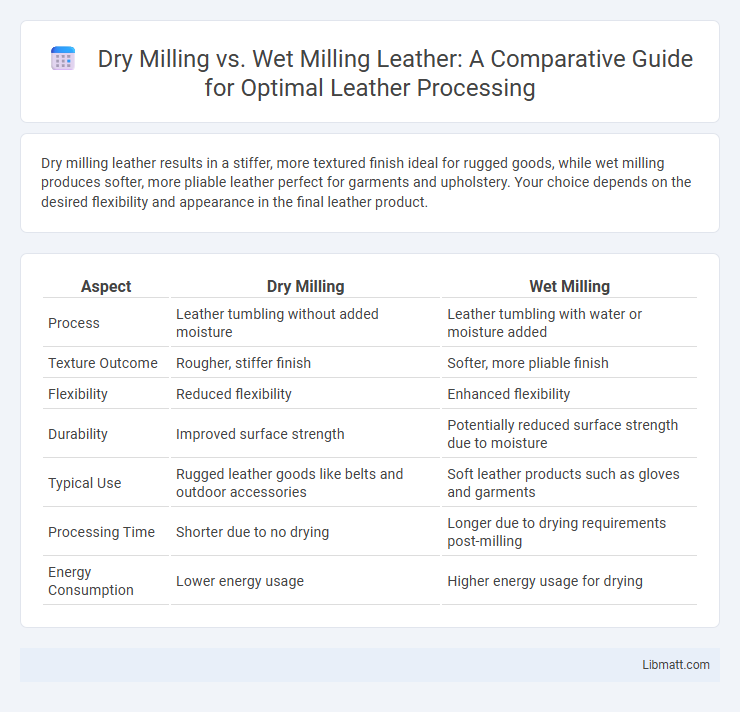

Dry milling leather results in a stiffer, more textured finish ideal for rugged goods, while wet milling produces softer, more pliable leather perfect for garments and upholstery. Your choice depends on the desired flexibility and appearance in the final leather product.

Table of Comparison

| Aspect | Dry Milling | Wet Milling |

|---|---|---|

| Process | Leather tumbling without added moisture | Leather tumbling with water or moisture added |

| Texture Outcome | Rougher, stiffer finish | Softer, more pliable finish |

| Flexibility | Reduced flexibility | Enhanced flexibility |

| Durability | Improved surface strength | Potentially reduced surface strength due to moisture |

| Typical Use | Rugged leather goods like belts and outdoor accessories | Soft leather products such as gloves and garments |

| Processing Time | Shorter due to no drying | Longer due to drying requirements post-milling |

| Energy Consumption | Lower energy usage | Higher energy usage for drying |

Introduction to Leather Milling Processes

Leather milling processes, including dry milling and wet milling, significantly influence the texture and softness of leather products. Dry milling tightens the leather fibers through controlled friction, enhancing durability and providing a firm finish, while wet milling involves soaking the leather to soften fibers, resulting in a more supple and flexible material. Understanding these processes helps you select the ideal milling method to achieve specific aesthetic and performance characteristics in leather goods.

What is Dry Milling in Leather Production?

Dry milling in leather production is a mechanical process that softens and enhances the texture of leather by tumbling it in a dry state, without the addition of water or moisture. This technique increases leather's suppleness, improves grain uniformity, and accelerates the aging of the hide for a more desirable finish. Dry milling is preferred for producing lightweight, smooth leather products with a consistent appearance across the surface.

What is Wet Milling in Leather Production?

Wet milling in leather production involves soaking leather hides in water or specialized solutions to soften the material, making it more pliable for shaping and molding processes. This technique enhances the leather's flexibility and texture, enabling craftsmen to create intricate designs and forms that would be difficult with dry leather. Wet milling is essential for producing high-quality leather goods that require detailed finishing and durability.

Key Differences: Dry Milling vs Wet Milling

Dry milling leather involves processing the hide in a non-moist environment, resulting in a firmer, stiffer finish ideal for structured products like handbags and belts. Wet milling, by contrast, softens the leather through moisture exposure and tumbling, producing a more pliable, supple texture suited for gloves and upholstery. The choice between dry and wet milling significantly affects the leather's flexibility, grain tightness, and final aesthetic.

Impact on Leather Texture and Finish

Dry milling leather creates a stiffer, more textured surface by allowing fibers to compact with minimal moisture, producing a matte finish ideal for structured goods. Wet milling softens the leather significantly as water opens the fibers, resulting in a smoother, more flexible texture with a glossier, polished look. Your choice between these processes directly affects the tactile feel and visual appeal of the final leather product.

Equipment Used in Dry and Wet Milling

Dry milling leather utilizes specialized tumblers or rotary drums that operate without added moisture, relying on friction and heat generated by mechanical action to soften and break down the fibers. Wet milling employs soaking vats or drums filled with water or a controlled solution, combined with mechanical agitation to swell and soften the leather, enhancing pliability. Equipment for wet milling often includes temperature controls and drainage systems to maintain optimal hydration levels, whereas dry milling machines prioritize airflow and heat dispersion to prevent overheating.

Advantages and Disadvantages of Dry Milling

Dry milling leather offers advantages such as reduced water usage and faster processing times, leading to lower production costs and environmental impact. However, it may result in stiffer textures and increased wear on milling equipment compared to wet milling, which softens leather by adding moisture. The choice between dry and wet milling depends on the desired leather quality, production scale, and operational priorities.

Pros and Cons of Wet Milling Leather

Wet milling leather softens the material, allowing for easier shaping and molding, which results in a smoother, more flexible final product ideal for intricate designs. However, this process can weaken the leather fibers, reducing durability and causing potential shrinkage or distortion if not properly conditioned and dried. The increased labor and time required for drying and finishing also add to production costs compared to dry milling.

Environmental Considerations in Milling Methods

Dry milling leather minimizes water usage and reduces wastewater discharge, making it a more environmentally sustainable option compared to wet milling. Wet milling consumes significant amounts of water and often generates contaminated effluents requiring extensive treatment before disposal. Choosing dry milling can lower a tannery's ecological footprint by conserving water resources and decreasing pollution.

Choosing the Right Milling Technique for Leather Manufacturing

Dry milling leather involves tumbling hides without added water, enhancing surface roughness and thickness retention, ideal for sturdy leather products like belts and bags. Wet milling uses water or steam to soften hides during tumbling, resulting in supple, pliable leather suited for garments and finer accessories. Selecting between dry and wet milling depends on the desired leather texture, flexibility, and end-use, with wet milling generally favored for softer, more flexible finishes.

Dry milling vs wet milling leather Infographic

libmatt.com

libmatt.com