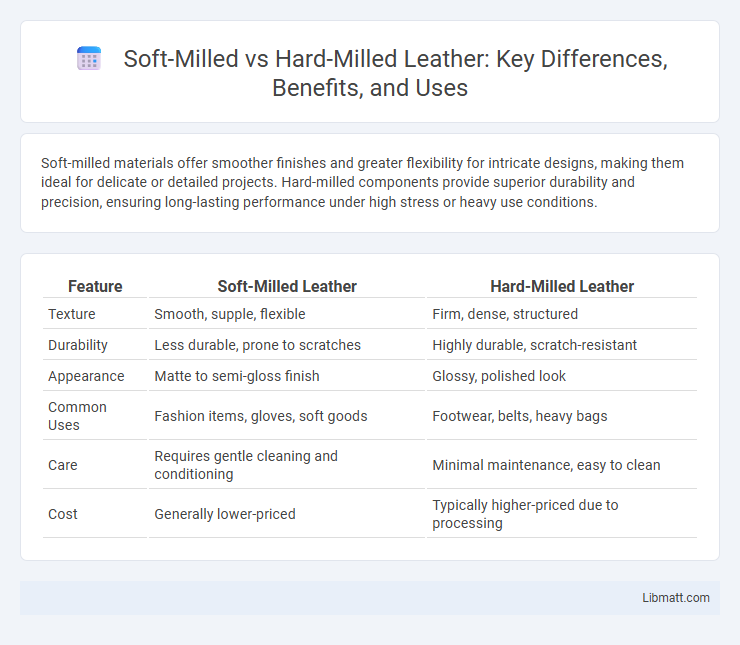

Soft-milled materials offer smoother finishes and greater flexibility for intricate designs, making them ideal for delicate or detailed projects. Hard-milled components provide superior durability and precision, ensuring long-lasting performance under high stress or heavy use conditions.

Table of Comparison

| Feature | Soft-Milled Leather | Hard-Milled Leather |

|---|---|---|

| Texture | Smooth, supple, flexible | Firm, dense, structured |

| Durability | Less durable, prone to scratches | Highly durable, scratch-resistant |

| Appearance | Matte to semi-gloss finish | Glossy, polished look |

| Common Uses | Fashion items, gloves, soft goods | Footwear, belts, heavy bags |

| Care | Requires gentle cleaning and conditioning | Minimal maintenance, easy to clean |

| Cost | Generally lower-priced | Typically higher-priced due to processing |

Introduction to Soft-Milled and Hard-Milled Products

Soft-milled products are characterized by their lower density and greater porosity, making them easier to mold and customize for various applications such as pharmaceuticals and cosmetics. Hard-milled products feature higher density and hardness, providing superior durability and structural integrity ideal for industrial uses requiring strength and precision. Understanding the distinct manufacturing processes and material properties of soft-milled versus hard-milled products is essential for selecting the appropriate product type in specialized industries.

Defining Soft-Milled vs Hard-Milled Techniques

Soft-milled techniques involve gently grinding materials at low pressures to preserve fine details and reduce surface damage, ideal for delicate components like ceramics and dentures. Hard-milled processes use high pressure and rigid milling tools to shape harder materials such as metals and high-strength plastics, ensuring precision and durability. The choice between soft-milled and hard-milled depends on material hardness, desired surface finish, and application requirements.

Materials Used in Soft-Milled and Hard-Milled Processes

Soft-milled processes primarily utilize materials such as wax, acrylic, and composite resins, which are easier to shape and allow for rapid prototyping and adjustments. Hard-milled techniques involve durable materials like zirconia, titanium, and cobalt-chromium alloys, chosen for their strength and longevity in final dental restorations or industrial components. The choice of materials directly impacts the precision, durability, and application of the milled product, with soft-milled materials suited for temporary solutions and hard-milled materials ideal for permanent fixtures.

Key Differences Between Soft-Milled and Hard-Milled

Soft-milled materials are easier to machine, resulting in smoother finishes and reduced tool wear, while hard-milled materials require more robust equipment and longer processing times due to their increased hardness. The key differences between soft-milled and hard-milled processes lie in material hardness, machine requirements, and surface quality, with soft-milling often used for preliminary shaping and hard-milling for final precision. Your choice depends on the desired durability and finish, as hard-milled components generally offer superior strength and wear resistance compared to soft-milled counterparts.

Precision and Accuracy: Which Method Performs Better?

Soft-milled machining offers higher precision due to easier cutting and less tool wear, enabling finer detail and smoother surfaces. Hard-milled machining excels in accuracy for complex geometries and harder materials, as it reduces part distortion during finishing. Your choice depends on the specific tolerances and material properties required for optimal performance.

Durability and Strength Comparisons

Soft-milled materials typically exhibit lower durability and strength compared to hard-milled counterparts due to less compact grain structure and reduced density. Hard-milled materials achieve higher hardness and wear resistance by undergoing intensive milling processes that enhance surface integrity and mechanical properties. This makes hard-milled components more suitable for high-stress applications requiring prolonged service life and resistance to deformation.

Cost Implications: Soft-Milled vs Hard-Milled

Soft-milled dental restorations typically have lower material and fabrication costs compared to hard-milled options due to easier machining and faster production times. Hard-milled restorations require more durable, expensive materials and advanced equipment, increasing overall expenses but offering superior durability and longevity. Evaluating your budget alongside the desired restoration lifespan helps determine the most cost-effective choice for your dental needs.

Applications in Dentistry and Industry

Soft-milled materials in dentistry, such as wax and resin, offer precision for temporary crowns and orthodontic models, while hard-milled options like zirconia and titanium provide durability for permanent restorations and implants. In industry, soft-milling is preferred for prototyping and tooling, allowing ease of shaping and quicker turnaround, whereas hard-milling serves heavy-duty applications requiring wear resistance and structural integrity, including aerospace and automotive components. Your choice between soft- and hard-milled materials should align with the demands of the specific dental or industrial application to optimize performance and longevity.

Pros and Cons of Soft-Milled and Hard-Milled Methods

Soft-milled methods offer precise, smooth finishes with reduced tool wear, making them ideal for delicate materials and intricate designs, but may result in longer production times and less durability compared to hard-milled approaches. Hard-milled techniques provide superior strength and wear resistance for components, supporting high-volume, high-speed manufacturing, yet they can cause increased tool degradation and surface roughness. Balancing the pros and cons of soft-milled and hard-milled processes helps you select the best machining method based on your project's material hardness, design complexity, and production requirements.

Choosing the Right Milling Technique for Your Needs

Soft-milled materials offer easier machining and faster production times, ideal for prototypes and small runs, while hard-milled components provide superior durability and precision for high-performance applications. Your choice depends on factors like the required surface finish, material hardness, and intended use, with soft-milling favoring flexibility and hard-milling ensuring long-term wear resistance. Selecting the right milling technique optimizes manufacturing efficiency and product quality based on your specific project demands.

Soft-milled vs hard-milled Infographic

libmatt.com

libmatt.com