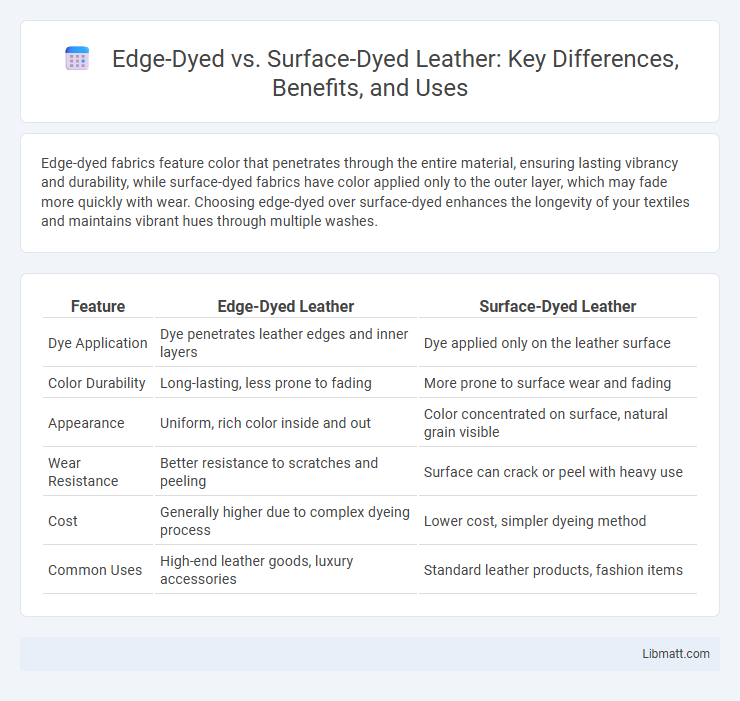

Edge-dyed fabrics feature color that penetrates through the entire material, ensuring lasting vibrancy and durability, while surface-dyed fabrics have color applied only to the outer layer, which may fade more quickly with wear. Choosing edge-dyed over surface-dyed enhances the longevity of your textiles and maintains vibrant hues through multiple washes.

Table of Comparison

| Feature | Edge-Dyed Leather | Surface-Dyed Leather |

|---|---|---|

| Dye Application | Dye penetrates leather edges and inner layers | Dye applied only on the leather surface |

| Color Durability | Long-lasting, less prone to fading | More prone to surface wear and fading |

| Appearance | Uniform, rich color inside and out | Color concentrated on surface, natural grain visible |

| Wear Resistance | Better resistance to scratches and peeling | Surface can crack or peel with heavy use |

| Cost | Generally higher due to complex dyeing process | Lower cost, simpler dyeing method |

| Common Uses | High-end leather goods, luxury accessories | Standard leather products, fashion items |

Introduction to Dyeing Techniques

Edge-dyed fabrics feature color applied primarily to the fabric's edges, creating a gradient or ombre effect that emphasizes texture and depth. Surface-dyed techniques involve applying dye directly to the fabric's top layer, allowing for precise patterns and vibrant colors without penetrating the entire material. Both dyeing methods influence fabric aesthetics and functionality, impacting design choices in fashion and interior textiles.

What is Edge Dyeing?

Edge dyeing is a textile coloring technique where dye is applied specifically to the edges of fabric or yarn bundles, resulting in a distinctive gradient or ombre effect. This method enhances depth and visual texture by concentrating color saturation at the borders while leaving the interior lighter or undyed. Edge dyeing is commonly used in specialty fabrics and handcrafted textiles to create unique patterns and highlight the material's structural nuances.

What is Surface Dyeing?

Surface dyeing is a textile coloring method where dye is applied only to the outer layer of the fabric, allowing the base fibers to remain largely undyed. This technique creates a unique texture and visual effect by concentrating color on the fabric's surface, often resulting in a softer hand feel and subtle color variations. Surface dyeing is commonly used in fashion and upholstery to achieve a rich, dimensional appearance without fully saturating the entire material.

Key Differences: Edge-Dyed vs Surface-Dyed

Edge-dyed fabrics feature color applied mainly at the edges, creating unique shading and a vintage, worn-in look, while surface-dyed textiles have dye uniformly absorbed into the fibers, resulting in consistent and long-lasting coloration. Edge-dyeing often allows for more intricate, artistic effects and color gradients that appear naturally faded over time. Surface-dyeing provides better colorfastness and resistance to fading, making it ideal for products requiring durability and uniform appearance.

Durability Comparison

Edge-dyed fabrics exhibit greater durability than surface-dyed fabrics due to dye penetration through the entire material thickness, reducing fading and wear over time. Surface-dyed fabrics only have color applied on the exterior, making them more prone to peeling, cracking, and color loss under frequent use or washing. The comprehensive coloration of edge-dyed textiles ensures longer-lasting vibrancy and resistance to abrasion, ideal for high-traffic applications.

Visual and Aesthetic Impact

Edge-dyed fabrics showcase color saturation that penetrates through layers, creating a rich, multidimensional look with vibrant, lasting hues. Surface-dyed textiles display color only on the fabric's exterior, resulting in a flatter, more uniform appearance that can fade faster. Your choice between edge-dyed and surface-dyed will directly influence the depth and durability of the visual effect in your project.

Applications and Use Cases

Edge-dyed fabrics are primarily used in fashion and high-end upholstery where precise color placement is essential for creating striped, patterned, or jacquard designs. Surface-dyed textiles find common application in home furnishings, such as curtains and cushions, due to their ability to achieve vibrant color saturation and intricate surface patterns. Both dyeing techniques serve distinct purposes: edge-dyeing excels in structured, design-driven applications, while surface-dyeing is favored for decorative, large-scale color coverage.

Maintenance and Longevity

Edge-dyed fabrics maintain color integrity longer because the dye penetrates through the entire fiber, reducing visible wear and fading over time. Surface-dyed materials are more prone to color loss and surface wear due to their dye remaining on the outer layer, which can degrade with repeated washing or abrasion. Proper maintenance of edge-dyed textiles involves standard cleaning methods, while surface-dyed fabrics require gentler care to preserve their appearance and extend longevity.

Cost and Production Considerations

Edge-dyed fabrics typically involve a longer production time and higher labor costs due to the meticulous dyeing process along the fabric edges, making them more expensive compared to surface-dyed fabrics. Surface dyeing is generally faster and more cost-effective, as it allows for larger batch processing and straightforward application techniques. You should weigh these cost and production differences when selecting the dyeing method that best fits your budget and manufacturing timeline.

Choosing the Right Technique for Your Needs

Edge-dyed fabrics offer vibrant, long-lasting color that penetrates the material, making them ideal for items requiring durability and deep hues. Surface-dyed techniques coat only the fabric's outer layer, providing quicker production and a wider range of design options but may fade faster with repeated washing. Understanding your project's longevity, appearance, and budget needs ensures you select the dyeing method best suited to your requirements.

Edge-dyed vs surface-dyed Infographic

libmatt.com

libmatt.com