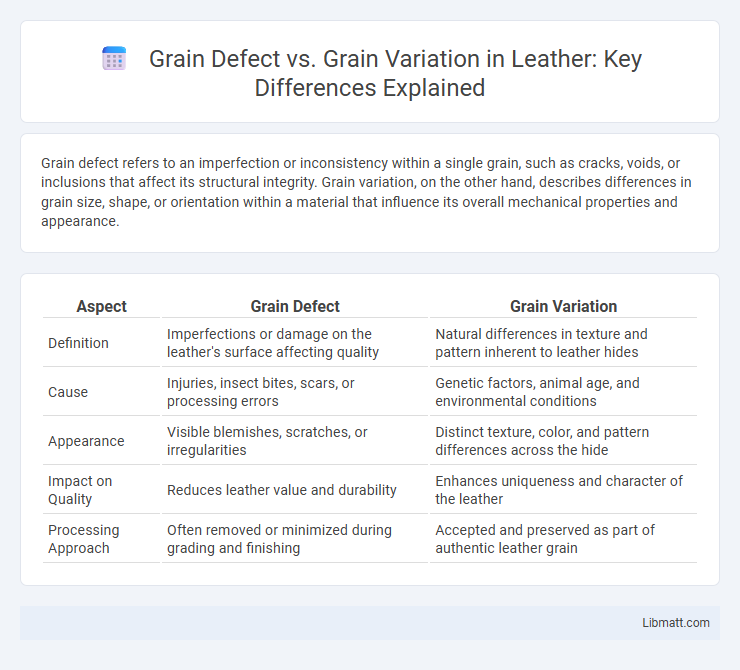

Grain defect refers to an imperfection or inconsistency within a single grain, such as cracks, voids, or inclusions that affect its structural integrity. Grain variation, on the other hand, describes differences in grain size, shape, or orientation within a material that influence its overall mechanical properties and appearance.

Table of Comparison

| Aspect | Grain Defect | Grain Variation |

|---|---|---|

| Definition | Imperfections or damage on the leather's surface affecting quality | Natural differences in texture and pattern inherent to leather hides |

| Cause | Injuries, insect bites, scars, or processing errors | Genetic factors, animal age, and environmental conditions |

| Appearance | Visible blemishes, scratches, or irregularities | Distinct texture, color, and pattern differences across the hide |

| Impact on Quality | Reduces leather value and durability | Enhances uniqueness and character of the leather |

| Processing Approach | Often removed or minimized during grading and finishing | Accepted and preserved as part of authentic leather grain |

Introduction to Grain Defect and Grain Variation

Grain defects refer to specific irregularities or imperfections within the crystalline structure of a material, such as dislocations, inclusions, or voids, which can significantly affect mechanical properties and performance. Grain variation denotes the natural differences in grain size, shape, and orientation that occur during material processing, influencing strength, toughness, and durability. Understanding both grain defect and grain variation is crucial for optimizing material quality and ensuring your product's reliability in demanding applications.

Defining Grain Defects in Materials

Grain defects in materials refer to imperfections or irregularities within the crystalline structure, including dislocations, vacancies, and grain boundary impurities that affect mechanical and electrical properties. These defects disrupt the uniformity of grains, leading to weakened material strength, reduced corrosion resistance, or altered conductivity. Understanding grain defects helps you optimize material performance by controlling manufacturing processes and improving quality control.

Understanding Grain Variation: Overview

Grain variation refers to the natural differences in size, shape, and orientation of individual grains within a polycrystalline material, influencing mechanical properties and material performance. This variation is critical for understanding the material's behavior under stress, as it affects grain boundary interactions and deformation mechanisms. Unlike grain defects, which are irregularities or disruptions within the grains, grain variation encompasses the inherent heterogeneity that occurs during material formation and processing.

Causes of Grain Defects

Grain defects primarily result from irregularities during the growth process, such as incomplete grain development, environmental stress, or poor harvest techniques. Unlike natural grain variation, which reflects normal differences in size, shape, and color, grain defects are caused by factors including pest damage, fungal infections, and mechanical injury. Understanding these causes helps you identify and manage defects to maintain grain quality and reduce losses.

Factors Influencing Grain Variation

Factors influencing grain variation include genetics, environmental conditions, and processing methods, which collectively impact the uniformity of grain size, shape, and texture. Variations in temperature, moisture levels, and soil quality during growth contribute significantly to inconsistent grain development, while milling and storage practices further affect grain integrity. Understanding these factors helps you optimize grain quality by minimizing defects and maintaining consistent grain attributes.

Impact of Grain Defects on Material Performance

Grain defects, such as dislocations, vacancies, and grain boundary impurities, significantly degrade material performance by reducing mechanical strength, increasing brittleness, and accelerating corrosion. These defects disrupt atomic cohesion and impede dislocation motion, causing premature failure under stress. In contrast, grain variation relates to grain size distribution, which can influence toughness and ductility but does not inherently cause catastrophic material degradation like grain defects.

Benefits and Drawbacks of Grain Variation

Grain variation in materials, such as metals or wood, can influence mechanical properties, offering benefits like enhanced toughness and resistance to crack propagation due to heterogeneous grain structures. However, drawbacks include inconsistent performance and potential weak points where grain size differences cause stress concentration, leading to reduced structural reliability. Understanding and controlling grain variation enables optimization of strength and durability in engineering applications.

Detection and Analysis Methods

Grain defect detection relies on imaging techniques such as scanning electron microscopy and X-ray diffraction to identify irregularities in grain boundaries, while grain variation analysis utilizes statistical methods like grain size distribution and texture analysis to quantify differences in grain structure. Advanced machine learning algorithms enhance both detection and analysis by automating pattern recognition and classification from large datasets. Combining these methods improves the accuracy of assessing material properties and predicting performance inconsistencies caused by microstructural heterogeneities.

Prevention and Control Strategies

Grain defect prevention relies on accurately identifying causes such as pest infestation, moisture imbalance, and improper storage conditions, which can be mitigated by controlled drying environments and pest management protocols. Grain variation control focuses on maintaining uniform quality through consistent harvesting times, precise genetic selection, and standardized milling processes, ensuring your product meets quality specifications. Implementing comprehensive monitoring systems and quality control measures significantly reduces the risk of defects while promoting uniform grain attributes.

Conclusion: Key Differences and Implications

Grain defect refers to specific imperfections within a single grain, such as dislocations or vacancies, whereas grain variation describes differences in size, orientation, or structure between multiple grains in a material. Understanding these distinctions is crucial for analyzing material properties, as grain defects can directly affect mechanical strength and conductivity, while grain variations influence overall texture and durability. Your ability to optimize material performance depends on accurately identifying and managing both grain defects and grain variations in metallurgical processes.

Grain defect vs grain variation Infographic

libmatt.com

libmatt.com