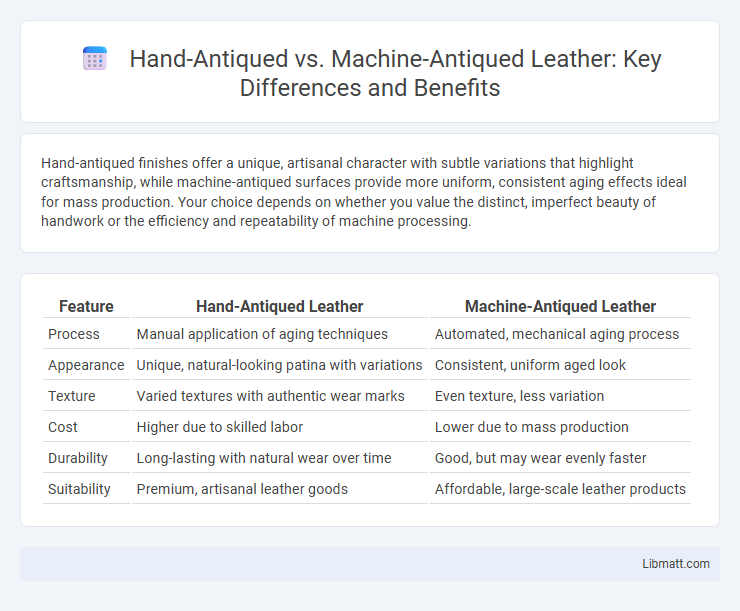

Hand-antiqued finishes offer a unique, artisanal character with subtle variations that highlight craftsmanship, while machine-antiqued surfaces provide more uniform, consistent aging effects ideal for mass production. Your choice depends on whether you value the distinct, imperfect beauty of handwork or the efficiency and repeatability of machine processing.

Table of Comparison

| Feature | Hand-Antiqued Leather | Machine-Antiqued Leather |

|---|---|---|

| Process | Manual application of aging techniques | Automated, mechanical aging process |

| Appearance | Unique, natural-looking patina with variations | Consistent, uniform aged look |

| Texture | Varied textures with authentic wear marks | Even texture, less variation |

| Cost | Higher due to skilled labor | Lower due to mass production |

| Durability | Long-lasting with natural wear over time | Good, but may wear evenly faster |

| Suitability | Premium, artisanal leather goods | Affordable, large-scale leather products |

Introduction to Antiquing Techniques

Hand-antiqued techniques involve artisans manually applying patinas and distressing to create unique, authentic finishes that enhance wood grain and texture. Machine-antiqued methods use automated processes to replicate aged looks with consistent patterns, suitable for mass production but often lacking the nuanced character of handmade work. Your choice between these techniques affects the visual appeal and individuality of antique-style furniture or decor.

Understanding Hand-Antiqued Finishes

Hand-antiqued finishes are characterized by meticulous craftsmanship, where artisans apply distressing techniques individually to create unique, irregular patterns that enhance the wood's natural grain and character. This process ensures that no two pieces are identical, adding a personalized vintage appeal that machine-antiqued finishes often lack. Understanding hand-antiqued finishes helps you appreciate the skill and time invested in achieving authentic aged textures, making your furniture or decor stand out with genuine, artisanal beauty.

Exploring Machine-Antiqued Methods

Machine-antiqued methods utilize advanced technology to replicate the rustic charm of hand-antiqued finishes with precision and efficiency, offering consistent texture and color across large surfaces. These techniques often involve automated tools like sanders, brushes, or lasers to create aged effects, reducing labor costs and production time while maintaining high-quality results. When choosing your finish, machine-antiquing ensures uniformity and scalability, making it ideal for commercial applications where traditional hand-antiquing may be impractical.

Key Differences: Hand vs. Machine Antiquing

Hand-antiqued finishes exhibit unique, irregular patterns created by skilled artisans using traditional tools, resulting in a rich, authentic texture valued in custom furniture and high-end cabinetry. Machine-antiqued processes rely on automated techniques like sanding and embossing to produce consistent, repeatable effects ideal for large-scale manufacturing and budget-conscious projects. The primary distinctions lie in the level of detail, customization, and cost, with hand-antiquing offering bespoke character and machine-antiquing providing efficiency and uniformity.

Authenticity and Character in Finishes

Hand-antiqued finishes exhibit unique variations and subtle imperfections that enhance authenticity and character, reflecting skilled craftsmanship and time-honored techniques. Machine-antiqued finishes offer uniformity and consistency but often lack the depth and individual charm found in hand-applied textures. Collectors and designers value hand-antiqued pieces for their distinctive patina and natural aging effects that cannot be exactly replicated by automated methods.

Cost Comparison: Manual vs. Mechanical Antiquing

Hand-antiqued finishes generally incur higher costs due to the extensive labor and skilled craftsmanship involved in manually distressing each piece, resulting in unique and detailed textures. Machine-antiqued processes offer more cost-effective production by utilizing automated techniques that replicate antiqued effects rapidly and consistently, reducing labor expenses. The price difference reflects the trade-off between the artisanal quality of hand-antiquing and the efficiency and scalability of mechanical methods.

Durability and Longevity of Antiqued Surfaces

Hand-antiqued surfaces typically offer superior durability and longevity because the artisan applies traditional techniques that create deeper, more authentic wear patterns resistant to fading and chipping. Machine-antiqued finishes may look uniform but often lack the depth needed to withstand heavy use, leading to quicker deterioration over time. Choosing hand-antiqued options ensures your surfaces maintain their antique charm and structural integrity for years to come.

Aesthetic Outcomes and Variations

Hand-antiqued finishes create unique, authentic textures and color variations due to the artisan's skillful, individualized approach, resulting in rich depth and character expertly tailored to each piece. Machine-antiqued processes offer more consistent and uniform patterns, ensuring predictability but often lacking the subtle imperfections that give handcrafted finishes their charm and distinctiveness. Your choice between these methods influences the aesthetic outcome, with hand-antiquing delivering exclusive artistry and machines providing reliable, repeatable designs.

Choosing the Right Antiquing Method

Hand-antiqued finishes offer unique, artisanal character with subtle variations, ideal for custom, high-end furniture pieces where individuality is prized. Machine-antiqued methods provide consistent, uniform results suited for large-scale production, ensuring cost efficiency without sacrificing style. Selecting the right antiquing technique depends on desired aesthetic authenticity, budget constraints, and production volume requirements.

Conclusion: Hand-Antiqued or Machine-Antiqued?

Hand-antiqued finishes offer unique, handcrafted detail and an authentic aged appearance that enhances the character of wood surfaces, making them ideal for custom, high-end furniture. Machine-antiqued processes provide consistent, uniform finishes suitable for large-scale production and budget-conscious projects but may lack the nuanced texture and depth of hand-applied antiquing. Choosing between hand-antiqued and machine-antiqued depends on the desired aesthetic, project scale, and budget, with hand-antiqued favored for artisanal quality and machine-antiqued for efficient replication.

Hand-antiqued vs machine-antiqued Infographic

libmatt.com

libmatt.com