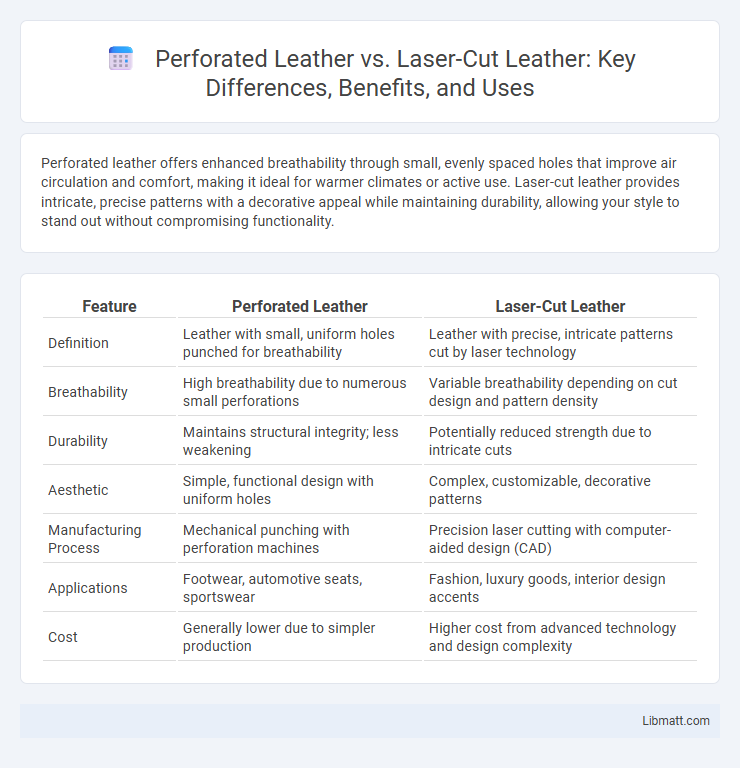

Perforated leather offers enhanced breathability through small, evenly spaced holes that improve air circulation and comfort, making it ideal for warmer climates or active use. Laser-cut leather provides intricate, precise patterns with a decorative appeal while maintaining durability, allowing your style to stand out without compromising functionality.

Table of Comparison

| Feature | Perforated Leather | Laser-Cut Leather |

|---|---|---|

| Definition | Leather with small, uniform holes punched for breathability | Leather with precise, intricate patterns cut by laser technology |

| Breathability | High breathability due to numerous small perforations | Variable breathability depending on cut design and pattern density |

| Durability | Maintains structural integrity; less weakening | Potentially reduced strength due to intricate cuts |

| Aesthetic | Simple, functional design with uniform holes | Complex, customizable, decorative patterns |

| Manufacturing Process | Mechanical punching with perforation machines | Precision laser cutting with computer-aided design (CAD) |

| Applications | Footwear, automotive seats, sportswear | Fashion, luxury goods, interior design accents |

| Cost | Generally lower due to simpler production | Higher cost from advanced technology and design complexity |

Introduction to Perforated Leather and Laser-Cut Leather

Perforated leather features small, uniformly punched holes designed for enhanced breathability and comfort, commonly used in automotive and fashion industries. Laser-cut leather employs precise, intricate patterns created by laser technology, offering greater design versatility and detailed aesthetics. Your choice between these materials depends on whether ventilation or decorative detail is the priority in your leather product.

What is Perforated Leather?

Perforated leather features small, evenly spaced holes punched through the material to enhance breathability and comfort, frequently used in automotive seats and fashion accessories. This technique improves air circulation, reducing heat buildup and moisture, making it ideal for warmer climates or active use. Understanding perforated leather helps you make informed choices when seeking stylish yet functional leather products.

What is Laser-Cut Leather?

Laser-cut leather is a material precisely crafted using advanced laser technology to create intricate and consistent patterns by vaporizing the surface without damaging the surrounding areas. This method allows for highly detailed designs that are difficult to achieve with traditional perforation, offering enhanced aesthetic appeal and breathability. Your choice of laser-cut leather ensures superior customization and durability compared to conventional perforated leather.

Manufacturing Process Comparison

Perforated leather is crafted through a mechanical punching process that creates uniform holes using metal dies, offering breathability and texture. Laser-cut leather involves using high-precision laser beams to intricately cut patterns, allowing for detailed and customizable designs without additional tooling. Understanding these distinct manufacturing techniques helps you choose the appropriate material based on the desired aesthetic, durability, and production efficiency.

Design and Aesthetic Differences

Perforated leather features uniform, punched holes that provide a classic, breathable texture often used in automotive and fashion upholstery for ventilation and subtle detailing. Laser-cut leather allows for intricate, precise patterns with complex shapes and customized motifs, offering a modern and decorative aesthetic that can range from delicate filigree to bold graphics. The design difference lies in perforation's uniform simplicity versus laser cutting's versatility and artistic potential, impacting the overall visual appeal and tactile experience of leather products.

Durability and Performance

Perforated leather offers enhanced breathability and moisture management, contributing to long-lasting comfort and durability in footwear and upholstery applications. Laser-cut leather provides precise, intricate patterns with consistent thickness, maintaining structural integrity while offering superior aesthetic performance. Both types balance durability with airflow, but perforated leather typically withstands wear better in high-friction environments due to its traditional manufacturing process.

Breathability and Comfort

Perforated leather features small punched holes that significantly improve breathability by allowing air to circulate, enhancing comfort in warm conditions. Laser-cut leather offers precise and intricate patterns with varying hole sizes, optimizing ventilation while maintaining material strength. Both techniques enhance airflow compared to solid leather, but perforated leather generally provides more consistent breathability for long-term comfort.

Applications in Fashion and Automotive

Perforated leather offers enhanced breathability and comfort, making it ideal for automotive seating and high-end fashion accessories like shoes and jackets. Laser-cut leather enables precise, intricate designs, favored in luxury fashion for creating detailed patterns on apparel and handbags. Both techniques improve aesthetic appeal while addressing functional needs in vehicle interiors and fashion products.

Cost Considerations

Perforated leather typically incurs lower production costs due to its conventional mechanical punching method, making it more budget-friendly for large-scale manufacturing. Laser-cut leather involves advanced technology with higher initial investment and maintenance expenses, reflecting in its premium pricing. When evaluating leather options, cost considerations depend on production scale, desired precision, and aesthetic requirements.

Which Leather Type Should You Choose?

Perforated leather offers enhanced breathability and moisture control, making it ideal for vehicle seats or breathable fashion items, while laser-cut leather provides intricate, precise designs suitable for high-end upholstery or detailed accessories. Choose perforated leather if comfort and ventilation are priorities; opt for laser-cut leather when aesthetic detail and unique patterns are desired. Consider the final use, maintenance, and durability needs to determine the best leather type for your project.

Perforated leather vs laser-cut leather Infographic

libmatt.com

libmatt.com