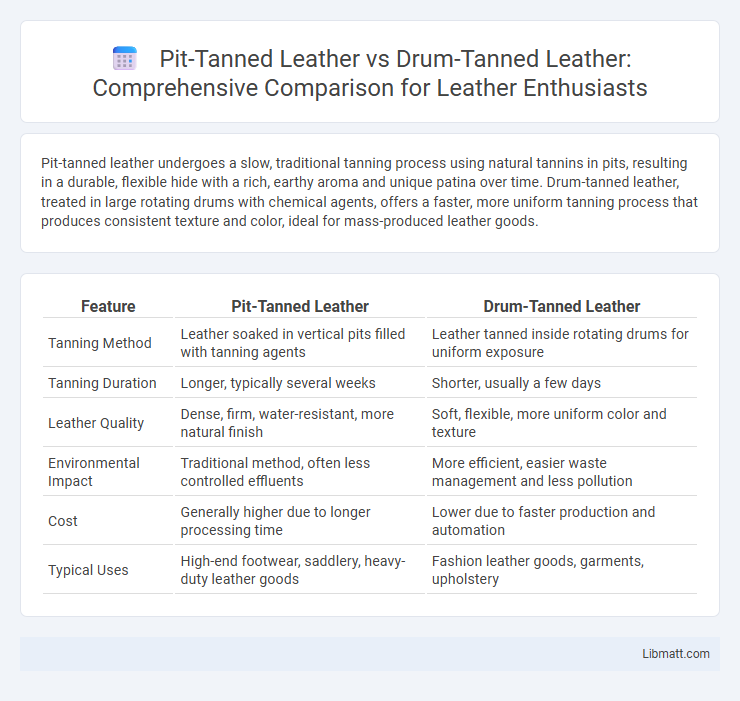

Pit-tanned leather undergoes a slow, traditional tanning process using natural tannins in pits, resulting in a durable, flexible hide with a rich, earthy aroma and unique patina over time. Drum-tanned leather, treated in large rotating drums with chemical agents, offers a faster, more uniform tanning process that produces consistent texture and color, ideal for mass-produced leather goods.

Table of Comparison

| Feature | Pit-Tanned Leather | Drum-Tanned Leather |

|---|---|---|

| Tanning Method | Leather soaked in vertical pits filled with tanning agents | Leather tanned inside rotating drums for uniform exposure |

| Tanning Duration | Longer, typically several weeks | Shorter, usually a few days |

| Leather Quality | Dense, firm, water-resistant, more natural finish | Soft, flexible, more uniform color and texture |

| Environmental Impact | Traditional method, often less controlled effluents | More efficient, easier waste management and less pollution |

| Cost | Generally higher due to longer processing time | Lower due to faster production and automation |

| Typical Uses | High-end footwear, saddlery, heavy-duty leather goods | Fashion leather goods, garments, upholstery |

Introduction to Pit-Tanned and Drum-Tanned Leather

Pit-tanned leather undergoes a traditional, slow tanning process using natural tannins in underground pits, resulting in a durable, firm, and water-resistant material. Drum-tanned leather is produced by tumbling hides in rotating drums with tanning agents, accelerating the process and yielding softer, more flexible leather. Understanding these distinct methods helps you choose the best leather type based on texture, durability, and intended use.

Historical Background of Leather Tanning Methods

Pit-tanned leather represents an ancient method dating back thousands of years, where hides are submerged in natural tannin-rich solutions within pits to slowly preserve and soften the material. Drum-tanned leather, a more modern innovation from the 19th century, uses rotating drums to evenly tan hides with chemical agents, significantly speeding up the process while ensuring consistent quality. Understanding these historic leather tanning methods helps you appreciate the evolution of craftsmanship and the distinct textures each technique imparts.

Overview of the Pit-Tanning Process

Pit-tanning involves immersing animal hides in large, shallow pits filled with tannin-rich natural substances such as tree bark or leaves for several months, allowing slow absorption and deep penetration of tannins. This traditional method produces leather with a unique character, durability, and rich patina due to prolonged chemical reactions between tannins and collagen fibers. Unlike faster alternatives, pit-tanning emphasizes natural, ecological processing, resulting in thicker, more flexible leather ideal for premium artisanal products.

Overview of the Drum-Tanning Process

Drum-tanned leather undergoes a mechanical tanning process where hides are placed inside large, rotating drums filled with tanning agents, ensuring even penetration and faster processing compared to traditional methods. This method enhances leather's softness, flexibility, and durability by uniformly treating the fibers, which results in a more consistent texture and color. The rotary motion of the drum accelerates chemical absorption, reducing overall tanning time and improving production efficiency in leather manufacturing.

Key Differences in Material Quality

Pit-tanned leather undergoes a slow, natural tanning process using organic tannins soaked in pits, resulting in thicker, more durable material with a firm texture and rich color depth. Drum-tanned leather is treated faster in rotating drums with chemically controlled solutions, producing a softer, more uniform finish suited for consistent quality and flexibility. Your choice depends on whether you prioritize longevity and ruggedness (pit-tanned) or even texture and rapid production (drum-tanned) for your leather goods.

Durability and Longevity Comparison

Pit-tanned leather boasts exceptional durability due to its slow, natural tanning process that deeply preserves the hide's fibers, resulting in leather that ages beautifully and lasts for decades with minimal wear. Drum-tanned leather, while more uniform and quicker to produce, often lacks the same depth of fiber penetration, making it more prone to early cracking and fading under heavy use. Your choice should consider that pit-tanned leather offers superior longevity ideal for long-term investment in high-quality goods.

Environmental Impact of Each Tanning Method

Pit-tanned leather employs natural tannins from tree bark and plants, resulting in a slower but eco-friendlier process with minimal chemical waste and low water pollution. Drum-tanned leather, though faster and more cost-effective, often uses synthetic chemicals that can lead to higher environmental contamination and increased water usage. Overall, pit tanning is considered a more sustainable method, emphasizing reduced ecological footprint compared to the industrial-scale pollution associated with drum tanning.

Aesthetic and Texture Variations

Pit-tanned leather features a more rustic, uneven texture with a natural, matte finish that enhances its rugged aesthetic, often preferred for artisanal and vintage-style products. Drum-tanned leather offers a smoother, more uniform surface with a glossy or semi-glossy sheen, resulting in a polished and consistent appearance ideal for high-end fashion and luxury goods. Understanding these aesthetic and texture variations can help you choose the perfect leather type that aligns with your desired style and product functionality.

Cost and Availability for Consumers

Pit-tanned leather typically incurs higher costs due to its labor-intensive, time-consuming process and limited production scale, making it less available and more niche for consumers. Drum-tanned leather benefits from mechanized processing, resulting in lower costs and greater availability in mainstream markets. Consumers looking for affordable and widely accessible leather products often find drum-tanned options more suitable compared to the premium pricing and scarcity of pit-tanned leather.

Choosing the Right Leather for Your Needs

Pit-tanned leather offers a slower, traditional tanning process using natural tannins, resulting in a firmer, more durable material ideal for heavy-duty applications like saddlery and boots. Drum-tanned leather, processed in rotating drums with chemical tannins, provides a softer, more pliable finish suitable for fashion accessories and garments requiring greater flexibility. Selecting between pit-tanned and drum-tanned leather depends on the desired durability, texture, and flexibility tailored to specific functional needs and product longevity.

Pit-tanned leather vs drum-tanned leather Infographic

libmatt.com

libmatt.com