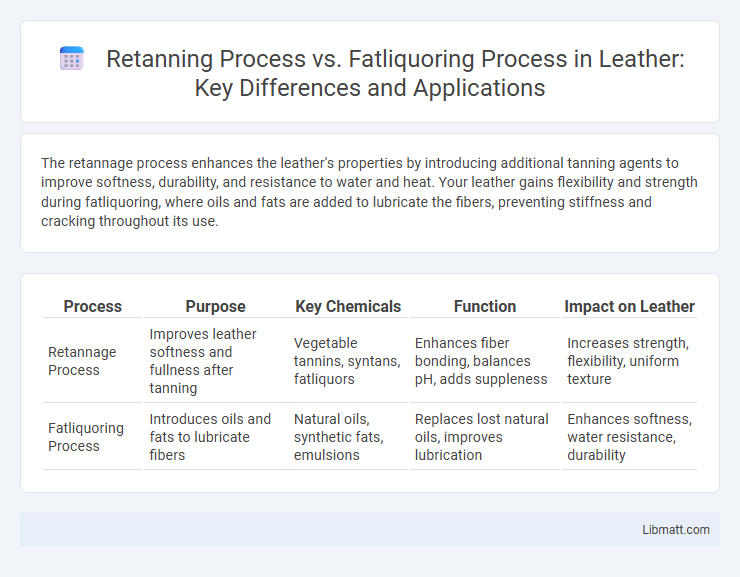

The retannage process enhances the leather's properties by introducing additional tanning agents to improve softness, durability, and resistance to water and heat. Your leather gains flexibility and strength during fatliquoring, where oils and fats are added to lubricate the fibers, preventing stiffness and cracking throughout its use.

Table of Comparison

| Process | Purpose | Key Chemicals | Function | Impact on Leather |

|---|---|---|---|---|

| Retannage Process | Improves leather softness and fullness after tanning | Vegetable tannins, syntans, fatliquors | Enhances fiber bonding, balances pH, adds suppleness | Increases strength, flexibility, uniform texture |

| Fatliquoring Process | Introduces oils and fats to lubricate fibers | Natural oils, synthetic fats, emulsions | Replaces lost natural oils, improves lubrication | Enhances softness, water resistance, durability |

Introduction to Leather Processing

Retannage and fatliquoring are critical stages in leather processing that significantly influence the final product's quality and characteristics. Retannage involves re-tanning the leather to enhance its fullness, softness, and strength by applying additional tanning agents after the primary tanning process. Fatliquoring introduces oils and fats to lubricate the fibers, improving flexibility, water resistance, and durability, thereby ensuring Your leather goods maintain optimal performance and longevity.

Overview of Retannage and Fatliquoring

Retannage is a crucial leather processing stage that refines and stabilizes the tanned leather by reintroducing tanning agents such as synthetic tannins or oils to enhance flexibility and durability. Fatliquoring involves the infusion of oils and fats into the leather fibers to lubricate and soften the material, improving its suppleness and water resistance. Both processes are essential to achieve desired leather quality, with retannage focusing on structural enhancement and fatliquoring on texture and comfort.

Purpose of Retannage in Leather Making

Retannage enhances leather quality by improving its softness, fullness, and grain structure after the initial tanning process. It stabilizes the collagen fibers, ensuring better dye uptake and enhancing durability and feel. Unlike fatliquoring, which primarily adds oils and lubricants to maintain flexibility and prevent stiffness, retannage focuses on refining the leather's physical and aesthetic properties for high-quality finished products.

Key Chemicals Used in Retannage

Retannage involves using key chemicals such as synthetic tannins, resins, and oils to improve leather softness, fullness, and grain firmness, enhancing its physical properties post-primary tanning. Fatliquoring relies on natural and synthetic oils, emulsifiers, and lubricants to introduce fat molecules, ensuring leather flexibility and water resistance. Your choice between retannage and fatliquoring depends on the desired leather characteristics and final performance requirements.

Function and Benefits of Fatliquoring

Fatliquoring enhances leather flexibility and softness by replenishing oils lost during tanning, ensuring improved durability and comfort. This process improves your leather's water resistance and prevents stiffness, making it more supple and wearable. Compared to retannage, which primarily adjusts leather properties through additional tanning agents, fatliquoring directly restores essential fats crucial for leather's long-lasting quality.

Core Differences between Retannage and Fatliquoring

Retannage primarily focuses on improving the leather's softness, fullness, and color uniformity by applying additional tanning agents after the initial tanning. Fatliquoring, on the other hand, involves the introduction of oils and lubricants to the leather fibers, enhancing flexibility, water resistance, and overall suppleness. While retannage adjusts the chemical tanning state, fatliquoring fine-tunes the leather's physical and tactile properties by replenishing natural fats removed during tanning.

Step-by-Step Retannage Process

The retannage process involves treating chrome-tanned leather with additional tanning agents such as syntans, aldehydes, or vegetable extracts to improve softness, fullness, and dye receptivity. Step-by-step, the retannage begins with draining the chrome liquor, followed by neutralizing the leather with basifying agents, then adding retanning agents in controlled doses under agitation to ensure uniform penetration, and finally fixing and washing to stabilize the leather's structure. This process enhances leather quality after primary tanning and prepares it for subsequent fatliquoring, which infuses oils and fats to lubricate fibers and increase flexibility.

Detailed Fatliquoring Procedure

The fatliquoring process involves the precise introduction of oils and fats into the leather matrix to impart softness, flexibility, and improved durability, following the retannage phase that stabilizes the leather structure. Fatliquoring agents, commonly sulfated oils or synthetic emulsions, are uniformly dispersed in the leather, with temperature and pH carefully controlled to optimize absorption and bonding within collagen fibers. This stage is critical for enhancing leather's tactile qualities and resistance to cracking, setting it apart from the retannage process, which primarily focuses on refining and strengthening the tanned leather through additional tanning agents.

Impact on Final Leather Properties

Retannage enhances leather softness and fullness by introducing additional tanning agents that improve fiber structure and durability, resulting in better wrinkle resistance and water repellency. Fatliquoring imparts essential lubricants and oils, increasing flexibility, tensile strength, and moisture retention, which prevents the leather from becoming brittle. Together, these processes optimize leather's overall texture, suppleness, and longevity, crucial for high-quality leather products.

Choosing Between Retannage and Fatliquoring for Specific Applications

Retannage and fatliquoring serve distinct roles in leather processing, with retannage focusing on restoring leather strength and fullness through additional tanning agents, while fatliquoring enhances softness and flexibility by reintroducing oils and fats. Selecting between retannage and fatliquoring depends on the end-use requirements, where retannage suits applications needing improved durability and structural integrity, such as footwear and industrial leather goods. Fatliquoring is preferred for producing supple, pliable leather used in fashion apparel and upholstery, emphasizing tactile comfort and aesthetic appeal.

Retannage process vs fatliquoring process Infographic

libmatt.com

libmatt.com