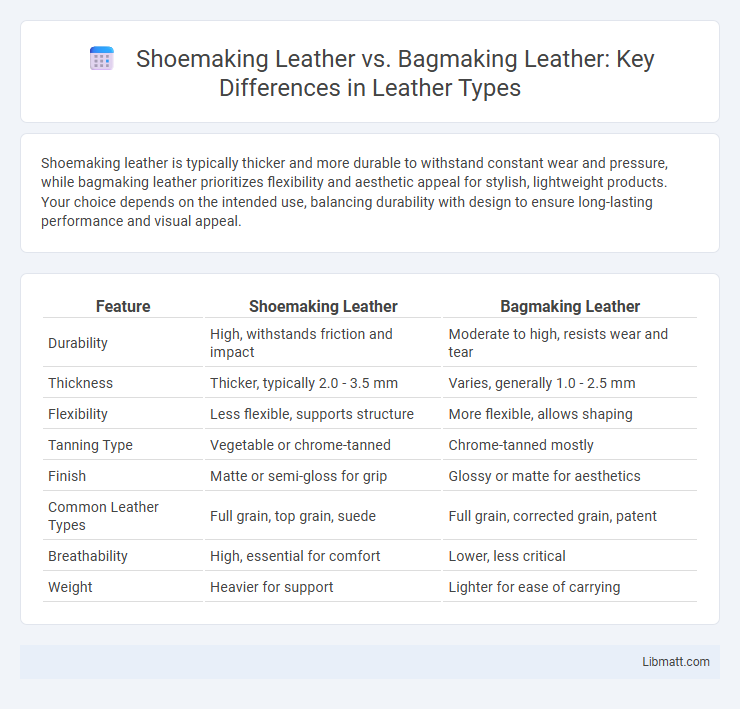

Shoemaking leather is typically thicker and more durable to withstand constant wear and pressure, while bagmaking leather prioritizes flexibility and aesthetic appeal for stylish, lightweight products. Your choice depends on the intended use, balancing durability with design to ensure long-lasting performance and visual appeal.

Table of Comparison

| Feature | Shoemaking Leather | Bagmaking Leather |

|---|---|---|

| Durability | High, withstands friction and impact | Moderate to high, resists wear and tear |

| Thickness | Thicker, typically 2.0 - 3.5 mm | Varies, generally 1.0 - 2.5 mm |

| Flexibility | Less flexible, supports structure | More flexible, allows shaping |

| Tanning Type | Vegetable or chrome-tanned | Chrome-tanned mostly |

| Finish | Matte or semi-gloss for grip | Glossy or matte for aesthetics |

| Common Leather Types | Full grain, top grain, suede | Full grain, corrected grain, patent |

| Breathability | High, essential for comfort | Lower, less critical |

| Weight | Heavier for support | Lighter for ease of carrying |

Introduction to Leather Types in Shoemaking and Bagmaking

Shoemaking leather typically requires thicker, more durable hides such as full-grain or top-grain leather, which provide strength, flexibility, and resistance to wear essential for footwear. Bagmaking leather often utilizes softer, more pliable types like vegetable-tanned or chrome-tanned leather, chosen for their ability to mold easily and maintain aesthetic appeal through intricate designs. Both crafts prioritize leather quality but differ significantly in thickness, finish, and treatment to meet specific functional and stylistic demands.

Key Differences Between Shoemaking and Bagmaking Leather

Shoemaking leather typically features higher durability, thicker hides, and greater flexibility to withstand constant bending and wear, whereas bagmaking leather prioritizes surface smoothness and aesthetic appeal with lighter, softer materials suited for carrying and style. Shoemaking leather often includes full-grain or top-grain types to ensure longevity and support foot structure, while bag leather may use corrected grain or embossed finishes to enhance design variety and scratch resistance. The tanning processes for shoemaking favor tougher, more water-resistant treatments, whereas bagmaking leather often emphasizes a balance between durability and visual elegance.

Common Leather Grades Used for Shoes and Bags

Full-grain leather is highly prized for both shoemaking and bagmaking due to its durability and natural texture, while top-grain leather offers a smoother, more refined finish favored in high-end footwear and luxury handbags. Corrected grain leather, often used in bags, compensates for imperfections and is less common in shoes requiring flexibility and breathability. Your choice of leather grade impacts the longevity and aesthetic appeal of both shoes and bags, making it essential to select a type tailored to the product's wear and style requirements.

Thickness and Durability: Shoe Leather vs Bag Leather

Shoe leather typically ranges from 2.0 to 3.5 mm in thickness, designed for high durability and resistance to wear and tear from constant flexing and impact. Bag leather varies from 1.5 to 3.0 mm, balancing durability with flexibility to accommodate different bag styles and weight capacities. Your choice between shoemaking and bagmaking leather should consider that shoe leather offers superior toughness, while bag leather provides more pliability for intricate designs.

Flexibility and Softness: Essential Qualities in Bagmaking Leather

Bagmaking leather requires superior flexibility and softness to ensure comfort and ease of use, qualities often less emphasized in shoemaking leather, which prioritizes durability and structure. While shoemaking leather tends to be stiffer to provide foot support and withstand wear, bagmaking leather must remain pliable to accommodate frequent handling and maintain aesthetic appeal. Your choice of leather for bags should focus on these essential properties to achieve the perfect balance between durability and tactile comfort.

Finish and Appearance: What Matters for Shoes and Bags

Shoe leather typically features a smooth, polished finish designed for durability and a sleek appearance, enhancing your footwear's resistance to scuffs and wear. Bagmaking leather often prioritizes texture and aesthetic variety, showcasing natural grain or nubuck finishes that highlight artisanal craftsmanship and style. Your choice depends on whether you value the refined shine essential for shoes or the rich, tactile character that defines quality handbags.

Popular Leather Types for Shoemaking

Popular leather types for shoemaking include full-grain leather, known for its durability and natural texture, and top-grain leather, which offers a smooth finish ideal for dress shoes. Horween Chromexcel and vegetable-tanned leathers are favored for their flexibility and ability to mold to your foot shape over time. These materials provide the strength and comfort necessary for long-lasting, high-quality footwear in various styles.

Popular Leather Types for Bagmaking

Full-grain leather and top-grain leather are popular choices for bagmaking due to their durability and attractive finish, while shoemaking leather often includes thicker, stiffer varieties such as vegetable-tanned leather and chrome-tanned leather for added structure and support. Your bagmaking projects benefit from softer, more pliable leathers like genuine leather and pebble grain that offer flexibility without sacrificing strength. Selecting the right leather type ensures longevity and enhances the aesthetic appeal of your bags compared to the more rigid leathers used in shoemaking.

Cost and Availability: Shoemaking vs Bagmaking Leather

Shoemaking leather typically costs more due to its higher durability, thickness, and specific tannage processes designed for footwear resilience. Bagmaking leather is often more readily available and comes in a wider variety of finishes and flexibility, catering to diverse fashion trends and styles. Your choice depends on budget constraints and the intended durability required for the finished product.

Choosing the Right Leather for Your Project

Choosing the right leather for your project depends on the specific demands of shoemaking or bagmaking, as each requires different material properties. Shoemaking leather typically requires thicker, more durable hides like full-grain or vegetable-tanned leather to withstand wear, moisture, and flexibility for comfort. Bagmaking leather often favors lighter, more supple options such as chrome-tanned or aniline leathers that offer enhanced aesthetics and ease of shaping while maintaining strength.

Shoemaking leather vs bagmaking leather Infographic

libmatt.com

libmatt.com