Sides cut refers to trimming the edges or lateral parts of a material, often to create straight or clean boundaries, while bends cut involves cutting along curved or angled lines to shape the material according to specific contours. Understanding the difference helps you choose the appropriate technique for precise fabrication and design in various projects.

Table of Comparison

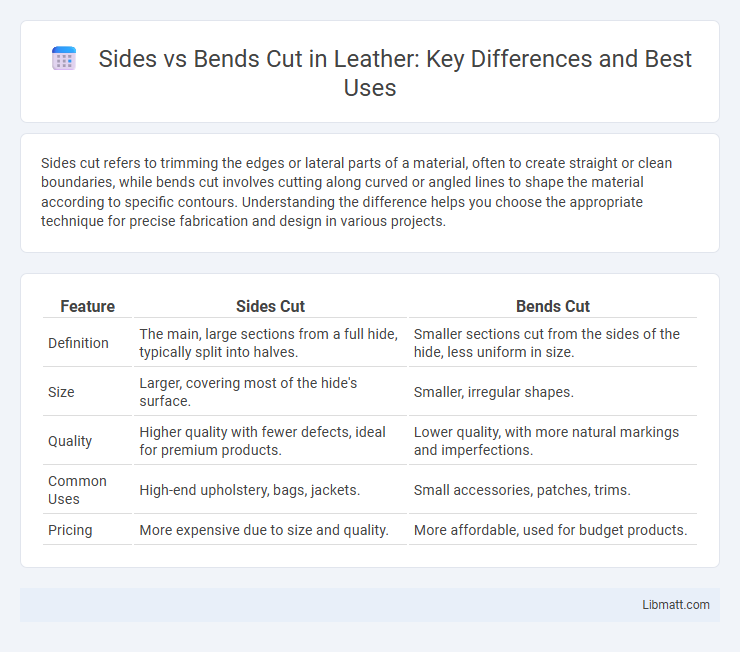

| Feature | Sides Cut | Bends Cut |

|---|---|---|

| Definition | The main, large sections from a full hide, typically split into halves. | Smaller sections cut from the sides of the hide, less uniform in size. |

| Size | Larger, covering most of the hide's surface. | Smaller, irregular shapes. |

| Quality | Higher quality with fewer defects, ideal for premium products. | Lower quality, with more natural markings and imperfections. |

| Common Uses | High-end upholstery, bags, jackets. | Small accessories, patches, trims. |

| Pricing | More expensive due to size and quality. | More affordable, used for budget products. |

Introduction to Sides Cut and Bends Cut

Sides Cut and Bends Cut are essential techniques in garment manufacturing that affect the structure and fit of clothing. Sides Cut refers to the straight or curved cuts along the side seams of a garment, shaping the overall silhouette, while Bends Cut focuses on cuts made at angles or curves to accommodate body movement and design details. Understanding these cuts enhances Your ability to create well-fitting and aesthetically pleasing apparel.

Definition of Sides Cut

Sides cut refers to a type of fabric cut where the material is sliced along the edges or sides, parallel to the grain of the fabric. This cutting method impacts the drape and stretch of the garment, often resulting in better structural stability compared to bias or bends cuts. Sides cut is commonly used in tailoring and fashion design to maintain the shape and fit of clothing items.

Definition of Bends Cut

Bends cut refers to the technique of cutting fabric along the curved contours or angles to accommodate the natural shape of the body or design element. It ensures smooth, precise edges that follow the fabric's bend, preventing distortion and maintaining the garment's intended fit and structure. This method differs from sides cut, which involves straight or slightly angled cuts primarily along the fabric's length for shaping purposes.

Key Differences Between Sides and Bends Cut

Sides cut refers to trimming the edges of a material to create straight, clean lines, while bends cut involves shaping the material by making precise angled cuts to facilitate folding or curvature. The key differences lie in the purpose and technique: sides cut ensures uniform dimensional accuracy along the edges, whereas bends cut is essential for achieving structural flexibility and design complexity. Your choice between sides and bends cut depends on whether your project requires rigid flat surfaces or dynamic, contoured shapes.

Applications of Sides Cut in Industry

Sides cut is widely used in industries such as metal fabrication, shipbuilding, and aerospace for creating precise straight edges and angles on sheet metal and structural components. This cutting technique ensures clean, accurate outlines essential for assembling parts with tight tolerances and maintaining structural integrity. Your production process benefits from sides cut by enhancing fit and finish, reducing material wastage, and improving overall efficiency in manufacturing complex assemblies.

Applications of Bends Cut in Industry

Bends cut is essential in industries such as metal fabrication, automotive manufacturing, and construction for shaping sheet metal and tubes into precise angles without compromising material integrity. This cutting technique enhances structural strength and accuracy in components like pipes, ductwork, and chassis frames. Your projects benefit from bends cut by ensuring smooth bends that reduce stress concentrations and improve overall product durability.

Advantages of Sides Cut

Sides cut offers precise alignment and cleaner edges, enhancing the aesthetic appeal and structural integrity of materials. This method reduces material waste by maximizing usable surface area, making it cost-effective for manufacturing and construction projects. Improved fit and finish from sides cut also streamline assembly processes, increasing overall production efficiency.

Advantages of Bends Cut

Bends cut offers superior structural integrity by preserving the continuous grain of the material, enhancing durability and strength in construction projects. This method reduces the risk of fractures and warping compared to sides cut, ensuring longer-lasting performance and stability. Choosing bends cut can optimize your design's resilience, particularly in applications requiring high load-bearing capacity.

Choosing Between Sides Cut and Bends Cut

Choosing between sides cut and bends cut depends on your specific fabrication needs and the geometry of the material. Sides cut typically involves straight-line cuts along the edges, ideal for creating sharp, clean profiles, while bends cut accommodates angled or curved shapes, essential for metal parts requiring precise deformation. Evaluating the design complexity and required accuracy will help determine which method ensures optimal strength and fit for your project.

Summary and Best Practices

Sides cuts create straight, clean edges on material, ideal for precise dimensions and smooth finishes, while bends cuts form curves or angles, perfect for shaping and structural integrity. Best practices for sides cuts include using sharp blades and steady pressure to ensure accuracy, whereas bends cuts require controlled scoring and gradual folding to prevent cracks or breaks. Choosing the appropriate cut type and technique enhances durability and meets design specifications efficiently.

Sides vs bends cut Infographic

libmatt.com

libmatt.com