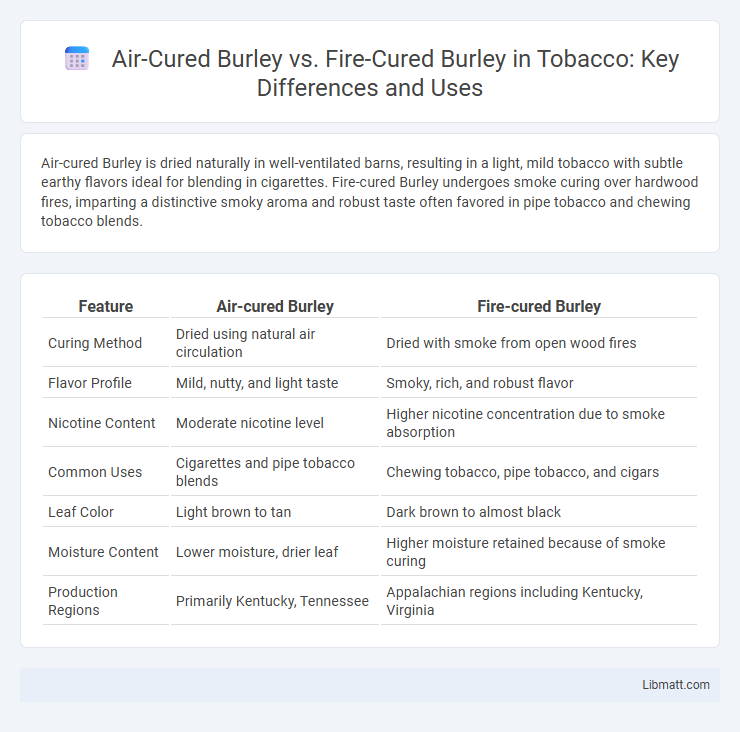

Air-cured Burley is dried naturally in well-ventilated barns, resulting in a light, mild tobacco with subtle earthy flavors ideal for blending in cigarettes. Fire-cured Burley undergoes smoke curing over hardwood fires, imparting a distinctive smoky aroma and robust taste often favored in pipe tobacco and chewing tobacco blends.

Table of Comparison

| Feature | Air-cured Burley | Fire-cured Burley |

|---|---|---|

| Curing Method | Dried using natural air circulation | Dried with smoke from open wood fires |

| Flavor Profile | Mild, nutty, and light taste | Smoky, rich, and robust flavor |

| Nicotine Content | Moderate nicotine level | Higher nicotine concentration due to smoke absorption |

| Common Uses | Cigarettes and pipe tobacco blends | Chewing tobacco, pipe tobacco, and cigars |

| Leaf Color | Light brown to tan | Dark brown to almost black |

| Moisture Content | Lower moisture, drier leaf | Higher moisture retained because of smoke curing |

| Production Regions | Primarily Kentucky, Tennessee | Appalachian regions including Kentucky, Virginia |

Introduction to Burley Tobacco

Burley tobacco is a light air-cured tobacco primarily grown in the United States, known for its low sugar content and mild flavor profile, making it a popular choice for cigarette blends and chewing tobacco. Air-cured Burley is dried naturally by hanging in well-ventilated barns, preserving its light color and maintaining a mellow taste. Fire-cured Burley tobacco undergoes curing over open fires using hardwood smoke, imparting a stronger, smoky flavor commonly used in pipe tobacco and certain chewing tobacco varieties.

Understanding Air-Curing Methods

Air-cured Burley tobacco undergoes a natural drying process in well-ventilated barns, allowing the leaves to cure slowly with air circulation that preserves their mild flavor and light brown color. Fire-cured Burley, in contrast, involves exposure to hardwood smoke during curing, which imparts a smoky aroma and robust taste, commonly used in pipe and chewing tobacco. Understanding these curing methods helps you select the right Burley tobacco based on desired flavor profiles and usage preferences.

Exploring Fire-Curing Techniques

Fire-curing techniques for Burley tobacco involve exposing the leaves to smoke from smoldering hardwoods, imparting a distinct smoky flavor and darkening the leaf color compared to air-cured Burley, which is dried naturally without smoke. This process enhances the tobacco's aroma and taste, making fire-cured Burley popular in pipe tobacco blends and certain cigar wrappers. Fire-curing requires controlled humidity and temperature to ensure even smoke absorption while preventing leaf damage, distinguishing it from the slower, more natural drying of air-curing.

Key Differences in the Curing Process

Air-cured Burley tobacco is dried naturally in ventilated barns, preserving a light, mild flavor due to the gradual moisture removal. Fire-cured Burley undergoes a curing process with controlled exposure to smoke from hardwood fires, infusing a smoky, robust flavor profile. The main distinction lies in air-cured Burley's reliance on ambient airflow versus fire-cured's deliberate smoke influence, impacting aroma and taste significantly.

Impact on Flavor and Aroma Profiles

Air-cured Burley tobacco develops a mild, light, and slightly sweet flavor profile due to natural drying methods that preserve subtle aromatic compounds. Fire-cured Burley, exposed to hardwood smoke during curing, gains a robust, smoky, and earthy aroma that significantly intensifies its flavor complexity. The contrast between these curing techniques results in distinct sensory experiences, where air-cured offers smoothness and fire-cured delivers boldness in tobacco products.

Chemical Composition Variations

Air-cured Burley tobacco typically exhibits higher sugar content and lower nicotine levels compared to fire-cured Burley, which undergoes a curing process involving smoke that increases phenolic compounds and certain alkaloids. The air-curing method leads to a milder chemical profile with reduced nitrogen content, while fire-curing introduces smoky phenols, resulting in a richer, more robust flavor profile with higher concentrations of volatile organic compounds. These chemical composition variations directly impact the aroma, taste, and harshness of the tobacco, influencing its suitability for different types of tobacco products.

Color and Texture Comparison

Air-cured Burley tobacco typically exhibits a lighter, tan to medium brown color with a soft, pliable texture, making it ideal for blending in cigarette and pipe tobacco. Fire-cured Burley, on the other hand, displays a darker, richer brown hue with a slightly rougher and firmer texture due to the smoke exposure during curing. Your choice between the two will depend on the desired flavor profile and visual appeal in the final product.

Popular Uses in Tobacco Products

Air-cured Burley tobacco is predominantly used in cigarettes and chewing tobacco due to its mild flavor and low sugar content, providing a smooth smoking experience. Fire-cured Burley tobacco, characterized by its smoky aroma, is commonly found in pipe tobacco, cigars, and certain chewing tobaccos, offering a robust and distinctive taste. Both varieties play crucial roles in blending processes to achieve specific flavor profiles in various tobacco products.

Health and Safety Considerations

Air-cured Burley tobacco undergoes a natural drying process that reduces exposure to harmful combustion byproducts, resulting in lower levels of carcinogenic polycyclic aromatic hydrocarbons (PAHs) compared to Fire-cured Burley. Fire-cured Burley involves direct exposure to smoke from smoldering hardwoods, increasing the presence of toxic compounds such as nicotine and formaldehyde, posing greater respiratory and cardiovascular risks for users. Understanding these health and safety differences is essential for consumers aiming to minimize harmful chemical intake linked to tobacco consumption.

Choosing Between Air-Cured and Fire-Cured Burley

Air-cured Burley offers a milder, sweeter flavor profile due to its natural drying process, making it ideal for blends requiring smoothness and subtlety. Fire-cured Burley develops a smoky, robust taste from exposure to smoke during curing, suitable for tobacco products that benefit from intense, hearty notes. Your choice depends on whether you prefer a gentle, earthy character with air-cured or a bold, smoky flavor with fire-cured Burley.

Air-cured Burley vs Fire-cured Burley Infographic

libmatt.com

libmatt.com