A solid plug offers maximum durability and strength, making it ideal for heavy-duty applications where stability is crucial. Your choice between a solid plug and a hollow plug depends on the need for weight reduction, as hollow plugs provide lighter alternatives without compromising essential functionality.

Table of Comparison

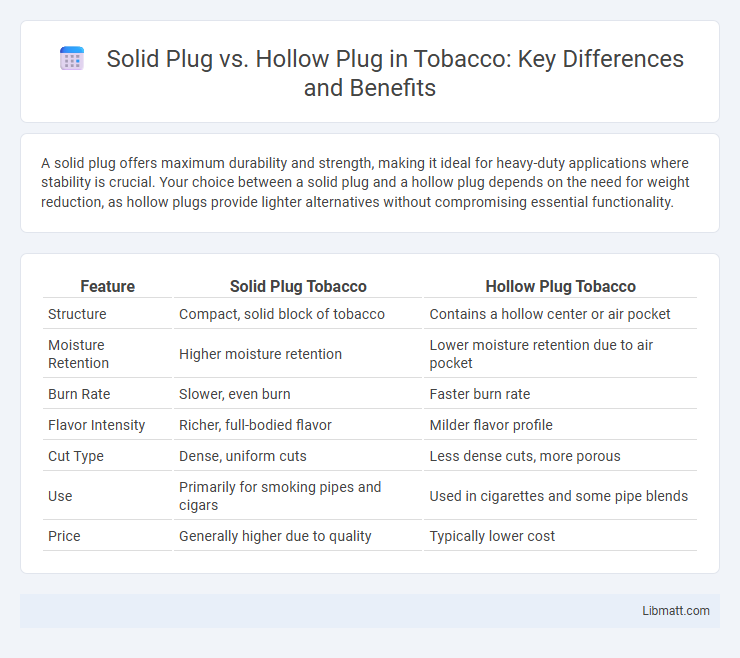

| Feature | Solid Plug Tobacco | Hollow Plug Tobacco |

|---|---|---|

| Structure | Compact, solid block of tobacco | Contains a hollow center or air pocket |

| Moisture Retention | Higher moisture retention | Lower moisture retention due to air pocket |

| Burn Rate | Slower, even burn | Faster burn rate |

| Flavor Intensity | Richer, full-bodied flavor | Milder flavor profile |

| Cut Type | Dense, uniform cuts | Less dense cuts, more porous |

| Use | Primarily for smoking pipes and cigars | Used in cigarettes and some pipe blends |

| Price | Generally higher due to quality | Typically lower cost |

Introduction to Solid and Hollow Plugs

Solid plugs provide maximum strength and durability due to their completely filled structure, making them ideal for high-pressure applications. Hollow plugs are lighter and allow for fluid or gas passage, offering reduced weight and material costs while maintaining sufficient stability for less demanding environments. Choosing between solid and hollow plugs depends on Your specific load requirements and operational conditions.

Definition and Basic Differences

A solid plug consists of a single, dense piece of material, providing maximum strength and durability, commonly used in heavy-duty applications requiring robust sealing. A hollow plug, on the other hand, features a cavity or hollow center, reducing weight and allowing for fluid passage or pressure equalization in certain mechanical or hydraulic systems. The primary difference lies in their structure: solid plugs offer superior mechanical integrity, while hollow plugs enable fluid dynamics or lighter weight requirements.

Material Composition: Solid vs Hollow Plugs

Solid plugs consist entirely of a uniform material, typically metals like stainless steel or brass, offering enhanced strength and durability for high-pressure applications. Hollow plugs have a cavity within, often made from the same external metal but designed to reduce weight and material costs while maintaining adequate sealing performance. The choice between solid and hollow plugs depends on application requirements, balancing factors like pressure tolerances, weight constraints, and corrosion resistance.

Strength and Durability Comparison

Solid plugs offer superior strength and durability due to their uniform material composition, making them ideal for high-stress applications where resistance to wear and impact is critical. Hollow plugs, while lighter and easier to install, may experience reduced mechanical strength and are more susceptible to deformation under heavy loads. Your choice between solid and hollow plugs should consider the required load-bearing capacity and long-term durability needs of your project.

Weight Considerations: Solid vs Hollow

Solid plugs are significantly heavier than hollow plugs due to their dense material composition, impacting overall equipment weight and ease of handling. Hollow plugs reduce weight without compromising sealing performance, making them ideal for applications requiring lighter components or frequent installation and removal. Weight savings with hollow plugs contribute to improved efficiency in transport and reduced stress on mechanical systems.

Installation Methods and Requirements

Solid plugs require straightforward installation methods, typically involving threading or driving them into pre-drilled holes to create a secure seal in solid materials. Hollow plugs demand more precise installation techniques, such as applying adhesives or using expansion mechanisms, to accommodate their cavity and ensure tight sealing. Installation requirements for solid plugs emphasize robust physical fit, while hollow plugs necessitate careful alignment and sealing procedures to prevent leaks or movement.

Common Applications for Each Type

Solid plugs are commonly used in high-pressure and high-temperature environments such as hydraulic systems, steam lines, and industrial piping where durability and leak resistance are critical. Hollow plugs, on the other hand, are typically employed in applications requiring fluid or gas flow monitoring, sensor insertion, or pressure relief, including HVAC systems and process control equipment. Your choice between solid and hollow plugs depends on whether you prioritize structural strength or functional access for instrumentation.

Cost Analysis: Which is More Economical?

Solid plugs generally cost more upfront due to the increased amount of raw material required, making them pricier than hollow plugs. However, hollow plugs can be more economical for applications where weight reduction and material savings are critical, as they use less material without compromising basic functionality. When considering Your overall investment, factor in long-term durability and maintenance costs, as solid plugs often provide greater strength and longevity, potentially lowering lifetime expenses.

Pros and Cons of Solid Plugs

Solid plugs offer superior durability and strength due to their continuous material structure, making them ideal for high-pressure and high-temperature applications. They provide better sealing performance and are less prone to deformation or leakage compared to hollow plugs. However, solid plugs are heavier, more expensive, and can be more difficult to install or remove in confined spaces.

Pros and Cons of Hollow Plugs

Hollow plugs offer reduced weight and easier handling compared to solid plugs, making them ideal for applications where weight savings are critical. However, hollow plugs may lack the same structural strength and durability as solid plugs, increasing the risk of deformation or failure under high pressure or heavy loads. Your choice depends on balancing these trade-offs between strength requirements and the need for lightweight components.

solid plug vs hollow plug Infographic

libmatt.com

libmatt.com