Air-cured tobacco undergoes a slow drying process in well-ventilated barns, preserving its natural sugars and yielding a mild, aromatic flavor ideal for cigars and pipe tobacco. Sun-cured tobacco dries quickly under direct sunlight, resulting in a stronger, more robust taste often preferred in traditional Asian cigarettes and certain chewing tobacco blends.

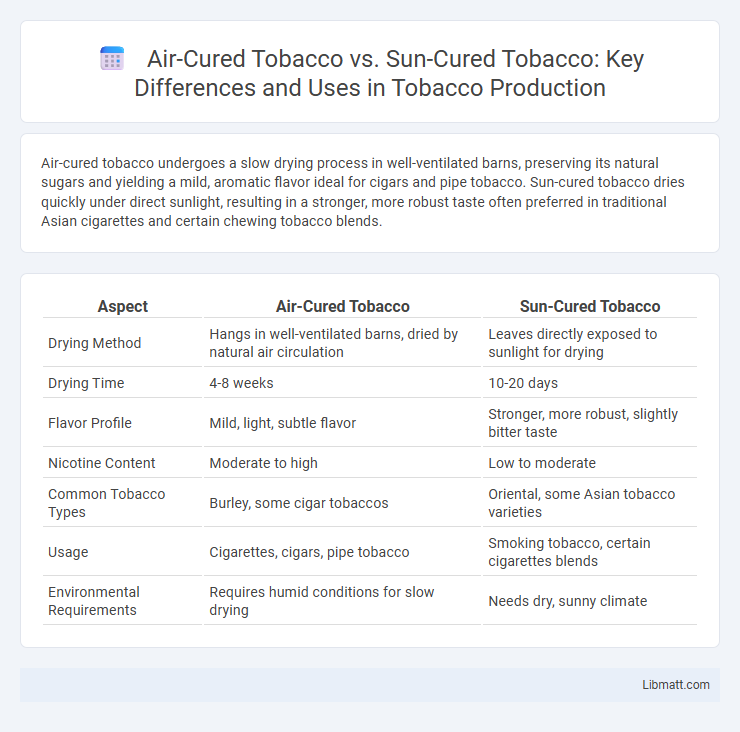

Table of Comparison

| Aspect | Air-Cured Tobacco | Sun-Cured Tobacco |

|---|---|---|

| Drying Method | Hangs in well-ventilated barns, dried by natural air circulation | Leaves directly exposed to sunlight for drying |

| Drying Time | 4-8 weeks | 10-20 days |

| Flavor Profile | Mild, light, subtle flavor | Stronger, more robust, slightly bitter taste |

| Nicotine Content | Moderate to high | Low to moderate |

| Common Tobacco Types | Burley, some cigar tobaccos | Oriental, some Asian tobacco varieties |

| Usage | Cigarettes, cigars, pipe tobacco | Smoking tobacco, certain cigarettes blends |

| Environmental Requirements | Requires humid conditions for slow drying | Needs dry, sunny climate |

Overview of Air-Cured and Sun-Cured Tobacco

Air-cured tobacco undergoes a drying process in well-ventilated barns where tobacco leaves are hung and naturally cured by air circulation, preserving a mild flavor and lower sugar content, commonly used in cigars and pipe tobacco. Sun-cured tobacco is dried directly under sunlight, accelerating the curing process and producing leaves with higher sugar and nicotine concentrations, often utilized in oriental and certain cigarette tobacco blends. The choice between air-cured and sun-cured methods significantly impacts the tobacco's chemical composition, flavor profile, and final use in tobacco products.

Definition and Key Characteristics of Air-Cured Tobacco

Air-cured tobacco is dried slowly through natural air exposure in well-ventilated barns, resulting in leaves that are light to dark brown with a mild flavor and low sugar content. This curing method preserves nicotine levels and produces a smooth, mellow tobacco often used in cigars, pipe tobacco, and snuff. Unlike sun-cured tobacco, which dries quickly under direct sunlight and yields a harsher, more acidic leaf, air-cured tobacco offers a balanced aroma and texture preferred for premium tobacco products.

Definition and Key Characteristics of Sun-Cured Tobacco

Sun-cured tobacco refers to tobacco leaves that dry naturally under direct sunlight, resulting in a slower curing process that enhances sugar content and imparts a rich, sweet flavor ideal for certain traditional cigars and oriental tobacco varieties. This method produces leaves with a distinctive golden-brown hue and a more aromatic profile compared to air-cured tobacco, which dries in shaded, ventilated barns. Understanding the unique characteristics of sun-cured tobacco can help you choose the best type for your smoking preferences or cultivation goals.

Regions Where Air-Cured Tobacco Is Commonly Produced

Air-cured tobacco is predominantly produced in regions such as the United States, especially in Kentucky and Tennessee, as well as parts of Italy, Serbia, and India. These areas provide the ideal climate with ample air circulation and moderate humidity necessary for the slow drying process that enhances the tobacco's flavor and aroma. The controlled environment during air-curing allows the tobacco leaves to develop a rich, mild taste favored in cigar and pipe tobacco production.

Regions Where Sun-Cured Tobacco Is Commonly Produced

Sun-cured tobacco is predominantly produced in Mediterranean regions, including countries like Turkey, Italy, and Greece, where the climate supports the drying process under direct sunlight. This method is also common in parts of China and Southeast Asia, where ample sun exposure accelerates the curing phase. The sun-curing technique enhances the tobacco's flavor by preserving its natural sugars and aromatic oils, making it distinct from air-cured varieties typically found in the United States and parts of Europe.

Curing Processes: Air-Curing vs Sun-Curing

Air-cured tobacco undergoes a slow drying process in well-ventilated barns, allowing natural air circulation to reduce moisture content over weeks, preserving the leaf's texture and enhancing its mild flavor profile. In contrast, sun-cured tobacco is dried directly under the sun, which rapidly decreases moisture while intensifying the sugar content and producing a stronger, sweeter taste often used in oriental tobacco varieties. The curing environment and duration significantly impact the chemical composition and quality of the tobacco, influencing its suitability for different tobacco products like cigars, cigarettes, or chewing tobacco.

Flavor Profile Differences Between Air-Cured and Sun-Cured Tobacco

Air-cured tobacco develops a rich, mellow flavor with earthy and nutty undertones due to its slow drying process in well-ventilated barns. Sun-cured tobacco, exposed directly to sunlight, produces a harsher, more robust taste with pronounced sweetness and a slightly smoky aroma. The flavor profile differences stem primarily from the curing environment, impacting the chemical composition and nicotine content in both types of tobacco.

Chemical Composition and Nicotine Content Comparison

Air-cured tobacco undergoes a slow drying process that preserves higher levels of sugars and results in lower nicotine content compared to sun-cured tobacco, which is rapidly dried under direct sunlight leading to a higher concentration of nicotine and reduced sugar levels. The chemical composition of air-cured tobacco typically features elevated levels of alkaloids and chlorogenic acids, contributing to smoother flavor profiles. In contrast, sun-cured tobacco contains increased amounts of nitrogenous compounds and nicotine, enhancing its harshness and potency.

Popular Uses and Tobacco Products for Each Method

Air-cured tobacco is primarily used in pipe tobacco, cigars, and certain chewing tobaccos, valued for its low sugar content and mild flavor profile that enhances smoke quality. Sun-cured tobacco, often associated with oriental tobacco varieties, is widely favored in cigarette blends for its aromatic and spicy qualities that contribute to the distinct taste of many popular cigarette brands. Understanding the differences in curing methods can help you select tobacco products that match your flavor preferences and desired smoking experience.

Environmental Impact and Sustainability Factors

Air-cured tobacco requires less energy input, relying on natural airflow for drying, which reduces its carbon footprint compared to sun-cured tobacco, typically dried outdoors using solar radiation. Sun-cured tobacco depends heavily on consistent sunlight, making it vulnerable to climate variability and potentially leading to uneven curing that wastes resources. Your choice between these methods can influence environmental sustainability, with air-curing generally favored for minimizing energy consumption and preserving ecosystem balance.

Air-cured tobacco vs Sun-cured tobacco Infographic

libmatt.com

libmatt.com