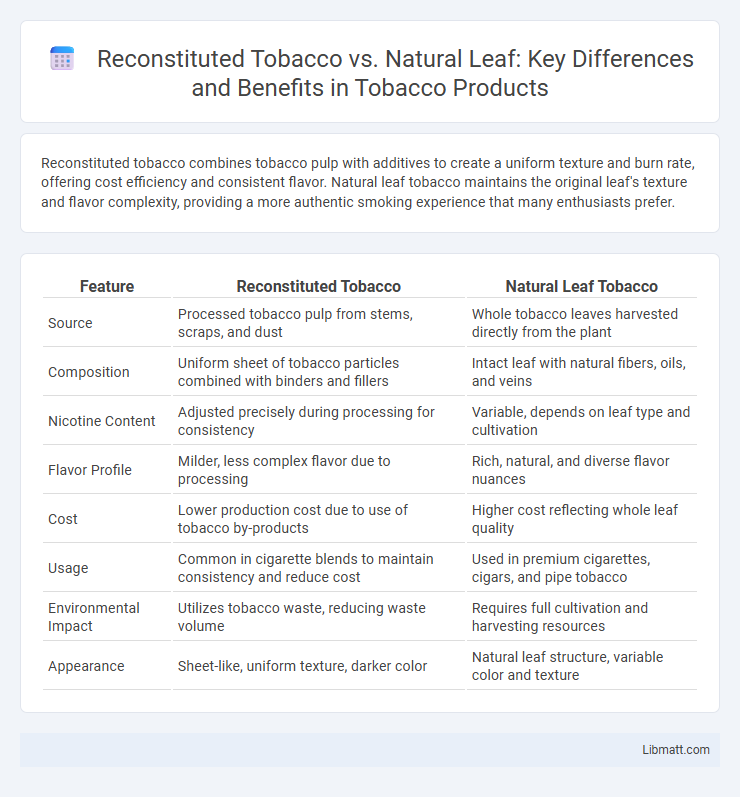

Reconstituted tobacco combines tobacco pulp with additives to create a uniform texture and burn rate, offering cost efficiency and consistent flavor. Natural leaf tobacco maintains the original leaf's texture and flavor complexity, providing a more authentic smoking experience that many enthusiasts prefer.

Table of Comparison

| Feature | Reconstituted Tobacco | Natural Leaf Tobacco |

|---|---|---|

| Source | Processed tobacco pulp from stems, scraps, and dust | Whole tobacco leaves harvested directly from the plant |

| Composition | Uniform sheet of tobacco particles combined with binders and fillers | Intact leaf with natural fibers, oils, and veins |

| Nicotine Content | Adjusted precisely during processing for consistency | Variable, depends on leaf type and cultivation |

| Flavor Profile | Milder, less complex flavor due to processing | Rich, natural, and diverse flavor nuances |

| Cost | Lower production cost due to use of tobacco by-products | Higher cost reflecting whole leaf quality |

| Usage | Common in cigarette blends to maintain consistency and reduce cost | Used in premium cigarettes, cigars, and pipe tobacco |

| Environmental Impact | Utilizes tobacco waste, reducing waste volume | Requires full cultivation and harvesting resources |

| Appearance | Sheet-like, uniform texture, darker color | Natural leaf structure, variable color and texture |

Introduction to Reconstituted Tobacco and Natural Leaf

Reconstituted tobacco is a processed product made by blending tobacco leaf scraps, stems, and dust into a uniform sheet, enhancing consistency and combustion in cigarette manufacturing. Natural leaf tobacco consists of whole, unprocessed tobacco leaves, valued for their traditional flavor and distinct aromatic qualities. The choice between reconstituted tobacco and natural leaf impacts the texture, burn rate, and flavor profile of tobacco products.

Composition and Processing Methods

Reconstituted tobacco is made by combining tobacco fibers, stems, dust, and fillers that are reprocessed into sheets using adhesives and additives, whereas natural leaf consists of whole tobacco leaves harvested and cured without significant alteration. The processing of reconstituted tobacco involves pulping and treating tobacco residues to create a uniform matrix, enhancing combustion and reducing waste, while natural leaf undergoes drying, aging, and curing to develop flavor and aroma. Differences in composition and processing impact the chemical consistency, burn rate, and overall tobacco product quality.

Flavor Profiles and Sensory Differences

Reconstituted tobacco offers a more uniform and mild flavor profile, often with less complexity compared to natural leaf tobacco, which provides rich, varied, and robust sensory experiences due to its intact leaf structure. The natural leaf's diverse chemical compounds enhance aroma and taste nuances, contributing to a fuller body and smoother smoke. Sensory differences arise because reconstituted tobacco blends leaf stems, dust, and small scraps, resulting in a consistent but less dynamic flavor compared to the vibrant and textured character of whole natural tobacco leaves.

Cost and Economic Considerations

Reconstituted tobacco offers a cost-effective alternative to natural leaf by utilizing tobacco scraps and dust, reducing raw material waste and lowering production expenses. Its consistent quality and easier blending can further streamline manufacturing processes, leading to economic efficiency for tobacco companies. Your choice between reconstituted and natural leaf should consider these cost benefits alongside desired product characteristics.

Health and Safety Implications

Reconstituted tobacco contains higher levels of certain harmful additives and chemicals compared to natural leaf tobacco, potentially increasing health risks for smokers. Studies suggest that the combustion of reconstituted tobacco may produce more toxicants such as ammonia and formaldehyde, which contribute to respiratory and cardiovascular diseases. Natural leaf tobacco generally contains fewer processing chemicals, but both types pose significant health hazards due to nicotine and tar exposure.

Environmental Impact

Reconstituted tobacco significantly reduces environmental impact by utilizing tobacco scraps and stems, minimizing agricultural waste compared to natural leaf tobacco, which requires extensive farming and land use. The production of reconstituted tobacco typically demands less water and energy, lowering its carbon footprint relative to traditional tobacco cultivation. Despite these advantages, concerns remain about the chemical processing involved in reconstituted tobacco, which can contribute to environmental pollution if not managed properly.

Regulatory Standards and Compliance

Reconstituted tobacco offers manufacturers greater control over regulatory standards and compliance due to its consistent composition and reduced levels of harmful constituents compared to natural leaf tobacco. Regulatory agencies often scrutinize additives and processing methods in reconstituted tobacco to ensure safety and adherence to labeling laws, which can streamline approval processes. Understanding these compliance distinctions helps you make informed decisions about product development and market entry strategies.

Popular Brands and Product Types

Popular brands like Marlboro and Camel incorporate reconstituted tobacco in products such as cigarettes and cigars to balance flavor and enhance burn quality. Natural leaf tobacco remains predominant in premium cigars and pipe tobacco, prized for its robust and authentic taste. Your choice between reconstituted tobacco and natural leaf often depends on preferred product types and flavor profiles.

Consumer Preferences and Market Trends

Consumer preferences are increasingly leaning toward natural leaf tobacco due to its perceived higher quality and authentic flavor, driving market trends favoring traditional products. However, reconstituted tobacco remains popular in low-cost and machine-rolled cigarettes for its consistency and cost-efficiency, appealing to value-conscious consumers. Understanding your target audience's priorities is crucial, as demand for natural leaf is growing in premium segments while reconstituted blends retain a significant share in mass-market offerings.

Future Developments in Tobacco Manufacturing

Future developments in tobacco manufacturing emphasize sustainability and efficiency, with reconstituted tobacco playing a crucial role in reducing waste by utilizing tobacco scraps and stems. Innovations aim to improve the consistency, flavor, and chemical composition of reconstituted tobacco, making it comparable to natural leaf options. Your smoking experience will benefit from these advancements as manufacturers refine blending techniques and introduce enhanced formulations to meet evolving regulatory and consumer demands.

Reconstituted tobacco vs natural leaf Infographic

libmatt.com

libmatt.com