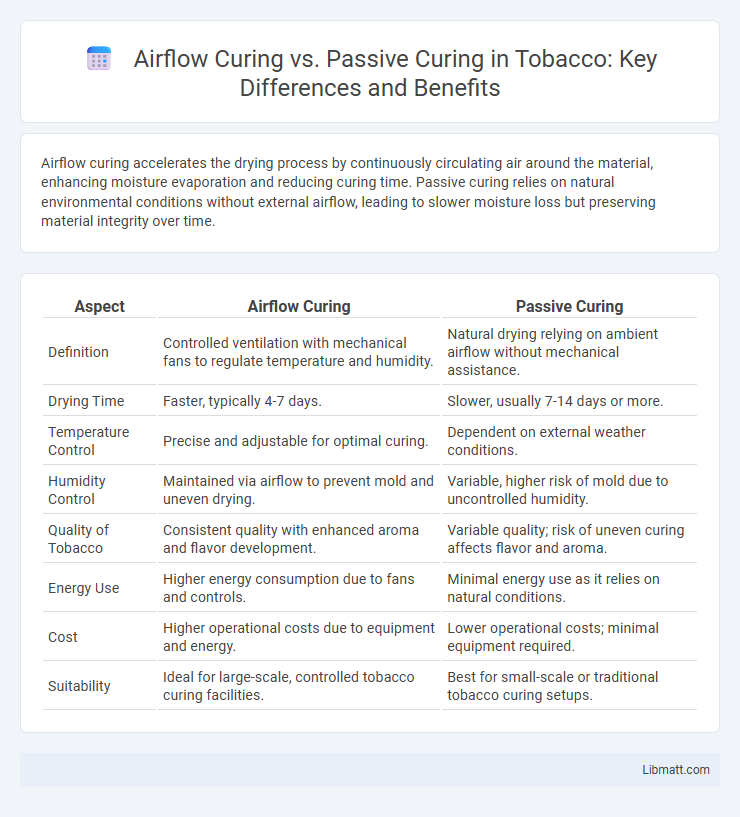

Airflow curing accelerates the drying process by continuously circulating air around the material, enhancing moisture evaporation and reducing curing time. Passive curing relies on natural environmental conditions without external airflow, leading to slower moisture loss but preserving material integrity over time.

Table of Comparison

| Aspect | Airflow Curing | Passive Curing |

|---|---|---|

| Definition | Controlled ventilation with mechanical fans to regulate temperature and humidity. | Natural drying relying on ambient airflow without mechanical assistance. |

| Drying Time | Faster, typically 4-7 days. | Slower, usually 7-14 days or more. |

| Temperature Control | Precise and adjustable for optimal curing. | Dependent on external weather conditions. |

| Humidity Control | Maintained via airflow to prevent mold and uneven drying. | Variable, higher risk of mold due to uncontrolled humidity. |

| Quality of Tobacco | Consistent quality with enhanced aroma and flavor development. | Variable quality; risk of uneven curing affects flavor and aroma. |

| Energy Use | Higher energy consumption due to fans and controls. | Minimal energy use as it relies on natural conditions. |

| Cost | Higher operational costs due to equipment and energy. | Lower operational costs; minimal equipment required. |

| Suitability | Ideal for large-scale, controlled tobacco curing facilities. | Best for small-scale or traditional tobacco curing setups. |

Introduction to Curing Methods

Airflow curing and passive curing are essential techniques in concrete curing that significantly influence hydration and strength development. Airflow curing utilizes controlled aeration to regulate moisture evaporation and temperature, promoting uniform curing conditions and minimizing surface cracking. Passive curing relies on natural environmental factors, maintaining moisture through coverings or ambient humidity, which may lead to inconsistent curing and varied concrete durability.

What is Airflow Curing?

Airflow curing is a process that accelerates concrete hydration by maintaining continuous airflow around the surface, enhancing moisture retention and temperature control. This method improves strength development and reduces surface cracking compared to passive curing, which relies on natural environmental conditions without active intervention. Optimizing airflow during curing ensures uniform curing conditions and better durability of the concrete structure.

What is Passive Curing?

Passive curing refers to the natural process of maintaining adequate moisture and temperature in concrete without applying external force or heat. It relies on ambient conditions such as humidity and temperature to hydrate the cement, ensuring strength development and durability over time. Unlike Airflow curing, which uses controlled air circulation to accelerate drying and curing, passive curing depends primarily on environmental factors and surface coverings to retain moisture.

Key Differences Between Airflow and Passive Curing

Airflow curing enhances hydration by continuously supplying fresh air, accelerating strength development, while passive curing relies on natural moisture retention and ambient conditions to maintain concrete moisture. Airflow curing improves durability and reduces curing time thanks to controlled ventilation and temperature regulation, whereas passive curing may result in inconsistent strength and increased risk of surface cracking. The effectiveness of airflow curing depends on precise airflow rates and environmental control, contrasting with the simplicity and low cost but potentially variable results of passive curing methods.

Advantages of Airflow Curing

Airflow curing enhances concrete strength and durability by accelerating moisture evaporation and maintaining optimal curing conditions. This method reduces curing time compared to passive curing, leading to faster project completion and cost efficiency. Your construction process benefits from improved surface quality and reduced risk of cracking due to controlled airflow and temperature consistency.

Benefits of Passive Curing

Passive curing offers consistent moisture retention essential for optimal concrete strength development, reducing the risk of surface cracking and shrinkage. Unlike Airflow curing, it requires minimal equipment and energy, making it more cost-effective and environmentally friendly. Your concrete structure benefits from improved durability and enhanced long-term performance through this reliable curing method.

Limitations of Airflow Curing

Airflow curing, while effective in accelerating moisture evaporation and reducing drying time, faces limitations such as uneven curing caused by inconsistent airflow distribution, which can result in surface cracks or weakened material integrity. This method often requires precise control of airflow velocity and temperature to prevent rapid surface drying that leads to shrinkage stresses. In contrast, passive curing provides uniform moisture retention but at the expense of longer curing periods and lower early strength gain.

Drawbacks of Passive Curing

Passive curing often results in insufficient moisture retention, leading to incomplete hydration and reduced concrete strength. This method's reliance on ambient conditions increases the risk of surface cracking and durability issues over time. You may face compromised structural performance due to the uneven curing environment inherent in passive curing techniques.

Applications Best Suited for Each Method

Airflow curing is best suited for industrial applications requiring rapid drying of coatings, adhesives, or concrete where controlled temperature and airflow enhance curing speed and uniformity. Passive curing is ideal for construction projects involving concrete structures, such as pavements and slabs, where natural hydration occurs over time without mechanical intervention. Airflow curing benefits manufacturing settings demanding quick turnaround, while passive curing supports large-scale, outdoor infrastructure needing gradual moisture retention for optimal strength development.

Choosing Between Airflow and Passive Curing

Choosing between airflow curing and passive curing depends on factors like curing time, environmental control, and desired concrete strength. Airflow curing accelerates moisture evaporation with controlled ventilation, reducing drying time and improving surface hardness. Passive curing relies on natural ambient conditions, offering energy efficiency but often requiring longer curing periods to achieve optimal durability.

Airflow curing vs passive curing Infographic

libmatt.com

libmatt.com