High-density blending creates smooth, creamy textures by combining ingredients with minimal air, ideal for thick smoothies and purees. Low-density blending incorporates more air, resulting in lighter, fluffier mixtures perfect for frothy drinks and whipped recipes.

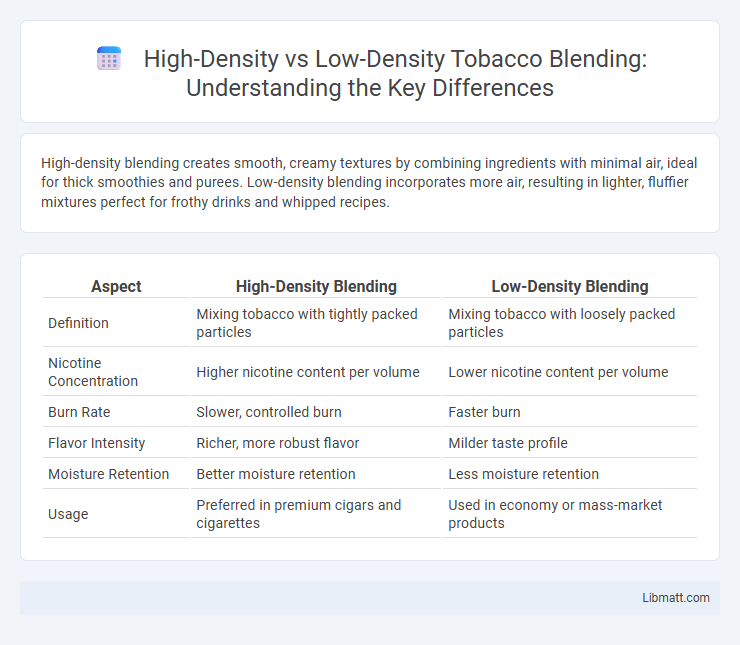

Table of Comparison

| Aspect | High-Density Blending | Low-Density Blending |

|---|---|---|

| Definition | Mixing tobacco with tightly packed particles | Mixing tobacco with loosely packed particles |

| Nicotine Concentration | Higher nicotine content per volume | Lower nicotine content per volume |

| Burn Rate | Slower, controlled burn | Faster burn |

| Flavor Intensity | Richer, more robust flavor | Milder taste profile |

| Moisture Retention | Better moisture retention | Less moisture retention |

| Usage | Preferred in premium cigars and cigarettes | Used in economy or mass-market products |

Understanding High-Density vs Low-Density Blending

High-density blending involves the combination of materials with closely packed particles, resulting in a uniform texture and enhanced structural integrity, commonly used in industries like pharmaceuticals and composites. Low-density blending features materials with larger particle sizes or more air spaces between particles, leading to lighter mixtures ideal for applications such as insulation or lightweight packaging. Understanding the differences in particle size, mixture uniformity, and final product density is crucial for optimizing manufacturing processes and achieving desired material properties.

Key Differences Between High-Density and Low-Density Blending

High-density blending involves tightly packed data points or components, resulting in smoother transitions and more precise outcomes, while low-density blending features loosely spaced elements, often leading to more noticeable gradients or separations. The key differences include processing speed, as high-density blending typically requires more computational power, and the level of detail, with high-density providing finer resolution compared to the coarse texture in low-density blending. Understanding these distinctions can help you optimize your blending techniques for applications like image processing, material synthesis, or audio mixing.

Material Compatibility in Blending Processes

High-density blending requires materials with similar melting points and viscosities to ensure uniform mixing and avoid phase separation. Low-density blending accommodates a wider range of material compatibilities, often suitable for combining polymers, additives, or fillers with varying thermal properties. Selecting the appropriate density blending process is critical for optimizing material compatibility and achieving desired product performance.

Equipment Used in High-Density and Low-Density Blending

High-density blending relies on equipment such as high-shear mixers, homogenizers, and extruders designed to handle viscous materials and ensure uniform particle distribution. Low-density blending commonly uses ribbon blenders, paddle mixers, and drum blenders optimized for powders and lightweight components to achieve consistent mixing without compressing the material. Your choice of blending equipment directly impacts product quality, processing time, and scalability in manufacturing operations.

Energy Consumption: High-Density vs Low-Density Blending

High-density blending typically consumes less energy compared to low-density blending due to reduced material volume and improved mixing efficiency, resulting in faster processing times. Low-density blending demands higher energy for agitation and movement of bulkier, less compact materials, increasing operational costs. Optimizing blend density directly impacts energy consumption by minimizing power requirements and enhancing thermal management during production.

Product Quality and Consistency Outcomes

High-density blending enhances product quality by ensuring uniform ingredient distribution, leading to consistent texture and flavor in every batch. Low-density blending may result in uneven mixing, causing variability in product performance and potential quality defects. Consistency in high-density blends supports better control over manufacturing processes, reducing waste and improving overall product reliability.

Application Areas for Each Blending Method

High-density blending is ideal for applications requiring uniform mixtures in industries like pharmaceuticals, chemicals, and food processing, where precise ingredient distribution is critical. Low-density blending suits sectors such as agriculture and construction for handling bulk materials like seeds or cement, emphasizing volume over homogeneity. Your choice depends on the required mixture consistency and the physical properties of the materials involved.

Efficiency and Throughput Comparisons

High-density blending offers greater efficiency by maximizing material volume within a smaller footprint, resulting in faster processing times and higher throughput compared to low-density blending. The compact arrangement in high-density systems reduces energy consumption and minimizes handling steps, enhancing overall operational performance. Your production line can achieve significant output improvements with high-density blending technology, especially in industries requiring rapid and consistent mixing.

Cost Implications of Blending Density Choices

High-density blending often incurs higher upfront costs due to increased material usage and more complex processing requirements compared to low-density blending. Low-density blending can reduce expenses by minimizing raw material consumption and energy use, making it ideal for budget-sensitive projects. Choosing the appropriate blending density directly impacts overall production costs, influencing profitability and resource allocation.

Choosing the Right Blending Density for Your Needs

High-density blending offers a more uniform mixture with fewer air pockets, ideal for applications requiring consistent texture and enhanced durability. Low-density blending, on the other hand, provides a lighter, more aerated product, suitable for applications where weight reduction and flexibility are priorities. Choosing the right blending density for your needs depends on balancing these factors with the specific performance and cost requirements of your project.

High-density blending vs low-density Infographic

libmatt.com

libmatt.com