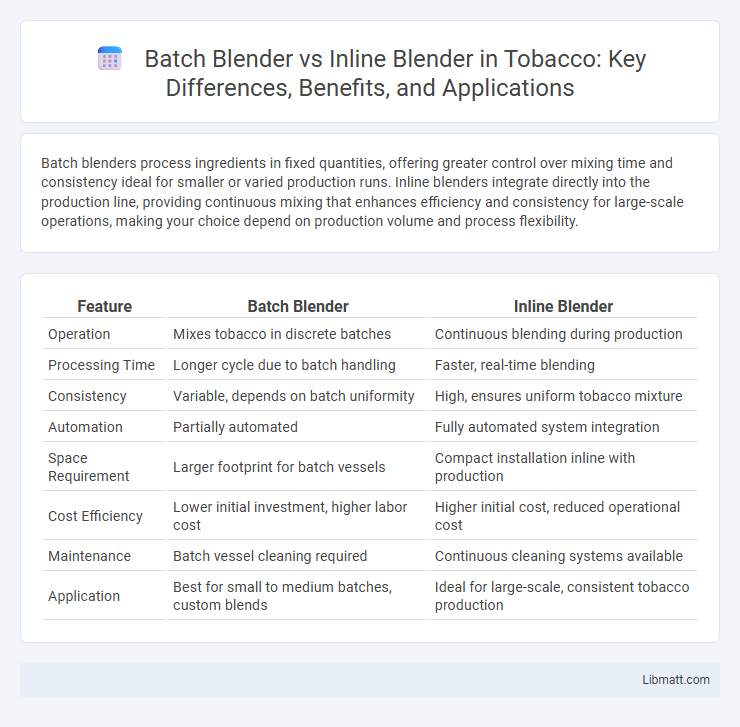

Batch blenders process ingredients in fixed quantities, offering greater control over mixing time and consistency ideal for smaller or varied production runs. Inline blenders integrate directly into the production line, providing continuous mixing that enhances efficiency and consistency for large-scale operations, making your choice depend on production volume and process flexibility.

Table of Comparison

| Feature | Batch Blender | Inline Blender |

|---|---|---|

| Operation | Mixes tobacco in discrete batches | Continuous blending during production |

| Processing Time | Longer cycle due to batch handling | Faster, real-time blending |

| Consistency | Variable, depends on batch uniformity | High, ensures uniform tobacco mixture |

| Automation | Partially automated | Fully automated system integration |

| Space Requirement | Larger footprint for batch vessels | Compact installation inline with production |

| Cost Efficiency | Lower initial investment, higher labor cost | Higher initial cost, reduced operational cost |

| Maintenance | Batch vessel cleaning required | Continuous cleaning systems available |

| Application | Best for small to medium batches, custom blends | Ideal for large-scale, consistent tobacco production |

Introduction to Batch and Inline Blenders

Batch blenders operate by mixing a fixed quantity of materials in a single vessel, ensuring thorough homogenization before discharge, making them ideal for small to medium production volumes. Inline blenders continuously blend materials during the flow process, allowing for real-time mixing and consistent product quality in high-volume industrial applications. The choice between batch and inline blenders depends on factors like production scale, material characteristics, and desired mixing precision.

Key Differences Between Batch and Inline Blending Systems

Batch blenders mix specific quantities of materials in discrete containers, allowing precise control over formulation and flexibility for multiple product variations, while inline blenders continuously combine ingredients during processing, ensuring consistent blending and high throughput. Batch blending systems are ideal for smaller volumes and varying recipes, whereas inline blenders suit large-scale production with steady flow rates and uniform output quality. Key differences include operational scale, process continuity, and adaptability to product changes, influencing equipment choice based on production requirements.

How Batch Blenders Work

Batch blenders mix ingredients by loading all components into a single container where they are blended together through mechanical agitation, ensuring uniform particle distribution in each batch. The process involves carefully timed mixing cycles to achieve consistent homogeneity, making batch blenders ideal for recipes requiring precise control over ingredient proportions. These systems allow for thorough cleaning between batches, reducing contamination risk and enhancing product quality in pharmaceutical and food industries.

Understanding Inline Blender Functionality

Inline blenders integrate directly into the production line, enabling continuous mixing of materials with precise control over blending time and intensity. This design minimizes contamination risk and reduces processing time compared to batch blenders, which operate in separate, enclosed vessels with intermittent mixing cycles. Understanding inline blender functionality is essential for industries requiring consistent homogeneity in high-throughput processes, such as pharmaceuticals, food processing, and chemical manufacturing.

Advantages of Batch Blenders

Batch blenders offer precise control over ingredient mixing, ensuring consistent and uniform blends crucial in pharmaceutical and food industries. Their flexibility allows handling varied batch sizes and complex formulations without cross-contamination risks, enhancing product quality. Maintenance and cleaning processes are simpler compared to inline blenders, reducing downtime and operational costs.

Benefits of Inline Blenders

Inline blenders offer continuous mixing, which enhances process efficiency and reduces downtime compared to batch blenders that operate in separate vessels. They provide consistent product quality through precise control of blending parameters, minimizing variations and improving uniformity. The compact design of inline blenders reduces footprint and energy consumption, making them ideal for high-volume production environments.

Application Scenarios: When to Use Batch vs Inline Blenders

Batch blenders are ideal for small to medium production volumes requiring high flexibility and easy cleaning, commonly used in pharmaceutical and food industries for precise ingredient mixing. Inline blenders suit continuous processing environments where consistent product quality and rapid blending are critical, often found in chemical manufacturing and large-scale cosmetics production. Choosing between batch and inline blenders depends on production scale, ingredient sensitivity, and process integration needs.

Cost Considerations: Batch Blenders vs Inline Blenders

Batch blenders typically require lower initial capital investment compared to inline blenders due to simpler design and smaller scale operation, making them cost-effective for small to medium production volumes. Inline blenders, while generally more expensive upfront, offer lower operational costs through continuous processing, reduced labor, and minimized downtime, which can lead to significant savings in high-volume manufacturing. Maintenance and energy expenses for inline blenders can be higher but are offset by increased efficiency and consistent product quality, impacting overall cost-effectiveness based on production needs.

Maintenance and Operational Efficiency Comparison

Batch blenders require periodic shutdowns for cleaning and maintenance, leading to longer downtime compared to inline blenders, which operate continuously with minimal intervention. Inline blenders offer higher operational efficiency by allowing seamless integration into production lines, reducing product waste and speeding up material processing. Maintenance costs for batch blenders tend to be higher due to their complex internal components and manual handling, while inline blenders benefit from automated cleaning cycles and fewer moving parts.

Choosing the Right Blender for Your Production Needs

Batch blenders offer precise control over small to medium-sized ingredient volumes, making them ideal for customizable, high-quality batches in diverse production environments. Inline blenders enable continuous, high-speed mixing directly in the production line, significantly improving efficiency for large-scale manufacturing processes. Your choice between these depends on the scale, flexibility, and consistency requirements of your specific production needs.

Batch blender vs inline blender Infographic

libmatt.com

libmatt.com