High moisture content in materials promotes bacterial growth and mold development, increasing the risk of spoilage and structural damage. Low moisture levels help preserve product quality and extend shelf life by inhibiting microbial activity and reducing the likelihood of degradation.

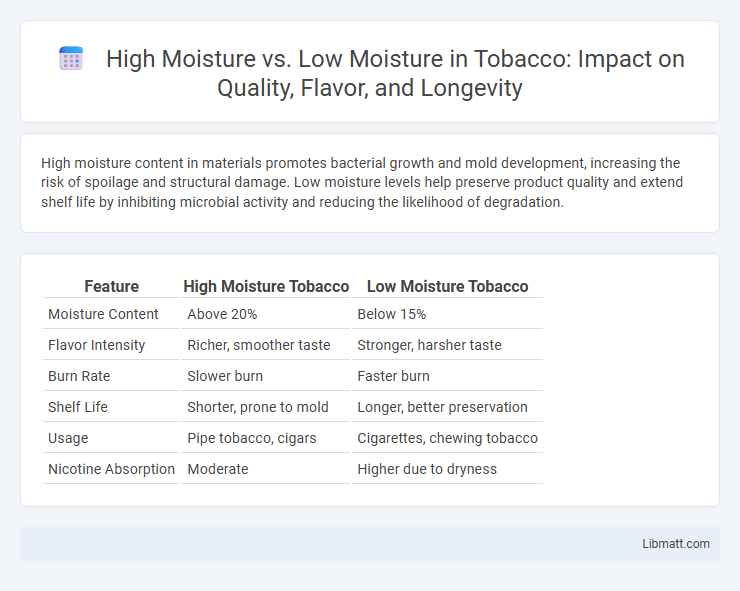

Table of Comparison

| Feature | High Moisture Tobacco | Low Moisture Tobacco |

|---|---|---|

| Moisture Content | Above 20% | Below 15% |

| Flavor Intensity | Richer, smoother taste | Stronger, harsher taste |

| Burn Rate | Slower burn | Faster burn |

| Shelf Life | Shorter, prone to mold | Longer, better preservation |

| Usage | Pipe tobacco, cigars | Cigarettes, chewing tobacco |

| Nicotine Absorption | Moderate | Higher due to dryness |

Understanding Moisture Content: High vs Low

High moisture content refers to a greater amount of water present in a substance, typically above 20-30%, while low moisture content indicates less water, often below 10-15%. In food products, high moisture levels can enhance texture and juiciness but reduce shelf life due to microbial growth, whereas low moisture extends preservation by inhibiting microbial activity. Accurate moisture measurement methods like Karl Fischer titration or moisture analyzers are essential for quality control and product stability.

The Science Behind Moisture Levels

Moisture levels significantly impact the physical and chemical properties of materials, influencing their texture, weight, preservation, and microbial growth. High moisture content promotes enzymatic activity and microbial proliferation, which can accelerate spoilage and degradation in food or organic materials, whereas low moisture inhibits these processes, enhancing shelf life and stability. Understanding the science behind moisture levels allows you to optimize storage conditions and product formulations for quality and safety.

Impact of Moisture on Product Quality

High moisture content in products accelerates microbial growth, leading to spoilage and reduced shelf life, especially in perishable goods like fruits and dairy. Low moisture levels inhibit microbial activity, preserving texture and flavor but may cause brittleness or dryness in products such as baked goods or snacks. Controlling moisture content is crucial for maintaining product quality, safety, and consumer satisfaction across the food industry.

High Moisture Benefits and Applications

High moisture content in materials enhances hydration, improves softness, and supports biological processes, making it ideal for applications in food preservation, agriculture, and cosmetics. Foods with high moisture maintain freshness and nutrient retention while promoting easier digestion and texture improvement. Your products benefit from increased shelf life and enhanced functionality when leveraging high moisture conditions.

Low Moisture Advantages and Uses

Low moisture content in food products enhances shelf life by reducing microbial growth and spoilage, making items like dried fruits, nuts, and powdered ingredients ideal for long-term storage. These foods maintain concentrated flavor and nutrients due to minimal water presence, supporting better preservation of taste and quality. Low moisture also facilitates easier transportation and packaging, reducing weight and bulk while maintaining product integrity.

Shelf Life: How Moisture Content Plays a Role

High moisture content in foods accelerates microbial growth, significantly reducing shelf life due to faster spoilage. Low moisture products typically have extended shelf life as reduced water availability inhibits bacterial and mold development. Understanding moisture levels helps you optimize storage conditions and prolong the freshness of your food.

Processing Techniques for Different Moisture Levels

Processing techniques for high moisture materials often involve dehydration methods such as drying, evaporation, or freeze-drying to reduce water content and prevent microbial growth. Low moisture processing emphasizes moisture retention and protection, utilizing vacuum sealing or modified atmosphere packaging to maintain product quality and extend shelf life. Selecting appropriate techniques depends on the initial moisture content, desired shelf stability, and end-use application to optimize product preservation and safety.

Safety and Preservation Considerations

High moisture content in food increases the risk of microbial growth, leading to faster spoilage and potential foodborne illnesses, necessitating refrigeration or preservatives to ensure safety. Low moisture foods have reduced water activity, inhibiting bacteria and mold growth, which extends shelf life and enhances preservation without refrigeration. Proper packaging and storage conditions further optimize safety and maintain quality by controlling moisture levels.

Industry Examples: Where Moisture Matters

In the food industry, high moisture content is essential for products like fresh fruits, vegetables, and dairy to maintain texture, flavor, and shelf life, while low moisture is critical in snacks, cereals, and powdered ingredients to prevent microbial growth and ensure longevity. In pharmaceuticals, low moisture environments are vital for the stability and shelf life of dry powders and tablets, whereas certain injectable solutions require controlled high moisture for efficacy. Electronics manufacturing demands stringent low moisture conditions during assembly to avoid corrosion and electrical failures, contrasting with the agricultural sector where high moisture levels are necessary for crop growth and soil health.

Choosing the Right Moisture Level for Your Needs

High moisture products provide enhanced hydration, making them ideal for dry or sensitive skin requiring deep nourishment. Low moisture options suit oily or combination skin types by reducing excess oil and preventing clogged pores. Your choice should align with your skin type and hydration needs to maintain optimal balance and comfort.

High moisture vs low moisture Infographic

libmatt.com

libmatt.com