Continuing curing allows for gradual polymerization, ensuring more uniform hardness and reduced internal stresses in dental restorations. Bulk curing speeds up the process by curing large volumes at once but may increase shrinkage and compromise the material's long-term durability.

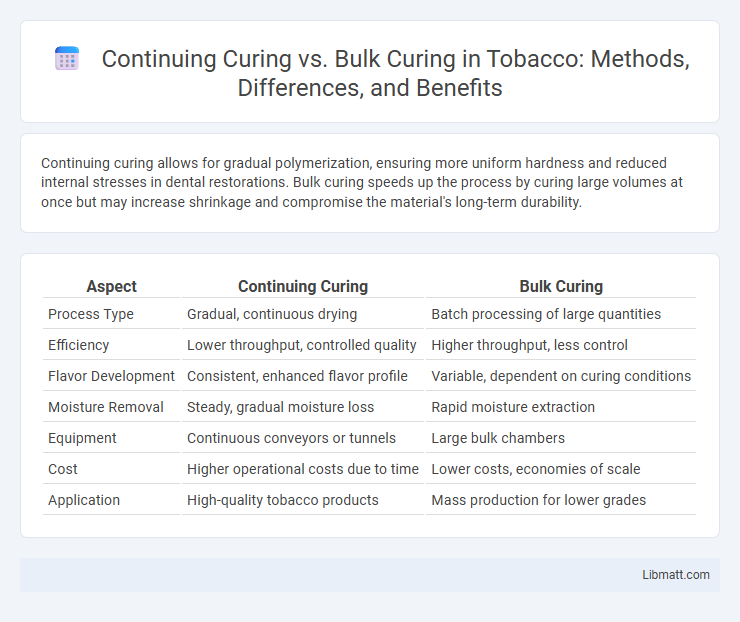

Table of Comparison

| Aspect | Continuing Curing | Bulk Curing |

|---|---|---|

| Process Type | Gradual, continuous drying | Batch processing of large quantities |

| Efficiency | Lower throughput, controlled quality | Higher throughput, less control |

| Flavor Development | Consistent, enhanced flavor profile | Variable, dependent on curing conditions |

| Moisture Removal | Steady, gradual moisture loss | Rapid moisture extraction |

| Equipment | Continuous conveyors or tunnels | Large bulk chambers |

| Cost | Higher operational costs due to time | Lower costs, economies of scale |

| Application | High-quality tobacco products | Mass production for lower grades |

Understanding Continuing Curing and Bulk Curing

Continuing curing involves applying multiple layers of resin or composite material incrementally, allowing each layer to polymerize thoroughly before the next application, which minimizes shrinkage and ensures optimal mechanical properties. Bulk curing, in contrast, entails curing a thick layer of material in a single step, offering faster application but risking incomplete polymerization and higher stress at the interface. Understanding these differences helps you choose the appropriate technique for durable and effective dental restorations.

Key Differences Between Continuing and Bulk Curing

Continuing curing involves gradually exposing the material to curing agents over an extended period, ensuring uniform polymerization and minimizing internal stresses. Bulk curing, in contrast, applies a single, intense curing process to the entire mass simultaneously, which can lead to uneven curing and higher risks of defects like cracking or incomplete polymerization. The key differences lie in curing time, temperature control, and the uniformity of the final material properties, with continuing curing offering better control and improved mechanical performance.

The Science Behind Each Curing Method

Continuing curing involves incremental light exposure that allows deeper polymerization and reduces shrinkage stress in resin composites, enhancing material longevity. Bulk curing utilizes a single, higher-intensity light exposure to cure larger volumes quickly but may risk incomplete polymerization in deeper layers, potentially compromising physical properties. Understanding the photopolymerization kinetics and light penetration depth is critical to optimizing the curing technique for dental restoratives.

Advantages of Continuing Curing

Continuing curing allows for enhanced control over polymerization, resulting in improved mechanical properties and reduced internal stresses in the final product. This method optimizes depth of cure and ensures consistent hardness throughout, minimizing defects associated with incomplete polymerization. Your materials benefit from increased durability and dimensional stability when continuing curing processes are applied effectively.

Benefits of Bulk Curing

Bulk curing offers significant benefits by allowing the polymerization of larger composite increments, reducing chair time and improving workflow efficiency in dental restorations. This technique enhances the degree of conversion throughout the material, resulting in better mechanical properties and long-term durability. Bulk curing minimizes shrinkage stress and potential gaps between layers, contributing to enhanced marginal integrity and clinical performance.

Common Applications in Industry

Continuing curing is commonly employed in industries requiring precise control over polymerization processes, such as aerospace composite manufacturing and electronics encapsulation, where layer-by-layer curing ensures optimal material properties. Bulk curing finds widespread use in the production of large, solid components like automotive parts and construction materials, offering efficiency in curing thick or massive sections. Your choice between continuing curing and bulk curing depends on the desired product scale, structural complexity, and quality standards in your industrial application.

Quality Control in Curing Processes

Continuing curing offers enhanced quality control by allowing precise monitoring and adjustment of temperature and curing time, reducing risks of undercured or overcured materials. Bulk curing enables faster processing but may lead to uneven heat distribution, causing variable mechanical properties and potential defects within the cured product. Implementing real-time sensors and feedback systems improves quality assurance in both methods, ensuring consistent polymer cross-linking and optimal material performance.

Comparative Cost Analysis

Continuing curing often incurs higher labor and energy costs due to prolonged processing times, whereas bulk curing reduces these expenses by treating larger material quantities simultaneously. Equipment investment for bulk curing can be more substantial upfront, but operational efficiency leads to lower per-unit costs over time. Your choice between these methods should consider both immediate budget constraints and long-term production savings to optimize overall cost efficiency.

Environmental Impact of Curing Methods

Continuing curing processes generally consume less energy over time compared to bulk curing, which requires intensive heat and longer durations, contributing to higher carbon emissions. Bulk curing often involves the release of volatile organic compounds (VOCs) and increased solvent use, intensifying environmental pollution. Your choice of curing method can significantly affect the sustainability of production by reducing energy consumption and minimizing harmful emissions.

Choosing the Right Curing Approach

Choosing the right curing approach depends on the thickness and complexity of the resin application. Continuing curing involves applying multiple thin layers cured individually, ensuring thorough polymerization and reducing shrinkage, ideal for intricate or deep restorations. Bulk curing offers faster processing by curing composite in a single, thicker application but requires materials designed for optimal light penetration to avoid incomplete curing or compromised mechanical properties.

Continuing curing vs Bulk curing Infographic

libmatt.com

libmatt.com