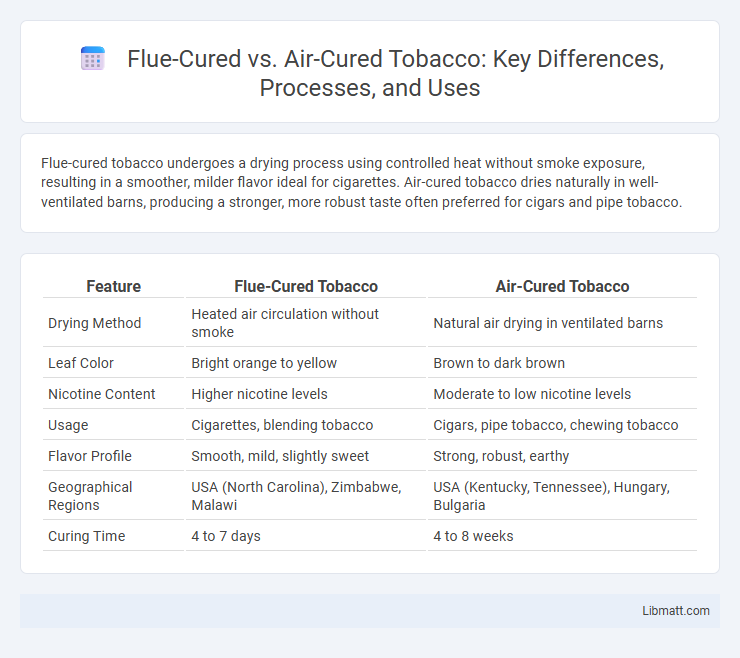

Flue-cured tobacco undergoes a drying process using controlled heat without smoke exposure, resulting in a smoother, milder flavor ideal for cigarettes. Air-cured tobacco dries naturally in well-ventilated barns, producing a stronger, more robust taste often preferred for cigars and pipe tobacco.

Table of Comparison

| Feature | Flue-Cured Tobacco | Air-Cured Tobacco |

|---|---|---|

| Drying Method | Heated air circulation without smoke | Natural air drying in ventilated barns |

| Leaf Color | Bright orange to yellow | Brown to dark brown |

| Nicotine Content | Higher nicotine levels | Moderate to low nicotine levels |

| Usage | Cigarettes, blending tobacco | Cigars, pipe tobacco, chewing tobacco |

| Flavor Profile | Smooth, mild, slightly sweet | Strong, robust, earthy |

| Geographical Regions | USA (North Carolina), Zimbabwe, Malawi | USA (Kentucky, Tennessee), Hungary, Bulgaria |

| Curing Time | 4 to 7 days | 4 to 8 weeks |

Overview of Tobacco Curing Methods

Flue-cured tobacco is dried using controlled heat from flues, producing a bright, mild leaf commonly used in cigarettes, while air-cured tobacco dries naturally through air circulation, resulting in a darker, fuller-bodied leaf often used in cigars and pipe tobacco. The difference in curing methods significantly affects tobacco flavor, moisture content, and chemical composition, influencing the final product's burn quality and taste. Understanding these methods can help you select the right tobacco type for your preferences or cultivation goals.

What is Flue-Cured Tobacco?

Flue-cured tobacco is a type of tobacco cured by drying leaves in an enclosed barn heated with flues, maintaining controlled temperature and humidity to preserve sugar content and enhance flavor. This method produces bright, mild tobacco predominantly used in cigarettes and is primarily grown in regions like North Carolina and parts of the southeastern United States. Flue-cured tobacco contrasts with air-cured varieties by its sweeter, less pungent profile, making it a preferred choice for blending in cigarette manufacturing.

What is Air-Cured Tobacco?

Air-cured tobacco is a type of tobacco that undergoes a slow drying process in well-ventilated barns, allowing the leaves to cure naturally through exposure to air without artificial heat. This method results in a tobacco leaf with lower sugar content and a milder, more robust flavor compared to flue-cured tobacco, which is dried using controlled heat. Commonly used in cigars, pipe tobacco, and snuff, air-cured tobacco retains higher levels of nicotine and has a coarser texture ideal for certain tobacco products.

Key Differences in the Curing Process

Flue-cured tobacco undergoes a controlled drying process using heated air circulated through enclosed barns, allowing precise temperature and humidity regulation to preserve the leaf's sugar content and bright color. Air-cured tobacco, by contrast, dries naturally in well-ventilated barns without artificial heat, resulting in a slower curing process that produces a darker, milder leaf with lower sugar levels and higher nicotine concentration. Understanding these key differences in curing methods can help you select the appropriate tobacco type for your preferred flavor profile and usage.

Impact on Tobacco Flavor and Aroma

Flue-cured tobacco undergoes a controlled drying process using heated air, enhancing its sugar content and producing a sweeter, milder flavor with a smooth aroma ideal for cigarettes. Air-cured tobacco is naturally dried in well-ventilated barns, allowing slow oxidation that intensifies its robust, earthy flavor and rich, smoky aroma preferred in cigars and pipe tobacco. The curing method directly influences nicotine levels and chemical composition, resulting in distinct taste profiles and aromatic qualities between flue-cured and air-cured tobaccos.

Physical Characteristics of Flue-Cured vs Air-Cured

Flue-cured tobacco features a bright yellow to orange color with a smoother, more pliable texture due to its rapid curing process using controlled heat in enclosed barns. Air-cured tobacco, on the other hand, develops a darker brown hue with a denser, coarser leaf structure because it is naturally dried by hanging in well-ventilated barns without artificial heat. These physical differences influence the burn rate and flavor profile, making your choice essential for specific tobacco products.

Uses in Cigarette and Cigar Production

Flue-cured tobacco, characterized by its bright, mild flavor, is predominantly used in cigarette production due to its smooth taste and high sugar content. Air-cured tobacco, with a richer, robust flavor and lower sugar levels, is favored in cigar manufacturing and pipe tobacco for its strength and aromatic qualities. The curing method directly influences the end product's flavor profile, making flue-cured ideal for mild cigarettes and air-cured suited for full-bodied cigars.

Health Implications of Each Curing Method

Flue-cured tobacco is dried using heat-controlled environments that reduce bacterial growth and potentially lower certain harmful compounds compared to air-cured tobacco, which dries naturally and may retain higher levels of toxins such as nitrosamines. The differences in curing affect the chemical composition, with flue-curing often resulting in higher sugar content, leading to a smoother smoke but possibly increased exposure to harmful additives. Understanding these health implications can help you make informed decisions about tobacco products and their associated risks.

Economic and Regional Significance

Flue-cured tobacco dominates the economic landscape in regions like North Carolina and parts of Virginia, where its bright, mild flavor caters to cigarette manufacturers, driving substantial export revenues. Air-cured tobacco, prevalent in Kentucky and Tennessee, supports traditional cigar and pipe tobacco markets, contributing significantly to local economies through niche cultivation and artisanal production. The regional cultivation of these curing methods aligns with soil and climate conditions, influencing employment patterns and agricultural sustainability in these tobacco-producing areas.

Choosing Between Flue-Cured and Air-Cured Tobacco

Flue-cured tobacco is dried using indirect heat in controlled environments, resulting in a sweeter, milder flavor ideal for cigarettes and light smoke blends. Air-cured tobacco is hung in well-ventilated barns, allowing natural drying that produces a stronger, smokier taste preferred for cigars and pipe tobacco. Selecting between flue-cured and air-cured depends on the desired flavor profile, combustion characteristics, and end-use of the tobacco product.

Flue-cured vs air-cured Infographic

libmatt.com

libmatt.com