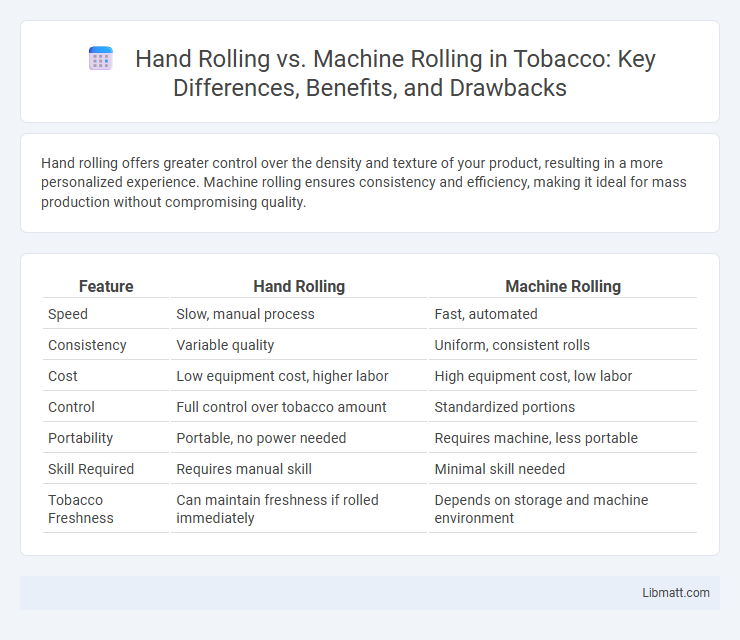

Hand rolling offers greater control over the density and texture of your product, resulting in a more personalized experience. Machine rolling ensures consistency and efficiency, making it ideal for mass production without compromising quality.

Table of Comparison

| Feature | Hand Rolling | Machine Rolling |

|---|---|---|

| Speed | Slow, manual process | Fast, automated |

| Consistency | Variable quality | Uniform, consistent rolls |

| Cost | Low equipment cost, higher labor | High equipment cost, low labor |

| Control | Full control over tobacco amount | Standardized portions |

| Portability | Portable, no power needed | Requires machine, less portable |

| Skill Required | Requires manual skill | Minimal skill needed |

| Tobacco Freshness | Can maintain freshness if rolled immediately | Depends on storage and machine environment |

Introduction to Rolling Techniques

Hand rolling preserves the artisanal quality of cigarettes by allowing skilled rollers to control tobacco density and blend precision, resulting in a personalized smoking experience. Machine rolling employs automated technology to produce cigarettes at high volumes with uniform size and consistency, optimizing efficiency for commercial distribution. Both techniques influence the flavor profile and burn rate, with hand rolling favoring customization and machines prioritizing scalability.

Defining Hand Rolling and Machine Rolling

Hand rolling involves manually shaping and compressing tobacco or other materials using skilled hand movements, ensuring precise control over density and texture. Machine rolling utilizes automated equipment to swiftly produce uniform rolls, significantly increasing production speed and consistency. Both methods are integral to tobacco processing, with hand rolling prized for craftsmanship and machine rolling valued for efficiency.

Materials and Tools Required

Hand rolling requires simple materials such as rolling papers, a filter or crutch, and loose tobacco or herbs, along with your fingers or a small rolling tray for precision. Machine rolling involves using a rolling machine made of plastic or metal to evenly roll materials, typically needing the same papers and contents but offering consistency and speed. Your choice depends on whether you prefer the tactile control of hand rolling or the efficiency and uniformity provided by a rolling machine.

Skill Levels and Learning Curves

Hand rolling requires significant dexterity and practice, as your skill improves with experience, making it ideal for those who enjoy mastering craftsmanship. Machine rolling offers consistent results with minimal effort, suited for users prioritizing speed and uniformity. Understanding these differences helps you choose the method that best matches your skill level and learning preferences.

Precision and Consistency in Results

Hand rolling offers unique craftsmanship that can enhance the texture and flavor of your product, but it often lacks the precision and consistency achieved by machine rolling. Machines utilize advanced technology to ensure uniform pressure and speed, resulting in highly consistent shapes, sizes, and densities that meet exact specifications. For businesses aiming for reliable production standards, machine rolling provides superior repeatability and quality control compared to the variability inherent in hand rolling.

Speed and Efficiency Comparison

Hand rolling cigars offers exceptional control and craftsmanship but is significantly slower, producing only a few cigars per hour. Machine rolling increases speed and efficiency dramatically, generating hundreds of cigars within the same timeframe while maintaining consistent quality. Your choice depends on whether you prioritize artisanal quality or high-volume production efficiency.

Cost Implications: Hand vs. Machine

Hand rolling incurs higher labor costs due to the skilled craftsmanship required, resulting in increased production expenses per unit. Machine rolling significantly reduces labor costs by automating the process, enabling large-scale output and lower per-unit expenses. However, initial investment in machinery and maintenance must be considered when evaluating overall cost efficiency.

Impact on Product Quality

Hand rolling preserves the delicate texture and flavor of tobacco by allowing skilled artisans to control pressure and consistency, resulting in cigars with superior draw and burn characteristics. Machine rolling increases production speed but often compromises the quality by applying uniform pressure that can lead to tighter, less porous cigars affecting flavor development. The artisanal approach in hand rolling enhances the complexity and richness of the final product, making it highly valued by connoisseurs seeking premium smoking experiences.

Environmental Considerations

Hand rolling tobacco generally produces less environmental impact due to minimal machinery use, reducing energy consumption and carbon emissions. Machine rolling requires industrial equipment that consumes significant electricity and generates higher waste levels, from packaging to machinery maintenance. Your choice of hand rolling can support sustainable practices by minimizing reliance on fossil fuels and reducing industrial pollution.

Choosing the Right Method for Your Needs

Hand rolling offers precise control over the size and density of each cigarette, making it ideal for those who prefer a customizable smoking experience and a traditional touch. Machine rolling delivers consistent, uniform cigarettes quickly, suitable for users who prioritize efficiency and volume. Evaluating factors such as time availability, desired quality, and personal preference helps determine the most suitable rolling method.

Hand rolling vs machine rolling Infographic

libmatt.com

libmatt.com