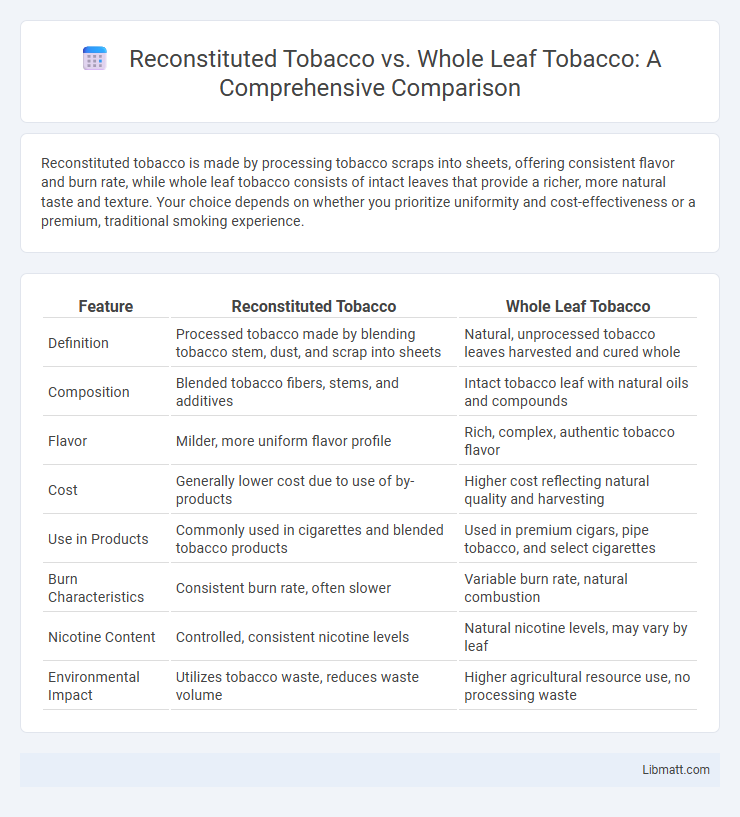

Reconstituted tobacco is made by processing tobacco scraps into sheets, offering consistent flavor and burn rate, while whole leaf tobacco consists of intact leaves that provide a richer, more natural taste and texture. Your choice depends on whether you prioritize uniformity and cost-effectiveness or a premium, traditional smoking experience.

Table of Comparison

| Feature | Reconstituted Tobacco | Whole Leaf Tobacco |

|---|---|---|

| Definition | Processed tobacco made by blending tobacco stem, dust, and scrap into sheets | Natural, unprocessed tobacco leaves harvested and cured whole |

| Composition | Blended tobacco fibers, stems, and additives | Intact tobacco leaf with natural oils and compounds |

| Flavor | Milder, more uniform flavor profile | Rich, complex, authentic tobacco flavor |

| Cost | Generally lower cost due to use of by-products | Higher cost reflecting natural quality and harvesting |

| Use in Products | Commonly used in cigarettes and blended tobacco products | Used in premium cigars, pipe tobacco, and select cigarettes |

| Burn Characteristics | Consistent burn rate, often slower | Variable burn rate, natural combustion |

| Nicotine Content | Controlled, consistent nicotine levels | Natural nicotine levels, may vary by leaf |

| Environmental Impact | Utilizes tobacco waste, reduces waste volume | Higher agricultural resource use, no processing waste |

Introduction to Reconstituted Tobacco and Whole Leaf Tobacco

Reconstituted tobacco is a processed form created by blending tobacco leaf scraps, stems, and dust into a uniform sheet, enhancing consistency and reducing waste in cigarette production. Whole leaf tobacco consists of large, intact leaves harvested directly from the tobacco plant, valued for its natural flavor and traditional smoking experience. Your choice between reconstituted and whole leaf tobacco influences the flavor profile, burn characteristics, and overall quality of the tobacco product.

Composition and Processing Methods

Reconstituted tobacco is created by combining tobacco leaf dust, stems, and scraps into a slurry, which is then formed into sheets, allowing for uniformity and control over nicotine and tar levels, unlike whole leaf tobacco that retains its natural leaf structure with less processing. Whole leaf tobacco undergoes curing and aging without the extensive mechanical breakdown used in reconstituted tobacco, preserving the original leaf's flavor and chemical complexity. The processing of reconstituted tobacco involves blending additives and binders to enhance burn characteristics, while whole leaf relies primarily on its intrinsic composition and traditional curing methods.

Flavor Profile Differences

Reconstituted tobacco offers a consistent and milder flavor profile due to its processed nature, often lacking the complex, robust notes found in whole leaf tobacco. Whole leaf tobacco delivers richer, more nuanced flavor characteristics that vary depending on the leaf's origin, curing, and fermentation processes. Your preference will shape whether you favor the uniform smoothness of reconstituted tobacco or the bold, aromatic intensity of whole leaf.

Burn Rate and Combustion Qualities

Reconstituted tobacco offers a more consistent burn rate compared to whole leaf tobacco, providing uniform combustion and reduced variability in smoking experience. The combustion qualities of reconstituted tobacco are engineered to minimize ash production and maintain steady smoke flow, enhancing overall cigarette performance. In contrast, whole leaf tobacco tends to burn unevenly due to natural variations in leaf structure and moisture content, resulting in less predictable burn and combustion stability.

Cost and Economic Considerations

Reconstituted tobacco reduces production costs by efficiently utilizing tobacco scraps and dust, lowering raw material expenses compared to whole leaf tobacco. Whole leaf tobacco, prized for its quality and natural flavor, often commands a higher market price, increasing overall manufacturing costs. Economically, reconstituted tobacco offers manufacturers a cost-effective alternative that supports sustainable resource use while maintaining product consistency.

Health Implications and Additives

Reconstituted tobacco often contains additives such as sugars, humectants, and flavor enhancers that can increase exposure to harmful chemicals, potentially elevating health risks compared to whole leaf tobacco. Whole leaf tobacco tends to have fewer additives and may result in fewer combustion byproducts due to its less processed nature. Studies indicate that the chemical composition of reconstituted tobacco can lead to higher concentrations of tar and nicotine, intensifying the health implications for users.

Environmental Impact of Production

Reconstituted tobacco production generally has a lower environmental footprint compared to whole leaf tobacco because it utilizes tobacco leaf scraps and stems, reducing agricultural waste. The process requires less land and water resources as it reclaims by-products that would otherwise be discarded. However, the additional processing steps in reconstituted tobacco may involve higher energy consumption and chemical usage, partially offsetting these environmental benefits.

Regulatory Standards and Industry Use

Reconstituted tobacco complies with stringent regulatory standards set by agencies such as the FDA, ensuring consistent nicotine content and reduced harmful substances compared to whole leaf tobacco. The tobacco industry frequently uses reconstituted tobacco to enhance manufacturing efficiency and maintain uniform blend quality, whereas whole leaf tobacco is preferred for premium products requiring natural texture and flavor profiles. Regulatory frameworks often mandate specific labeling and ingredient disclosures for reconstituted tobacco, reflecting its processed nature and chemical modifications.

Consumer Preferences and Market Trends

Consumer preferences show a growing interest in reconstituted tobacco due to its consistent burn quality and lower production cost, appealing to budget-conscious smokers. Whole leaf tobacco maintains a strong market presence for its natural flavor and perceived premium quality, attracting traditional and boutique cigarette consumers. Market trends indicate an increasing blend of both types in cigarette manufacturing to balance cost-efficiency with flavor complexity, reflecting a shift towards product innovation in the tobacco industry.

Future Outlook: Innovations and Trends

Reconstituted tobacco is evolving with breakthroughs in sustainable production methods and enhanced flavor customization, meeting growing consumer demand for eco-friendly alternatives. Whole leaf tobacco maintains its appeal due to natural consistency and authenticity, but technological advances are improving its cultivation and processing efficiency. Your future choices in tobacco products will likely be influenced by innovations combining the benefits of both forms, driven by regulatory pressures and shifting market preferences.

reconstituted tobacco vs whole leaf Infographic

libmatt.com

libmatt.com