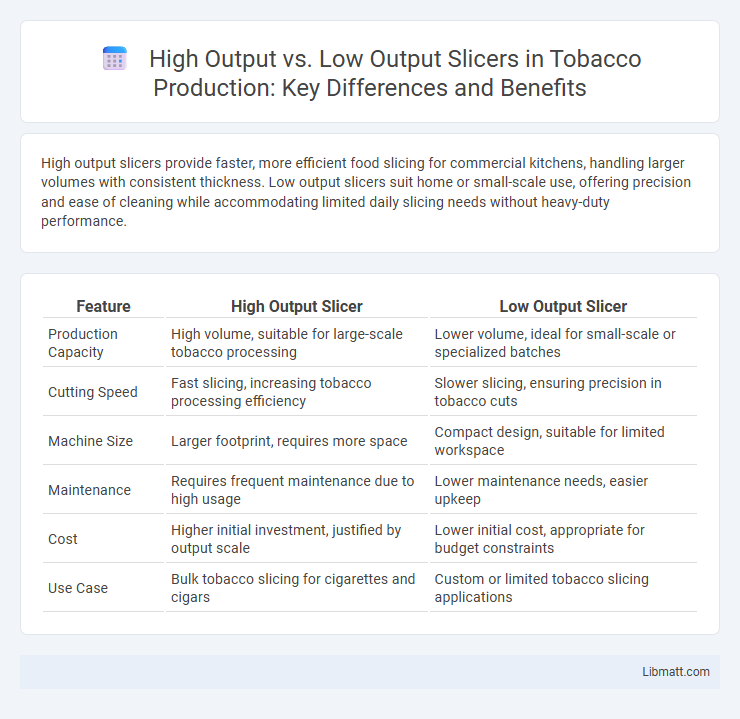

High output slicers provide faster, more efficient food slicing for commercial kitchens, handling larger volumes with consistent thickness. Low output slicers suit home or small-scale use, offering precision and ease of cleaning while accommodating limited daily slicing needs without heavy-duty performance.

Table of Comparison

| Feature | High Output Slicer | Low Output Slicer |

|---|---|---|

| Production Capacity | High volume, suitable for large-scale tobacco processing | Lower volume, ideal for small-scale or specialized batches |

| Cutting Speed | Fast slicing, increasing tobacco processing efficiency | Slower slicing, ensuring precision in tobacco cuts |

| Machine Size | Larger footprint, requires more space | Compact design, suitable for limited workspace |

| Maintenance | Requires frequent maintenance due to high usage | Lower maintenance needs, easier upkeep |

| Cost | Higher initial investment, justified by output scale | Lower initial cost, appropriate for budget constraints |

| Use Case | Bulk tobacco slicing for cigarettes and cigars | Custom or limited tobacco slicing applications |

Understanding Slicer Output Levels

High output slicers generate an amplified audio signal ideal for driving high-impedance inputs or long cable runs without loss of fidelity, while low output slicers produce a weaker signal better suited for direct input into sensitive preamps or mixers with low noise floors. Understanding slicer output levels ensures your equipment matches properly, preventing distortion or signal degradation. Your choice affects overall sound quality and system compatibility, making it essential to evaluate output impedance, gain structure, and intended use.

Key Differences Between High and Low Output Slicers

High output slicers deliver greater power handling capacity and increased signal strength, making them ideal for larger sound systems requiring more bass impact and volume. Low output slicers produce weaker signal strength with lower power, suitable for compact audio setups where clarity and signal integrity are prioritized over loudness. The choice between high and low output slicers depends on system size, desired audio performance, and amplifier compatibility.

Efficiency and Speed Comparison

High output slicers process larger volumes of material at faster speeds, which significantly increases operational efficiency in industrial applications. Low output slicers operate at slower speeds with lower throughput, making them suitable for small-scale or precision slicing tasks where accuracy is critical. The choice between high output and low output slicers depends on balancing the need for rapid processing against the desired slicing quality and volume.

Material Compatibility: High vs Low Output Slicers

High output slicers are designed to handle a wide range of materials, including dense plastics, composites, and specialty filaments, ensuring consistent performance even under demanding conditions. Low output slicers typically work best with standard materials like PLA or ABS, offering limited adaptability to complex or high-strength materials. Your choice between high and low output slicers directly impacts the range of compatible materials and print quality achievable for diverse projects.

Print Quality Considerations

High output slicers prioritize speed and efficiency, often compromising fine details and surface finish, which can lead to visible layer lines and less precise geometries. Low output slicers enhance print quality by optimizing layer height, extrusion width, and print speed to produce smoother surfaces and more accurate feature resolution. Balancing print speed and quality depends on the model's complexity, material properties, and desired application, with low output slicers being ideal for detailed, high-precision parts.

Cost Implications and Investment

High output slicers require a significant upfront investment due to advanced technology and higher capacity components, resulting in increased initial costs but improved long-term efficiency and reduced labor expenses. Low output slicers have lower purchase prices and maintenance costs, making them suitable for smaller operations with limited budgets but may incur higher operational expenses over time. Your choice between high and low output slicers should balance immediate financial constraints with expected production scale and cost-efficiency goals.

Maintenance and Longevity

High output slicers typically require more frequent maintenance due to their increased operational speed and complexity, which can impact their overall longevity if not properly serviced. Low output slicers generally have simpler mechanisms and operate at slower speeds, resulting in less wear and tear and extended lifespan with routine upkeep. Ensuring your slicer is well-maintained according to manufacturer guidelines significantly enhances durability regardless of output capacity.

Application Suitability: Choosing the Right Slicer

High output slicers are ideal for large-scale food processing facilities requiring rapid slicing of consistent product volumes, enhancing efficiency and throughput. Low output slicers suit smaller operations or specialty applications where precision and customization are prioritized over speed. Matching your slicer choice to your production scale and product type ensures optimal performance and cost-effectiveness.

User Experience and Workflow Impact

High output slicers enhance your user experience by enabling faster, more efficient cutting, which significantly improves workflow productivity in busy kitchens or food processing environments. Low output slicers, while suitable for occasional use, often slow down operations due to their limited speed and capacity, potentially causing workflow bottlenecks. Choosing the right slicer directly impacts the smoothness of your work process and overall satisfaction with the equipment.

Future Trends in Slicer Output Technology

High output slicers are rapidly evolving with advancements in automation, AI-driven precision, and enhanced speed capabilities to meet growing industrial demands. Low output slicers continue to adopt smart sensors and energy-efficient technologies, making them ideal for small-scale or artisanal operations requiring consistent quality. Your choice should consider the integration of IoT and machine learning, which are set to revolutionize slicer output technology by optimizing performance and predictive maintenance.

High output vs low output slicer Infographic

libmatt.com

libmatt.com