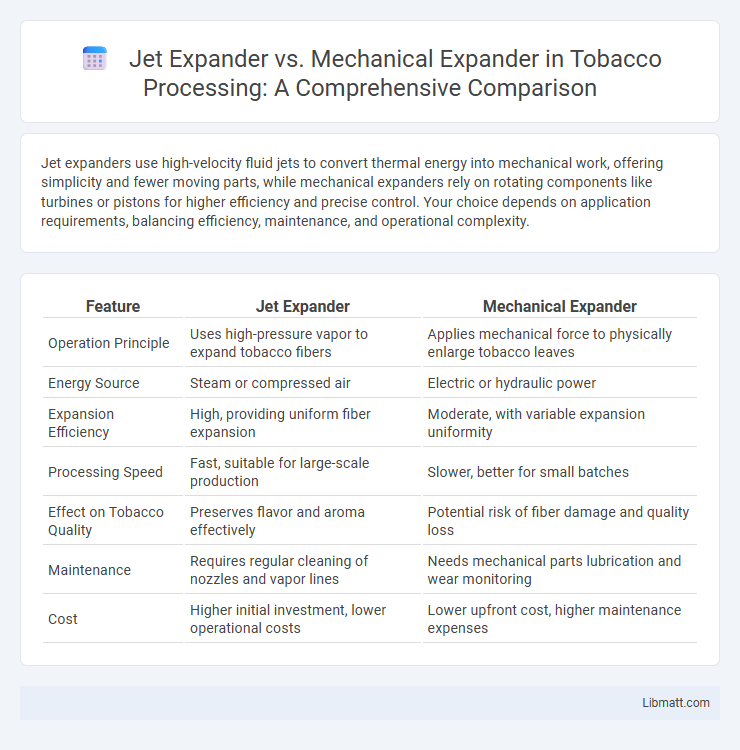

Jet expanders use high-velocity fluid jets to convert thermal energy into mechanical work, offering simplicity and fewer moving parts, while mechanical expanders rely on rotating components like turbines or pistons for higher efficiency and precise control. Your choice depends on application requirements, balancing efficiency, maintenance, and operational complexity.

Table of Comparison

| Feature | Jet Expander | Mechanical Expander |

|---|---|---|

| Operation Principle | Uses high-pressure vapor to expand tobacco fibers | Applies mechanical force to physically enlarge tobacco leaves |

| Energy Source | Steam or compressed air | Electric or hydraulic power |

| Expansion Efficiency | High, providing uniform fiber expansion | Moderate, with variable expansion uniformity |

| Processing Speed | Fast, suitable for large-scale production | Slower, better for small batches |

| Effect on Tobacco Quality | Preserves flavor and aroma effectively | Potential risk of fiber damage and quality loss |

| Maintenance | Requires regular cleaning of nozzles and vapor lines | Needs mechanical parts lubrication and wear monitoring |

| Cost | Higher initial investment, lower operational costs | Lower upfront cost, higher maintenance expenses |

Introduction to Pipeline Expansion Techniques

Jet expansion utilizes high-velocity fluid jets to induce pipeline stretching with precision and minimal mechanical stress, optimizing flow capacity in existing systems. Mechanical expansion involves physically expanding pipeline sections through hydraulic or mechanical tools, ensuring structural integrity during diameter increases. Both techniques address capacity demands but differ in application specifics, operational complexity, and suitability for various pipeline materials and environments.

What is a Jet Expander?

A Jet Expander is a device used in cryogenic and refrigeration systems to expand high-pressure gas into low-pressure gas, producing work and reducing temperature through isentropic expansion. It operates by accelerating the gas through a nozzle, converting pressure energy into kinetic energy, which results in cooling without mechanical moving parts. Unlike mechanical expanders, Jet Expanders have fewer maintenance requirements and are suitable for specific applications where simplicity and reliability are prioritized over maximum efficiency.

What is a Mechanical Expander?

A mechanical expander is a drilling tool used to enlarge boreholes by physically cutting and removing rock with a rotating cutting structure. Unlike jet expanders that rely on high-pressure fluid jets to erode the formation, mechanical expanders use cutting arms or rollers to expand the hole diameter efficiently. This method provides precise hole enlargement and improves hole stability in various geological formations during drilling operations.

Working Principles: Jet vs Mechanical Expanders

Jet expanders operate by using high-velocity fluid jets to convert pressure energy into mechanical work, relying on fluid dynamics for expansion. Mechanical expanders utilize rotating components like turbines or screws to directly transform pressure energy into rotational energy, enhancing efficiency in energy recovery systems. Understanding these working principles helps you choose the optimal expander type for specific industrial applications based on fluid properties and energy output requirements.

Efficiency Comparison: Jet and Mechanical Expanders

Jet expanders achieve higher efficiency in low-temperature differential applications by utilizing high-velocity fluid jets to rapidly expand gases, minimizing energy losses. Mechanical expanders, such as turbines and pistons, offer superior efficiency in high-pressure and temperature environments due to their ability to convert mechanical work more effectively with reduced leakage and friction. Efficiency comparison shows jet expanders excel in lightweight, compact systems, while mechanical expanders dominate in large-scale industrial processes requiring reliable energy recovery.

Installation and Maintenance Requirements

Jet expanders typically require simpler installation with fewer moving parts, making them easier to set up and maintain, especially in compact or low-maintenance environments. Mechanical expanders involve more complex assemblies requiring precise alignment and routine lubrication to ensure optimal performance and longevity. Your choice should consider the available maintenance resources and installation constraints to balance efficiency and upkeep.

Cost Implications of Each Method

Jet expanders generally have lower initial capital costs due to simpler design and fewer moving parts, making them cost-effective for smaller-scale applications. Mechanical expanders involve higher upfront investment because of complex components and maintenance requirements, leading to increased operational expenses over time. Cost efficiency depends on scale, with jet expanders favored for low to medium capacity and mechanical expanders more suitable for large-scale, high-efficiency operations.

Application Suitability and Industry Use Cases

Jet expanders excel in applications requiring high efficiency in recovering energy from high-pressure steam, making them suitable for power generation and steam turbine plants. Mechanical expanders are preferred in industries like refrigeration, HVAC, and natural gas processing due to their capability to handle lower pressure differentials and provide precise rotational output. Your choice depends on the specific pressure conditions and energy recovery requirements of your industrial process.

Advantages and Disadvantages: Jet vs Mechanical

Jet expanders offer advantages such as fewer moving parts, leading to lower maintenance costs and smoother operation in high-speed applications. Mechanical expanders provide greater control and efficiency in energy recovery due to precise torque management but involve more complex designs and higher initial costs. Your choice depends on whether you prioritize low maintenance and simplicity (jet expander) or enhanced efficiency and controllability (mechanical expander).

Choosing the Right Expander for Your Pipeline Project

Jet expanders use high-velocity fluid jets to expand pipe diameters, offering precise control and reduced mechanical stress, making them ideal for projects requiring minimal structural impact. Mechanical expanders rely on physical force applied by rollers or cones to plastically deform pipes, providing robust expansion for thicker materials or more demanding pipeline specifications. Your choice depends on factors like pipe material, expansion precision, project scale, and operational conditions, ensuring optimal performance and longevity of your pipeline system.

Jet expander vs mechanical expander Infographic

libmatt.com

libmatt.com