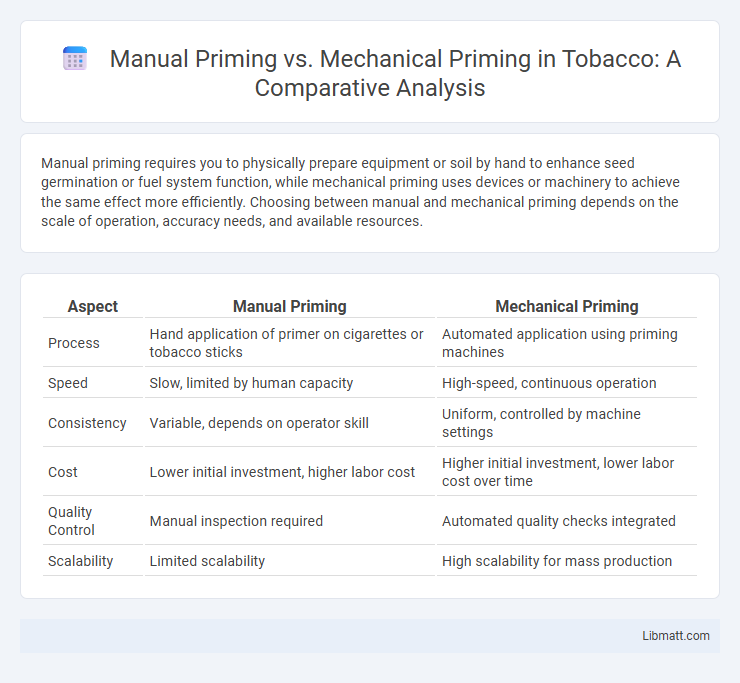

Manual priming requires you to physically prepare equipment or soil by hand to enhance seed germination or fuel system function, while mechanical priming uses devices or machinery to achieve the same effect more efficiently. Choosing between manual and mechanical priming depends on the scale of operation, accuracy needs, and available resources.

Table of Comparison

| Aspect | Manual Priming | Mechanical Priming |

|---|---|---|

| Process | Hand application of primer on cigarettes or tobacco sticks | Automated application using priming machines |

| Speed | Slow, limited by human capacity | High-speed, continuous operation |

| Consistency | Variable, depends on operator skill | Uniform, controlled by machine settings |

| Cost | Lower initial investment, higher labor cost | Higher initial investment, lower labor cost over time |

| Quality Control | Manual inspection required | Automated quality checks integrated |

| Scalability | Limited scalability | High scalability for mass production |

Introduction to Manual and Mechanical Priming

Manual priming involves physically activating a pump or system by hand to remove air and ensure fluid flow, typically used in smaller or portable equipment. Mechanical priming employs automated or motor-driven components to facilitate the priming process, enhancing efficiency and consistency in larger or industrial pumps. Understanding the differences in application, efficiency, and operational context is crucial for selecting the appropriate priming method.

Definition and Overview of Priming Methods

Manual priming involves using hand-operated tools or techniques to prepare a surface or system, often requiring physical effort and direct control over the process. Mechanical priming utilizes machines or automated equipment to apply primer, ensuring consistent coverage and efficiency in large-scale or industrial applications. Both methods aim to enhance adhesion and surface readiness but differ significantly in scale, precision, and labor intensity.

Key Differences Between Manual and Mechanical Priming

Manual priming involves physically pumping a primer bulb or lever to initiate fluid flow, offering precise control and simplicity ideal for small-scale or maintenance tasks. Mechanical priming utilizes automated pumps or motor-driven mechanisms to achieve consistent and rapid fluid movement, enhancing efficiency for large-scale or continuous operations. Key differences include the level of operator effort, speed of priming, and suitability for different applications, with mechanical priming providing speed and automation while manual priming emphasizes control and cost-effectiveness.

Advantages of Manual Priming

Manual priming offers precise control over the amount of fuel delivered, preventing flooding and ensuring optimal engine performance. Your ability to manually adjust the fuel flow provides better responsiveness, especially in small engines or intricate machinery. This method is cost-effective and requires minimal equipment, making it ideal for maintenance and troubleshooting tasks.

Advantages of Mechanical Priming

Mechanical priming ensures consistent and precise fuel delivery, reducing the risk of air bubbles and improving engine start-up reliability. It significantly saves time and effort compared to manual priming, especially in high-demand or industrial applications where speed and efficiency are critical. Enhanced durability and reduced operator fatigue make mechanical priming the preferred choice for advanced fuel systems in modern machinery.

Disadvantages and Limitations of Manual Priming

Manual priming often leads to inconsistent fuel delivery due to variable hand pressure and speed, which can cause engine performance issues. The process is time-consuming and physically demanding, increasing the risk of operator fatigue and human error. Your engine's reliability may suffer as manual priming lacks the precision and efficiency provided by mechanical priming systems.

Disadvantages and Limitations of Mechanical Priming

Mechanical priming systems often face limitations such as high initial costs, complex maintenance requirements, and potential failure due to mechanical wear or power outages. Unlike manual priming, mechanical priming may lack flexibility in adapting to unexpected conditions or precise pressure control, which can affect system reliability. Your reliance on mechanical priming could lead to downtime or increased operational expenses if these disadvantages are not carefully managed.

Applications and Industry Use Cases

Manual priming is widely used in small-scale applications such as home gardening, automotive maintenance, and laboratory settings where precision and control are critical. Mechanical priming finds extensive use in industrial sectors like manufacturing, agriculture, and construction, offering efficiency and consistency for large-scale operations involving pumps, engines, and fluid systems. Your choice between manual and mechanical priming depends on the scale, accuracy, and frequency required by specific industry use cases.

Safety Considerations in Priming Techniques

Manual priming requires extra caution to avoid air embolism and contamination, as improper handling can introduce air bubbles or pathogens into the system. Mechanical priming, often automated through devices with built-in safeguards, reduces these risks by ensuring consistent and controlled fluid flow. Your safety is enhanced when using equipment with alarm systems and pressure sensors that prevent common priming errors.

Choosing the Right Priming Method: Factors to Consider

When choosing the right priming method, consider factors such as the size and complexity of the system, the type of fluid, and the required precision. Manual priming offers control and is suitable for smaller or less complex setups, while mechanical priming provides consistency and is ideal for large-scale or automated systems. Understanding your system's operational needs and maintenance capabilities ensures your priming method optimizes performance and reliability.

manual priming vs mechanical priming Infographic

libmatt.com

libmatt.com