Micro-perforated papers feature tiny holes that enhance breathability and reduce glare, making them ideal for acoustic insulation and privacy applications. Macro-perforated papers have larger holes designed for ventilation and filtration purposes, offering greater airflow but less subtlety compared to micro-perforation.

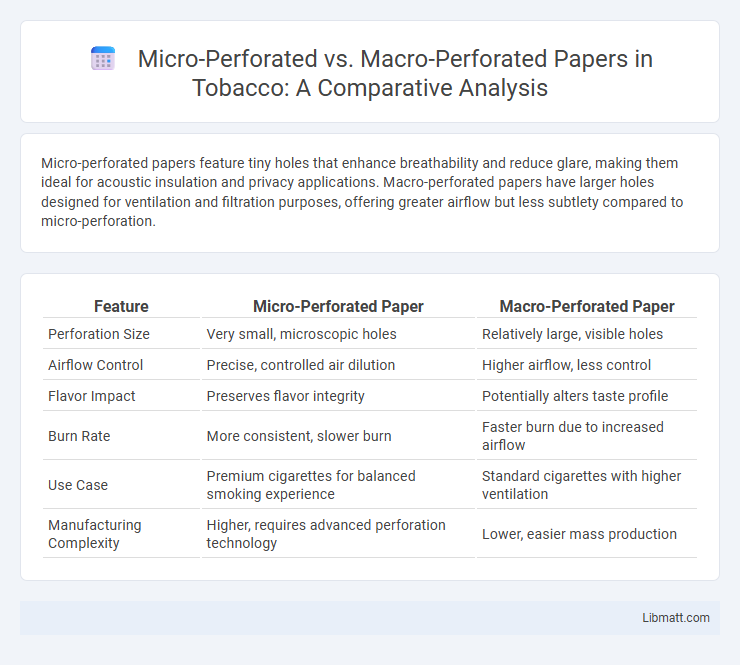

Table of Comparison

| Feature | Micro-Perforated Paper | Macro-Perforated Paper |

|---|---|---|

| Perforation Size | Very small, microscopic holes | Relatively large, visible holes |

| Airflow Control | Precise, controlled air dilution | Higher airflow, less control |

| Flavor Impact | Preserves flavor integrity | Potentially alters taste profile |

| Burn Rate | More consistent, slower burn | Faster burn due to increased airflow |

| Use Case | Premium cigarettes for balanced smoking experience | Standard cigarettes with higher ventilation |

| Manufacturing Complexity | Higher, requires advanced perforation technology | Lower, easier mass production |

Introduction to Perforated Papers

Perforated papers are specialized papers featuring small holes designed to enhance breathability and flexibility, categorized mainly into micro-perforated and macro-perforated types based on hole size. Micro-perforated papers contain tiny, densely packed holes that improve air circulation while maintaining structural integrity, ideal for applications requiring subtle ventilation like packaging and printing. Macro-perforated papers have larger and fewer holes, offering more pronounced breathability suited for purposes like disposable products and decorative uses, allowing you to select the optimal paper type based on your project's ventilation and strength needs.

What is Micro-Perforation?

Micro-perforation refers to the technique of creating tiny, closely spaced holes in paper to enhance breathability and flexibility without compromising strength. This method improves tear resistance and allows for easy tearing along the perforated lines, making it ideal for packaging, tickets, and labels where controlled separation is needed. Your choice of micro-perforated paper can optimize product functionality by balancing durability with user convenience.

What is Macro-Perforation?

Macro-perforation refers to paper or material with larger, visible holes or slits, typically exceeding 1 millimeter in diameter, designed to allow easier tearing, ventilation, or drainage. Unlike micro-perforated paper, which features tiny, nearly invisible perforations for controlled breathability or light passage, macro-perforated materials prioritize functional separation and stronger airflow. Understanding macro-perforation helps you select the right paper type for applications requiring durability combined with easy separation or filtration.

Manufacturing Differences

Micro-perforated papers are produced using precision laser or mechanical techniques to create tiny, evenly distributed holes typically less than 1 millimeter in diameter, enabling controlled breathability and enhanced acoustic properties. Macro-perforated papers involve larger holes, generally above 1 millimeter, created through conventional punching or die-cutting methods, resulting in greater permeability and airflow but reduced structural integrity. These manufacturing differences directly impact the paper's applications, with micro-perforation demanding higher precision equipment and quality control compared to the simpler, faster macro-perforation processes.

Applications of Micro-Perforated Papers

Micro-perforated papers are widely used in sound absorption applications within automotive interiors, recording studios, and office acoustic panels due to their ability to dissipate sound energy without traditional porous materials. These papers provide enhanced breathability and moisture control in packaging, particularly for food products, improving shelf life while maintaining hygiene standards. In addition, micro-perforated paper serves as an effective barrier in printing and specialty paper manufacturing, facilitating precise ink distribution and drying processes.

Applications of Macro-Perforated Papers

Macro-perforated papers are commonly used in packaging, filtration, and decorative applications due to their larger hole size, which allows for better airflow, moisture control, and visibility. These papers are ideal for producing breathable bags, promotional materials, and gift wraps that require structural integrity combined with ventilation. Your choice of macro-perforated paper can enhance product protection while maintaining aesthetic appeal in various commercial and industrial uses.

Benefits of Micro-Perforated Papers

Micro-perforated papers offer enhanced breathability and moisture control, improving comfort in applications like packaging and hygiene products. Their fine perforations provide effective ventilation while maintaining strength and durability, reducing the risk of contamination. These papers also enable better ink adhesion and print quality compared to macro-perforated alternatives, benefiting high-resolution graphic designs.

Benefits of Macro-Perforated Papers

Macro-perforated papers offer superior breathability and enhanced airflow, making them ideal for applications requiring moisture control and ventilation. Their larger perforations improve drainage and drying times, reducing the risk of mold and mildew buildup in packaging or construction materials. You can leverage macro-perforated papers to achieve better durability and structural integrity while maintaining flexibility in various industrial and commercial uses.

Key Differences: Micro vs Macro

Micro-perforated papers feature tiny, closely spaced holes typically less than 1 mm in diameter, enhancing breathability and moisture control without compromising strength. Macro-perforated papers have larger, widely spaced perforations generally over 1 mm, allowing greater air and liquid passage but reducing structural integrity. The choice between micro and macro perforations depends on the application's need for ventilation, durability, and filtration efficiency.

Choosing the Right Perforation for Your Needs

Micro-perforated papers feature tiny, closely spaced holes that provide subtle tear lines ideal for precise, controlled perforation without compromising the paper's strength or print quality. Macro-perforated papers have larger, widely spaced holes suited for easy tearing and quick separation in applications like coupons, tickets, or forms. Choosing the right perforation depends on your need for either delicate, clean separations with micro-perforations or more visible, effortless tearing with macro-perforations to enhance user experience.

micro-perforated vs macro-perforated papers Infographic

libmatt.com

libmatt.com