Coil-cut wood features long, continuous fibers that provide superior strength and a smooth texture, making it ideal for applications requiring durability and aesthetic appeal. Strand-cut wood, composed of shorter strands compressed together, offers enhanced stability and resistance to warping, which is advantageous for flooring and engineered wood products.

Table of Comparison

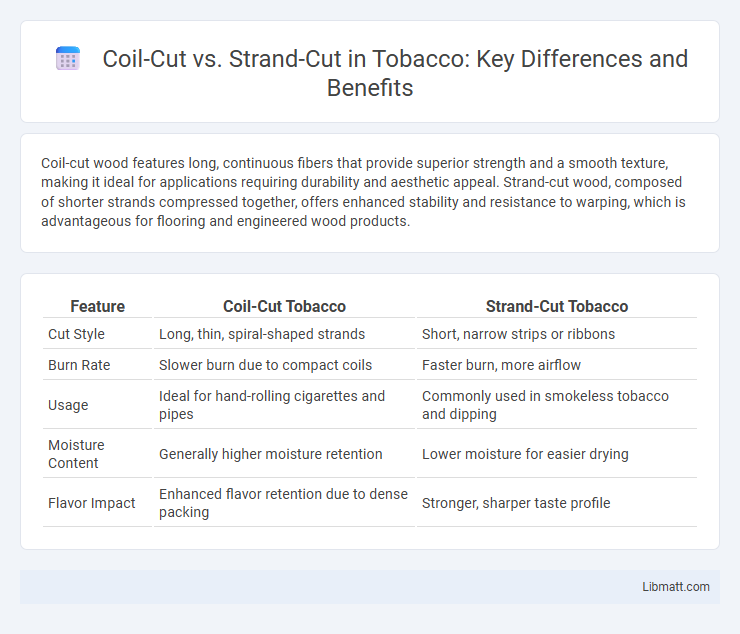

| Feature | Coil-Cut Tobacco | Strand-Cut Tobacco |

|---|---|---|

| Cut Style | Long, thin, spiral-shaped strands | Short, narrow strips or ribbons |

| Burn Rate | Slower burn due to compact coils | Faster burn, more airflow |

| Usage | Ideal for hand-rolling cigarettes and pipes | Commonly used in smokeless tobacco and dipping |

| Moisture Content | Generally higher moisture retention | Lower moisture for easier drying |

| Flavor Impact | Enhanced flavor retention due to dense packing | Stronger, sharper taste profile |

Introduction to Cutting Methods

Coil-cut and strand-cut are distinct cutting methods used in manufacturing, each designed to optimize material handling and processing efficiency. Coil-cutting involves slicing continuous coils of metal or other materials into predefined lengths, ideal for high-volume production with minimal waste. Strand-cutting, by contrast, separates materials into thinner, narrower strands or strips, offering precision for applications requiring smaller, uniform components tailored to Your specific manufacturing needs.

What is Coil-Cut?

Coil-cut refers to the process of cutting wire or metal strips directly from a continuous coil into specific lengths or shapes without separating individual strands. This method enhances manufacturing efficiency by minimizing material waste and reducing processing time. Its applications are common in industries requiring precise metal components, such as automotive, electronics, and construction.

What is Strand-Cut?

Strand-cut refers to a method of processing wood where logs are shredded into long, thin strands before being bonded with adhesive to form engineered wood products. This technique enhances the structural integrity and flexibility of materials like oriented strand board (OSB), making them ideal for construction and industrial applications. Strand-cut wood offers superior strength and resistance compared to traditional wood products due to its unique fiber orientation and adhesive bonding.

Key Differences Between Coil-Cut and Strand-Cut

Coil-cut and strand-cut refer to different methods of processing wood fibers for engineered wood products. Coil-cut wood fibers maintain longer strands, which provide enhanced strength and flexibility, while strand-cut fibers are shorter and more uniform, resulting in a denser and smoother surface ideal for furniture and flooring. Understanding these differences helps you choose the right material for durability, aesthetic, and application-specific needs.

Material Applications: Coil-Cut vs Strand-Cut

Coil-cut material is primarily used in applications requiring thin, uniform sheets such as roofing, automotive panels, and appliance manufacturing due to its consistent thickness and smooth surface. Strand-cut material, with its fibrous, textured profile, excels in filtration, soundproofing, and insulation tasks where increased surface area and enhanced mechanical bonding are beneficial. The choice between coil-cut and strand-cut hinges on the specific mechanical properties and surface characteristics needed for optimal performance in diverse industrial sectors.

Advantages of Coil-Cut Process

The coil-cut process offers improved precision and reduced material waste compared to strand-cut methods, resulting in higher efficiency and lower production costs. This technique provides better control over coil tension and alignment, enhancing the quality and consistency of the final product. Your manufacturing operations benefit from faster processing speeds and enhanced surface finish, making coil-cut an advantageous choice for high-volume metal fabrication.

Benefits of Strand-Cut Method

Strand-cut lumber offers enhanced strength and stability compared to coil-cut alternatives, making it ideal for structural applications. The method produces longer, thinner strands that improve nail-holding capacity and reduce warping, ensuring durable and reliable construction. Your projects benefit from increased resistance to splitting and uniform density through the strand-cut technique.

Cost Comparison: Coil-Cut vs Strand-Cut

Coil-cut wood typically offers a lower upfront cost due to less processing complexity compared to strand-cut wood, which requires additional steps like shredding and bonding. Strand-cut products, while more expensive initially, provide enhanced durability and structural integrity, potentially reducing long-term maintenance expenses. Evaluating both immediate price and lifecycle costs is crucial for cost-efficient decision-making in construction or manufacturing projects.

Industry Use Cases

Coil-cut layers excel in transformer manufacturing and high-frequency inductors due to their continuous, uniform thickness and superior electrical insulation properties. Strand-cut laminations are preferred in large industrial motors and generators because their grain-oriented texture reduces core losses and improves magnetic performance under heavy load conditions. Both cutting techniques optimize efficiency and durability according to specific electromagnetic and mechanical demands in power generation and electrical machinery industries.

Choosing the Right Method for Your Needs

Coil-cut steel offers smooth edges and is ideal for applications requiring precise sheet dimensions and minimal waste, while strand-cut steel provides increased flexibility and strength due to its layered grain structure. Your choice between coil-cut and strand-cut should consider factors like the desired finish, mechanical properties, and specific structural requirements. Understanding these differences ensures optimal material performance tailored to your project's needs.

coil-cut vs strand-cut Infographic

libmatt.com

libmatt.com