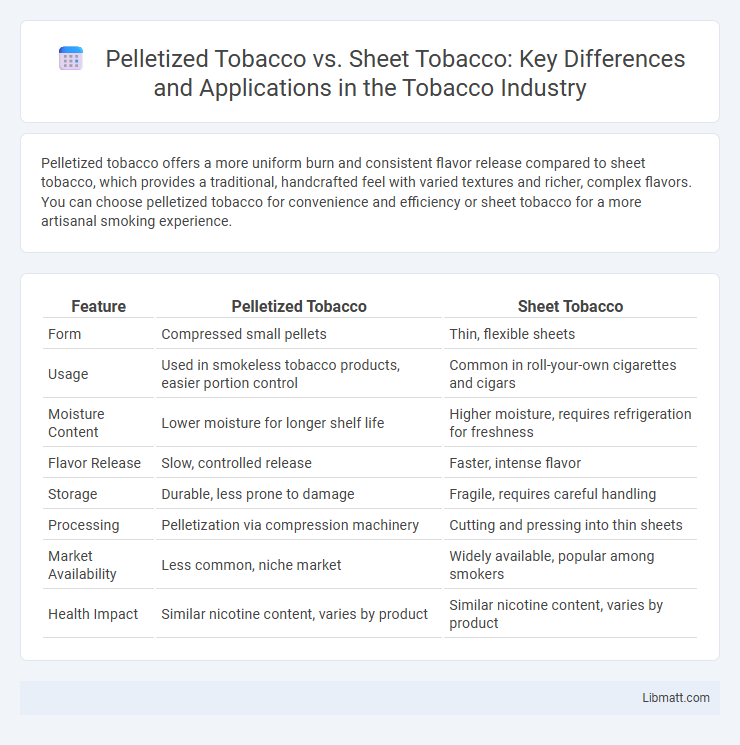

Pelletized tobacco offers a more uniform burn and consistent flavor release compared to sheet tobacco, which provides a traditional, handcrafted feel with varied textures and richer, complex flavors. You can choose pelletized tobacco for convenience and efficiency or sheet tobacco for a more artisanal smoking experience.

Table of Comparison

| Feature | Pelletized Tobacco | Sheet Tobacco |

|---|---|---|

| Form | Compressed small pellets | Thin, flexible sheets |

| Usage | Used in smokeless tobacco products, easier portion control | Common in roll-your-own cigarettes and cigars |

| Moisture Content | Lower moisture for longer shelf life | Higher moisture, requires refrigeration for freshness |

| Flavor Release | Slow, controlled release | Faster, intense flavor |

| Storage | Durable, less prone to damage | Fragile, requires careful handling |

| Processing | Pelletization via compression machinery | Cutting and pressing into thin sheets |

| Market Availability | Less common, niche market | Widely available, popular among smokers |

| Health Impact | Similar nicotine content, varies by product | Similar nicotine content, varies by product |

Introduction to Pelletized and Sheet Tobacco

Pelletized tobacco consists of finely ground tobacco compressed into small pellets, offering consistent burn rates and convenient handling for use in various smoking products. Sheet tobacco is produced by pressing shredded tobacco leaves into thin sheets, often used in roll-your-own cigarettes and specialized products due to its flexible texture and customizable thickness. Both forms cater to different consumer preferences and manufacturing processes, emphasizing ease of use and tailored smoking experiences.

What is Pelletized Tobacco?

Pelletized tobacco is finely ground tobacco processed into small, uniform pellets for consistent burning and controlled nicotine release. This form enhances combustion efficiency and is commonly used in products like smokeless tobacco and heat-not-burn devices. Pelletized tobacco offers a more precise and cleaner smokeless tobacco experience compared to traditional sheet tobacco, which is sold in thin, flat leaves.

What is Sheet Tobacco?

Sheet tobacco is a form of processed tobacco created by compressing and cutting tobacco leaves into thin, flexible sheets designed for easy handling and rolling. Unlike pelletized tobacco, which is formed into small granules or pellets for specific devices, sheet tobacco maintains the traditional leaf structure, allowing for a more natural smoking experience. Your choice between pelletized and sheet tobacco depends on the preferred usage method and desired flavor intensity.

Manufacturing Process: Pelletized vs Sheet

Pelletized tobacco undergoes a process where finely shredded tobacco leaves are compacted into uniform pellets through extrusion or compression methods, ensuring consistent size and moisture content for easy handling and dosing. In contrast, sheet tobacco is produced by pressing tobacco leaves into thin, flexible sheets by using specialized rollers or calenders, which preserve the leaf's texture and enable diverse cutting options for various tobacco products. The pelletized form offers enhanced storage stability and automated processing compatibility, while sheet tobacco maintains the natural leaf structure favored in premium blends and handcrafted products.

Flavor and Burn Characteristics

Pelletized tobacco offers a consistent, slow burn with a concentrated flavor, making it ideal for users who prefer uniform taste and prolonged smoking sessions. Sheet tobacco, on the other hand, provides a richer, more traditional tobacco flavor due to its natural leaf structure, but it tends to burn faster and less evenly compared to pelletized forms. Understanding these differences helps you select the tobacco type that best matches your flavor preferences and desired burn experience.

Impact on Cigarette Quality

Pelletized tobacco offers consistent moisture content and uniform particle size, which enhances combustion control and leads to a smoother, more even burn in cigarettes. Sheet tobacco, composed of compressed tobacco leaves, provides richer flavor complexity but may result in uneven burning due to variable thickness and moisture distribution. The choice between pelletized and sheet tobacco significantly influences cigarette quality by balancing flavor richness against burn consistency and smoke smoothness.

Cost Comparison and Production Efficiency

Pelletized tobacco generally offers lower production costs due to automated manufacturing processes and reduced labor requirements, making it more cost-effective than sheet tobacco. Sheet tobacco production involves more manual handling and higher material waste, increasing overall expenses and decreasing efficiency. Choosing pelletized tobacco can optimize your operations by balancing lower costs with streamlined production workflows.

Health and Regulatory Considerations

Pelletized tobacco undergoes extensive processing, which may introduce additives and chemicals potentially affecting its health profile compared to less-processed sheet tobacco. Regulatory frameworks often classify pelletized tobacco under stricter controls due to its concentrated nicotine delivery and added substances, leading to more rigorous labeling and marketing restrictions. Health authorities emphasize monitoring pelletized tobacco for increased risks of addiction and adverse effects, whereas sheet tobacco, being more natural and less concentrated, might face relatively fewer regulatory burdens.

Environmental Footprint and Sustainability

Pelletized tobacco generally has a lower environmental footprint due to its efficient production process that minimizes waste and energy consumption compared to sheet tobacco, which requires extensive processing and chemical treatments. Sustainability efforts in pelletized tobacco focus on reducing carbon emissions and utilizing renewable resources, whereas sheet tobacco's larger water usage and chemical inputs pose greater environmental challenges. Choosing pelletized tobacco can reduce Your impact on natural resources, supporting a more sustainable tobacco industry.

Future Trends in Tobacco Processing

Pelletized tobacco is gaining traction due to its uniform particle size, enabling precise dosing and enhanced flavor consistency, while sheet tobacco remains valued for traditional cigarette manufacturing and flexible product design. Innovations in automation and sustainability are driving the shift towards pelletized formats, reducing waste and improving production efficiency. Future trends emphasize eco-friendly processing technologies, integration of AI for quality control, and development of hybrid tobacco forms combining pelletized precision with sheet tobacco versatility.

Pelletized tobacco vs Sheet tobacco Infographic

libmatt.com

libmatt.com