Sheet tobacco offers a convenient, uniform option for rolling or wrapping cigars, while whole leaf provides a more natural, traditional experience with enhanced flavor complexity. Choosing between sheet tobacco and whole leaf depends on your preference for ease of use versus authenticity in tobacco craftsmanship.

Table of Comparison

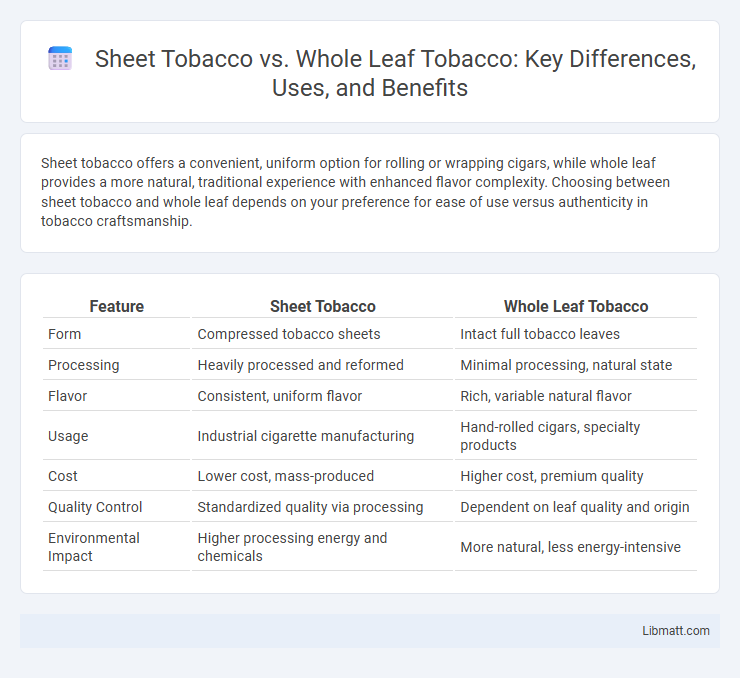

| Feature | Sheet Tobacco | Whole Leaf Tobacco |

|---|---|---|

| Form | Compressed tobacco sheets | Intact full tobacco leaves |

| Processing | Heavily processed and reformed | Minimal processing, natural state |

| Flavor | Consistent, uniform flavor | Rich, variable natural flavor |

| Usage | Industrial cigarette manufacturing | Hand-rolled cigars, specialty products |

| Cost | Lower cost, mass-produced | Higher cost, premium quality |

| Quality Control | Standardized quality via processing | Dependent on leaf quality and origin |

| Environmental Impact | Higher processing energy and chemicals | More natural, less energy-intensive |

Introduction to Sheet Tobacco and Whole Leaf

Sheet tobacco consists of thin, compressed layers of tobacco leaves often used in cigars, cigarettes, and vaping products, providing consistent flavor and burn characteristics. Whole leaf tobacco refers to unprocessed, intact tobacco leaves prized for their natural oils and rich flavor, commonly used in premium cigars and roll-your-own tobacco. The choice between sheet tobacco and whole leaf impacts product quality, flavor complexity, and manufacturing techniques.

What is Sheet Tobacco?

Sheet tobacco is a processed and compressed form of tobacco leaves, often used in manufacturing cigarettes or cigars for consistent quality and easier handling. Unlike whole leaf tobacco, which retains the natural shape and texture of the original leaves, sheet tobacco is crafted by blending and pressing tobacco pulp into thin, uniform sheets. Your choice between sheet tobacco and whole leaf depends on whether you prioritize convenience and consistency or natural texture and flavor in tobacco products.

What is Whole Leaf Tobacco?

Whole leaf tobacco consists of entire, unprocessed tobacco leaves harvested from the plant, preserving their natural structure and flavor profile. This type offers a richer, more authentic smoking experience compared to sheet tobacco, which is reconstituted from tobacco scraps and additives. Your preference for smoky taste or natural texture often determines the choice between whole leaf and sheet tobacco products.

Manufacturing Process Comparison

Sheet tobacco is produced by shredding tobacco leaves into fine strands, which are then processed and formed into thin sheets using adhesives and binding agents. Whole leaf tobacco, in contrast, preserves the entire uncut leaf through curing and drying, maintaining its natural structure and texture without any additional processing. Your choice between sheet and whole leaf tobacco impacts not only the manufacturing complexity but also the flavor profile and product quality.

Flavor Profiles: Sheet vs. Whole Leaf

Sheet tobacco offers a consistent flavor profile, often engineered to provide a balanced blend of sweetness and mild spice, making it ideal for uniform smoking experiences. Whole leaf tobacco, in contrast, delivers a richer, more complex flavor with natural oils and textures that enhance the taste, offering a more robust and authentic tobacco experience. Your choice between sheet and whole leaf will significantly influence the intensity and depth of the flavor in your tobacco products.

Cost Differences

Sheet tobacco typically costs more than whole leaf tobacco due to its additional processing, including shredding, flavor adding, and packaging, which increases production expenses. Whole leaf tobacco, being less processed and closer to its natural state, offers a more economical option for smokers and cigar rollers. Price variations also depend on tobacco quality, origin, and supply chain factors, but sheet tobacco consistently carries higher costs in retail settings.

Uses in Cigars and Cigarettes

Sheet tobacco is thinly pressed and commonly used as binder or filler in both cigars and cigarettes, offering consistency and ease of handling during manufacturing. Whole leaf tobacco, prized for its natural structure, is primarily used in premium cigars to provide superior flavor and an authentic smoking experience. Your choice between sheet and whole leaf tobacco impacts the cigar or cigarette's burn quality, flavor complexity, and overall smoking satisfaction.

Health and Additive Considerations

Sheet tobacco typically contains more additives and chemicals used for flavoring and burning consistency, increasing health risks compared to whole leaf tobacco. Whole leaf tobacco is less processed, often free from synthetic additives, providing a more natural smoking option that reduces exposure to harmful substances. Your choice between these two affects the level of additives inhaled, influencing overall health outcomes.

Environmental Impact

Sheet tobacco manufacturing involves significant energy consumption and chemical usage, contributing to higher carbon emissions and pollution compared to whole leaf tobacco, which typically requires less processing. Whole leaf tobacco preserves the natural structure, leading to reduced waste and lower water usage during production. Choosing whole leaf tobacco can help minimize environmental impact through decreased resource consumption and less industrial processing.

Choosing Between Sheet and Whole Leaf Tobacco

Choosing between sheet tobacco and whole leaf tobacco depends on your rolling preference and desired consistency; sheet tobacco offers uniformity and ease for beginners, while whole leaf tobacco provides a more natural, robust flavor experience preferred by enthusiasts. Sheet tobacco, processed into thin, even layers, ensures smooth rolling and consistent burn, making it ideal for those seeking convenience and predictability. Whole leaf tobacco maintains the integrity of the leaf, delivering stronger flavor profiles and allowing custom rolling techniques for a personalized smoking experience.

Sheet tobacco vs Whole leaf Infographic

libmatt.com

libmatt.com