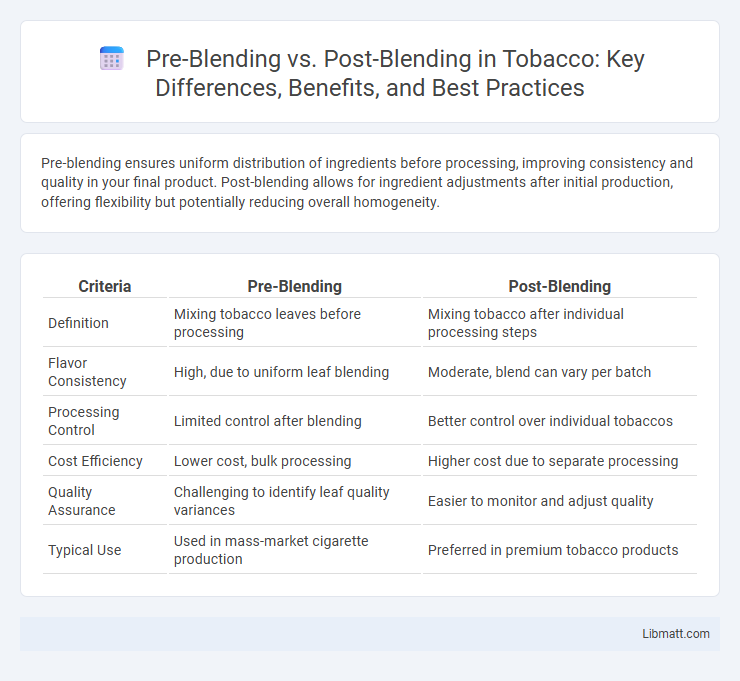

Pre-blending ensures uniform distribution of ingredients before processing, improving consistency and quality in your final product. Post-blending allows for ingredient adjustments after initial production, offering flexibility but potentially reducing overall homogeneity.

Table of Comparison

| Criteria | Pre-Blending | Post-Blending |

|---|---|---|

| Definition | Mixing tobacco leaves before processing | Mixing tobacco after individual processing steps |

| Flavor Consistency | High, due to uniform leaf blending | Moderate, blend can vary per batch |

| Processing Control | Limited control after blending | Better control over individual tobaccos |

| Cost Efficiency | Lower cost, bulk processing | Higher cost due to separate processing |

| Quality Assurance | Challenging to identify leaf quality variances | Easier to monitor and adjust quality |

| Typical Use | Used in mass-market cigarette production | Preferred in premium tobacco products |

Introduction to Pre-Blending and Post-Blending

Pre-blending involves mixing all raw ingredients thoroughly before the production process, ensuring homogeneity and consistent quality throughout the batch. Post-blending occurs after initial processing, allowing for adjustments based on product characteristics or final specifications to optimize performance or taste. Choosing between pre-blending and post-blending impacts manufacturing efficiency, ingredient utilization, and final product uniformity.

Definitions and Core Concepts

Pre-blending involves mixing ingredients thoroughly before processing to ensure uniform consistency and accurate distribution of components, enhancing product quality and production efficiency. Post-blending refers to the addition of ingredients after the initial processing stage, allowing for customization and adjustment of the final product characteristics. Understanding these core concepts helps you optimize manufacturing workflows and achieve desired product specifications in industries like food, pharmaceuticals, and plastics.

Key Differences Between Pre-Blending and Post-Blending

Pre-blending involves mixing raw materials before the manufacturing process, ensuring consistent composition and uniform quality in the final product. Post-blending occurs after initial processing, allowing for adjustments to achieve desired product specifications and flexibility in production. Key differences include timing, control over ingredient distribution, and impact on processing efficiency.

Advantages of Pre-Blending

Pre-blending offers consistent ingredient distribution, which enhances product uniformity and quality control throughout manufacturing. It reduces processing time and labor costs by minimizing separate ingredient handling, improving overall operational efficiency. Your production benefits from decreased contamination risk and improved traceability with pre-blended materials.

Benefits of Post-Blending

Post-blending enhances flexibility by allowing precise ingredient adjustments after initial mixing, improving product consistency and quality control. It reduces waste and inventory costs by enabling customization of blends for specific customer needs without reformulating the entire batch. This method also supports faster turnaround times in production, accommodating last-minute changes efficiently.

Challenges in Pre-Blending Processes

Pre-blending processes face challenges such as maintaining uniform ingredient distribution and controlling moisture content to prevent clumping or segregation. Inconsistent particle size and density differences among raw materials can result in uneven blends, impacting product quality and process efficiency. Additionally, managing dust generation and ensuring precise dosing during pre-blending require advanced equipment and strict quality control measures.

Common Issues in Post-Blending Operations

Post-blending operations often encounter challenges such as inconsistent ingredient distribution, leading to variable product quality and reduced homogeneity. Equipment limitations and inadequate mixing times can cause segregation or ingredient stratification after the blend is prepared. These issues result in increased rework, waste, and potential compliance risks in industries requiring precise formulation control.

Industry Applications of Pre-Blending and Post-Blending

Pre-blending is widely used in industries such as pharmaceuticals and food manufacturing to ensure consistent ingredient distribution and streamline production by mixing raw materials before processing. Post-blending finds applications in chemical and plastics industries where precise final adjustments of properties like color, additives, or performance enhancers are needed after initial product formation. Your choice between pre-blending and post-blending depends on the specific quality control requirements and process flow complexity in the targeted industrial application.

Choosing the Right Blending Method

Choosing the right blending method depends on the specific product formulation and manufacturing process requirements. Pre-blending ensures uniform distribution of dry ingredients before further processing, enhancing consistency and reducing segregation risks. Post-blending offers flexibility by mixing ingredients after initial processing, allowing for ingredient adjustments and improved customization.

Future Trends in Blending Technologies

Future trends in blending technologies emphasize enhanced automation and real-time monitoring to optimize pre-blending and post-blending processes. Advances in AI-driven predictive analytics improve ingredient consistency and reduce material waste by precisely controlling blend ratios before and after mixing. Integration of IoT sensors facilitates continuous quality assessment, enabling dynamic adjustments that enhance efficiency and product uniformity in industrial blending applications.

pre-blending vs post-blending Infographic

libmatt.com

libmatt.com