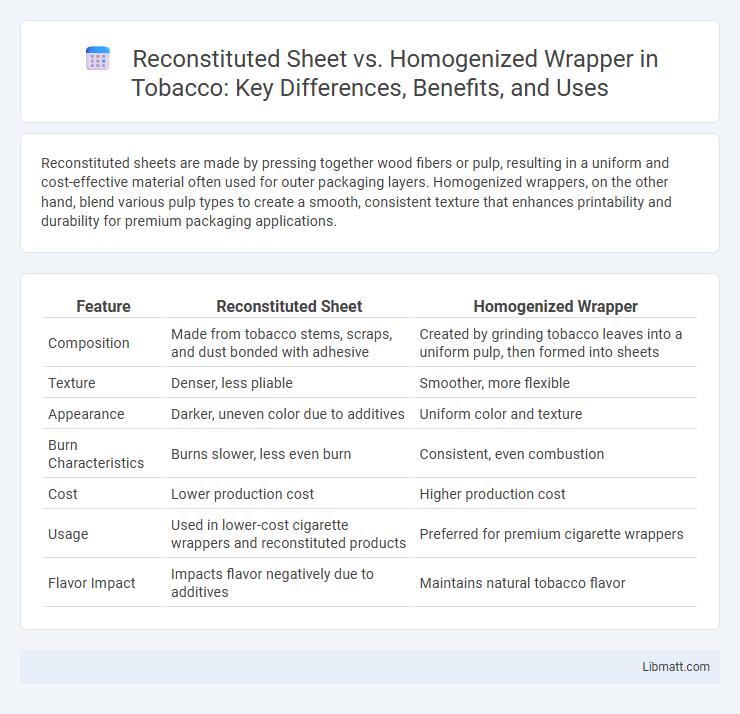

Reconstituted sheets are made by pressing together wood fibers or pulp, resulting in a uniform and cost-effective material often used for outer packaging layers. Homogenized wrappers, on the other hand, blend various pulp types to create a smooth, consistent texture that enhances printability and durability for premium packaging applications.

Table of Comparison

| Feature | Reconstituted Sheet | Homogenized Wrapper |

|---|---|---|

| Composition | Made from tobacco stems, scraps, and dust bonded with adhesive | Created by grinding tobacco leaves into a uniform pulp, then formed into sheets |

| Texture | Denser, less pliable | Smoother, more flexible |

| Appearance | Darker, uneven color due to additives | Uniform color and texture |

| Burn Characteristics | Burns slower, less even burn | Consistent, even combustion |

| Cost | Lower production cost | Higher production cost |

| Usage | Used in lower-cost cigarette wrappers and reconstituted products | Preferred for premium cigarette wrappers |

| Flavor Impact | Impacts flavor negatively due to additives | Maintains natural tobacco flavor |

Introduction to Reconstituted Sheets and Homogenized Wrappers

Reconstituted sheets are manufactured by breaking down tobacco leaves into fibers, then reforming them into uniform sheets, allowing for consistent burn and flavor in cigar production. Homogenized wrappers consist of tobacco fibers blended with adhesive agents, creating a stable and pliable leaf cover that enhances the cigar's structural integrity. Understanding the distinct processing methods of these wrappers can help you select the ideal option for desired aesthetics and smoking experience.

Definition and Composition of Reconstituted Sheets

Reconstituted sheets are made by breaking down tobacco leaves into fibers, then mixing these fibers with adhesives and additives to form a thin, uniform sheet that can be cut into wrappers. This process allows manufacturers to recycle tobacco scraps and control the consistency and quality of the wrapper more precisely than natural leaf wrappers. Your choice between reconstituted sheet and homogenized wrapper impacts the flavor, burn rate, and overall smoking experience due to the differences in composition and processing methods.

What Are Homogenized Wrappers?

Homogenized wrappers are cigar wrappers made from tobacco pulp that has been processed to create a uniform, smooth leaf-like sheet. Unlike reconstituted sheets formed from shredded tobacco, homogenized wrappers maintain consistent moisture and burn qualities due to their controlled production. Your choice between these wrappers can affect flavor, combustion, and overall cigar experience.

Manufacturing Processes: Reconstituted vs. Homogenized

Reconstituted wrappers are produced by shredding tobacco leaves, adding adhesives, and pressing the material into uniform sheets, allowing for consistent texture and controlled nicotine content. Homogenized wrappers involve grinding tobacco into a pulp, mixing it with binders and fillers, and then forming it into sheets through a wet-laid process, resulting in smooth, uniform appearance with enhanced burn qualities. Both manufacturing techniques optimize wrapper quality, but reconstituted sheets emphasize structural integrity while homogenized wrappers prioritize visual consistency and uniform combustion.

Key Material Differences

Reconstituted sheets are made by blending tobacco scraps and stems into a pulp, resulting in a uniform and lower-cost wrapper with consistent thickness and color. Homogenized wrappers consist of tobacco fibers bonded together with adhesives, offering increased strength and elasticity, which reduces tearing and improves manufacturability. Key material differences include texture, tensile strength, and moisture retention, with reconstituted sheets providing a smoother surface and homogenized wrappers offering greater durability for cigar wrappers.

Aesthetic and Sensory Characteristics

Reconstituted sheets offer a uniform texture and color, providing a consistent aesthetic appeal ideal for premium products, while homogenized wrappers present a more natural, varied appearance with subtle veins and color gradients. Sensory characteristics differ as reconstituted sheets tend to burn evenly but may lack the natural leaf aroma and subtle flavors found in homogenized wrappers, which deliver a richer, more authentic smoking experience. Your choice depends on whether you prioritize visual perfection and uniformity or the nuanced sensory traits associated with natural leaf wrappers.

Durability and Functional Performance

Reconstituted sheets offer consistent durability with improved tensile strength and uniform thickness, enhancing their resistance to tearing and abrasion during manufacturing and handling. Homogenized wrappers provide excellent functional performance by ensuring even moisture distribution and burn rate, resulting in a smoother smoking experience. Both materials balance durability and performance, but reconstituted sheets excel in mechanical resilience, while homogenized wrappers optimize combustion properties.

Environmental Impact and Sustainability

Reconstituted sheets are made by blending tobacco leaf scraps and stems, reducing waste and promoting sustainability through resource optimization. Homogenized wrappers use a tobacco pulp and adhesive mixture, which requires more processing and energy, resulting in a higher environmental footprint. Your choice between these wrappers influences the overall environmental impact of tobacco products, with reconstituted sheets offering a more eco-friendly option due to their efficient use of raw materials.

Cost Comparison: Which is More Economical?

Reconstituted sheets generally offer a more economical option compared to homogenized wrappers due to lower material and production costs. Your choice depends on budget constraints and desired wrapper quality, as reconstituted sheets often use cheaper fiber blends, while homogenized wrappers provide smoother texture at a higher price. Manufacturers balance cost savings against consumer preferences when selecting between these two wrapper types.

Choosing the Right Option: Reconstituted Sheet or Homogenized Wrapper

Choosing the right option between a reconstituted sheet and a homogenized wrapper depends on the desired flavor, texture, and burn characteristics of your cigar. Reconstituted sheets offer a uniform appearance and consistent burn, ideal for mass production and cost-efficiency, while homogenized wrappers provide better flexibility and strength, preserving the tobacco's natural taste. Your preference for a smoother smoking experience or a more authentic tobacco flavor will guide the decision between these two popular cigar wrapper materials.

Reconstituted sheet vs homogenized wrapper Infographic

libmatt.com

libmatt.com