Rotocut blades feature a circular design that enables smooth, continuous slicing ideal for cutting meats and vegetables quickly, while flat cut blades provide a straight, precise edge perfect for delicate tasks like trimming or fine slicing. Your choice depends on whether you prioritize speed and efficiency with rotocut or accuracy and control with flat cut.

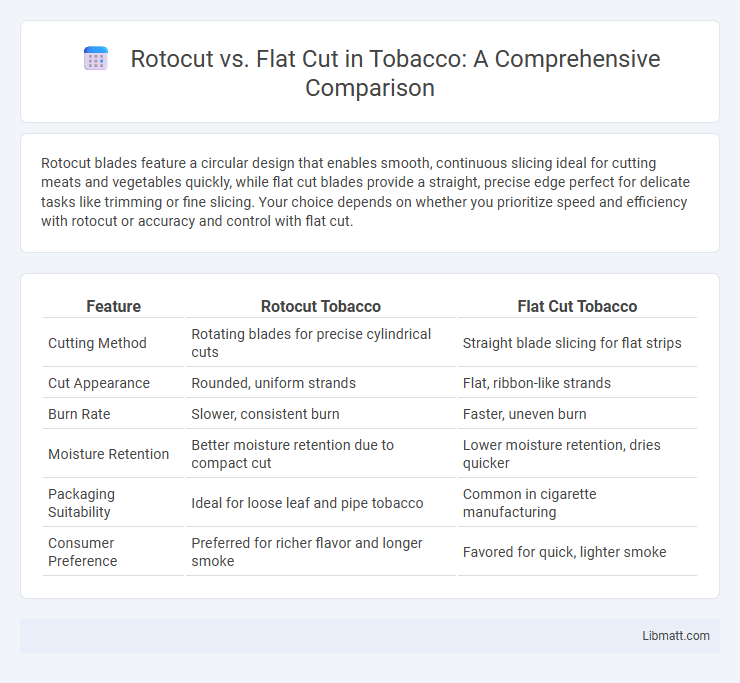

Table of Comparison

| Feature | Rotocut Tobacco | Flat Cut Tobacco |

|---|---|---|

| Cutting Method | Rotating blades for precise cylindrical cuts | Straight blade slicing for flat strips |

| Cut Appearance | Rounded, uniform strands | Flat, ribbon-like strands |

| Burn Rate | Slower, consistent burn | Faster, uneven burn |

| Moisture Retention | Better moisture retention due to compact cut | Lower moisture retention, dries quicker |

| Packaging Suitability | Ideal for loose leaf and pipe tobacco | Common in cigarette manufacturing |

| Consumer Preference | Preferred for richer flavor and longer smoke | Favored for quick, lighter smoke |

Introduction to Rotocut and Flat Cut Technologies

Rotocut technology utilizes rotary blades that rotate at high speed to achieve smooth and precise cuts, ideal for applications requiring minimal material deformation and clean edges. Flat cut systems employ stationary blades that move linearly against the material, providing robust cutting suitable for thicker or tougher materials where consistent depth and pressure are essential. Both technologies serve distinct industrial applications, with Rotocut excelling in speed and finish quality, while flat cut offers durability and cutting strength for varied material types.

Key Differences Between Rotocut and Flat Cut

Rotocut uses a rotating cylindrical blade to achieve high-speed, continuous slicing, ideal for uniform and precise cuts in large-scale production. Flat cut employs a reciprocating straight blade, providing more controlled, thicker slices suitable for delicate or varied cutting tasks. Understanding these differences helps optimize your cutting process based on speed, precision, and material type.

How Rotocut Systems Work

Rotocut systems utilize rotating blades that continuously spin to slice materials with high precision and speed, making them ideal for applications requiring clean, straight cuts on various substrates. The rotating mechanism reduces friction and heat buildup, enhancing blade longevity and ensuring smooth edges without deformation. This technology outperforms flat cut systems in efficiency and consistency, especially on thicker or fibrous materials.

The Process Behind Flat Cut Machines

Flat cut machines utilize a precise margin cutting process where the blade moves in a straight, linear motion to trim the margins around digital prints and photographs. This method ensures clean, accurate edges by following predefined crop marks or templates, minimizing waste and preserving image integrity. The process is favored for its efficiency in producing uniform, high-quality cuts on various materials such as paper, cardboard, and thin plastics.

Advantages of Rotocut Cutting

Rotocut cutting offers higher precision and cleaner cuts compared to flat cut methods, making it ideal for intricate designs and delicate materials. This technique reduces material waste and increases production speed by minimizing cuts and maximizing surface area utilization. Your projects benefit from improved edge quality and consistent accuracy, enhancing overall efficiency and finish quality.

Benefits of Flat Cut Methods

Flat cut methods provide enhanced material efficiency by minimizing kerf loss compared to rotary cutting, resulting in more usable product per sheet. This technique delivers precise, clean edges ideal for materials requiring exact dimensions and high-quality finishes. Flat cutting also allows for consistent thickness control, improving overall manufacturing accuracy and reducing waste.

Typical Applications for Rotocut vs Flat Cut

Rotocut tools excel in high-speed machining and roughing operations, making them ideal for applications involving heavy metal removal and large-scale production runs in industries such as automotive and aerospace. Flat cut tools are preferred for precision finishing tasks, fine detailing, and applications requiring smooth surface finishes, commonly utilized in mold making, tool fabrication, and electronics manufacturing. Choosing between rotocut and flat cut depends on the specific machining requirements, material hardness, and desired surface quality.

Factors to Consider When Choosing Between Rotocut and Flat Cut

When choosing between rotocut and flat cut methods, consider factors such as material type, thickness, and desired edge quality. Rotocut excels in precision and speed for cylindrical or tubular materials, while flat cut is ideal for flat sheets requiring clean, straight edges. Your specific application requirements and production volume will determine the most efficient and cost-effective cutting technique.

Cost Comparison: Rotocut vs Flat Cut

Rotocut offers a higher initial investment compared to flat cut due to advanced machinery and precision technology, but it reduces material waste and operational costs over time. Flat cut methods are generally more affordable upfront and suitable for smaller production runs, though they may incur higher labor expenses and lower efficiency. Your choice depends on balancing initial budget constraints with long-term cost savings in production volume and quality.

Which Cutting Solution is Best for Your Needs?

Rotocut blades provide high-speed, smooth cuts ideal for precision tasks and repetitive cutting, making them perfect for fabric, felt, or leather. Flat cut blades offer sharper edges designed for detailed, straight cuts and better control over intricate shapes, often preferred in crafts requiring accuracy. Assess your project's material type, complexity, and volume to determine which cutting solution suits your specific needs best.

Rotocut vs flat cut Infographic

libmatt.com

libmatt.com