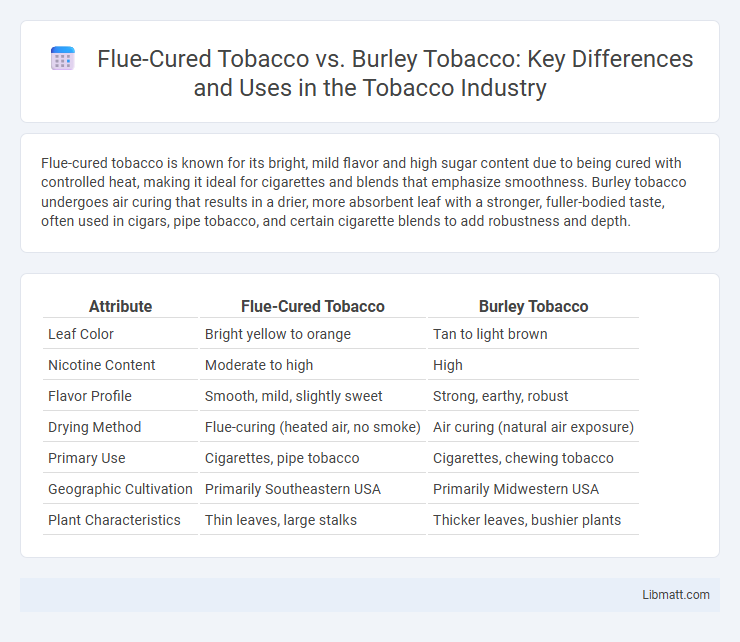

Flue-cured tobacco is known for its bright, mild flavor and high sugar content due to being cured with controlled heat, making it ideal for cigarettes and blends that emphasize smoothness. Burley tobacco undergoes air curing that results in a drier, more absorbent leaf with a stronger, fuller-bodied taste, often used in cigars, pipe tobacco, and certain cigarette blends to add robustness and depth.

Table of Comparison

| Attribute | Flue-Cured Tobacco | Burley Tobacco |

|---|---|---|

| Leaf Color | Bright yellow to orange | Tan to light brown |

| Nicotine Content | Moderate to high | High |

| Flavor Profile | Smooth, mild, slightly sweet | Strong, earthy, robust |

| Drying Method | Flue-curing (heated air, no smoke) | Air curing (natural air exposure) |

| Primary Use | Cigarettes, pipe tobacco | Cigarettes, chewing tobacco |

| Geographic Cultivation | Primarily Southeastern USA | Primarily Midwestern USA |

| Plant Characteristics | Thin leaves, large stalks | Thicker leaves, bushier plants |

Introduction to Flue-Cured and Burley Tobacco

Flue-cured tobacco, primarily grown in the southeastern United States, is characterized by its bright color and mild, sweet flavor resulting from the heat curing process. Burley tobacco, commonly cultivated in the midwestern regions, undergoes air curing, producing a light brown leaf with a thicker texture and a more robust, earthy taste. Understanding the distinctions between flue-cured and Burley tobacco helps you select the right variety for your specific cigarette blends or chewing tobacco products.

Historical Origins and Global Cultivation

Flue-cured tobacco, primarily derived from Nicotiana tabacum, originated in the southeastern United States during the early 19th century and is cultivated extensively in regions like North Carolina and Virginia due to its bright, mild flavor achieved through high-temperature curing. Burley tobacco, also a variety of Nicotiana tabacum, traces its roots to central Kentucky and Tennessee, known for its air-cured process producing a light, airy leaf favored in cigarette blends globally. Currently, flue-cured tobacco dominates production in countries such as the United States, Zimbabwe, and Brazil, while Burley tobacco sees widespread cultivation in the U.S., Malawi, and Tanzania, reflecting diverse agricultural practices and market preferences.

Distinctive Curing Processes Explained

Flue-cured tobacco undergoes a controlled heat-curing process using flues or pipes to circulate heat without smoke, preserving bright orange to yellow leaf color ideal for cigarette production. Burley tobacco is air-cured by hanging leaves in well-ventilated barns, allowing natural drying that produces a light brown, porous leaf suited for flavored and cigarette blends. These distinctive curing methods significantly impact the chemical composition, combustion characteristics, and flavor profiles of each tobacco type.

Leaf Characteristics and Appearance

Flue-cured tobacco features bright golden to orange leaves with a smooth, pliable texture due to curing at controlled temperatures, enhancing sweetness and aroma. Burley tobacco leaves are thicker, broader, and brownish with a rougher texture, cured through air drying that emphasizes a milder taste with higher nicotine content. Understanding these leaf characteristics helps you select tobacco perfectly suited for your flavor and curing preferences.

Chemical Composition and Nicotine Content

Flue-cured tobacco contains higher sugar levels and lower nicotine content compared to Burley tobacco, which is characterized by its lower sugar and higher nicotine concentration. The chemical composition of flue-cured leaves includes more sugars and tar, influencing a sweeter flavor profile, while Burley tobacco's higher alkaloid content provides a stronger, more robust taste. Understanding these differences helps you select the type of tobacco best suited to your preferences or product requirements.

Flavor Profiles and Smoking Experience

Flue-cured tobacco offers a mild, sweet flavor with a smooth, light smoke that many prefer for its subtle sweetness and low bitterness. Burley tobacco provides a richer, more robust taste characterized by earthy and nutty undertones, creating a fuller-bodied smoking experience. Your choice between these tobaccos can significantly influence the flavor intensity and smoothness of your smoke, depending on your personal preference.

Common Uses in Tobacco Products

Flue-cured tobacco is primarily used in cigarettes due to its mild, sweet flavor and light, yellowish color after curing. Burley tobacco is favored in pipe tobacco, cigars, and chewing tobacco because of its robust, smoky flavor and higher nicotine content. Both types contribute distinct flavor profiles and burning characteristics that influence the final tobacco product quality.

Market Demand and Economic Importance

Flue-cured tobacco dominates global markets due to its mild flavor and versatility in cigarette production, driving substantial economic value in countries like the United States, Brazil, and Zimbabwe. Burley tobacco, prized for its light air-cured qualities, holds significant demand in North America and parts of Europe, influencing regional economies through specialized cigarette blends and chewing tobacco products. Market demand for flue-cured tobacco consistently outpaces burley, impacting pricing, export revenues, and farming practices in major tobacco-producing regions.

Environmental Impact of Cultivation

Flue-cured tobacco cultivation generally requires higher energy input for curing, contributing to greater carbon emissions compared to Burley tobacco, which uses air-curing methods with lower energy demands. Flue-cured tobacco farming often involves intensive irrigation and chemical use, leading to significant water consumption and soil degradation. Your choice between these tobacco types can impact environmental sustainability based on local water availability and energy resources.

Future Trends and Industry Innovations

Flue-cured tobacco is expected to benefit from advances in curing technologies that enhance leaf quality and reduce production costs, meeting growing demand in international cigarette markets. Burley tobacco innovations focus on genetic improvements for disease resistance and lower nicotine levels to address health regulations and diversify product applications. Both varieties are seeing increased integration of precision agriculture and sustainable farming practices to optimize yields and reduce environmental impact in the evolving tobacco industry.

Flue-cured tobacco vs Burley tobacco Infographic

libmatt.com

libmatt.com