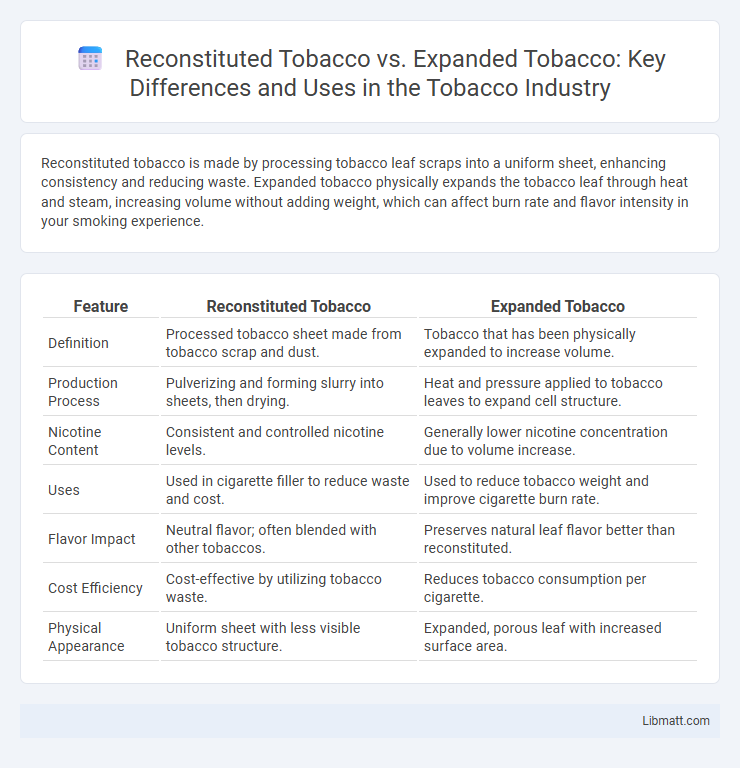

Reconstituted tobacco is made by processing tobacco leaf scraps into a uniform sheet, enhancing consistency and reducing waste. Expanded tobacco physically expands the tobacco leaf through heat and steam, increasing volume without adding weight, which can affect burn rate and flavor intensity in your smoking experience.

Table of Comparison

| Feature | Reconstituted Tobacco | Expanded Tobacco |

|---|---|---|

| Definition | Processed tobacco sheet made from tobacco scrap and dust. | Tobacco that has been physically expanded to increase volume. |

| Production Process | Pulverizing and forming slurry into sheets, then drying. | Heat and pressure applied to tobacco leaves to expand cell structure. |

| Nicotine Content | Consistent and controlled nicotine levels. | Generally lower nicotine concentration due to volume increase. |

| Uses | Used in cigarette filler to reduce waste and cost. | Used to reduce tobacco weight and improve cigarette burn rate. |

| Flavor Impact | Neutral flavor; often blended with other tobaccos. | Preserves natural leaf flavor better than reconstituted. |

| Cost Efficiency | Cost-effective by utilizing tobacco waste. | Reduces tobacco consumption per cigarette. |

| Physical Appearance | Uniform sheet with less visible tobacco structure. | Expanded, porous leaf with increased surface area. |

Introduction to Reconstituted and Expanded Tobacco

Reconstituted tobacco is a processed form of tobacco made by combining tobacco dust, stems, and fines into a sheet, providing uniformity and consistent burning characteristics. Expanded tobacco involves treating tobacco leaves with gases or chemicals to increase volume and reduce density, enhancing flavor and reducing filler content in cigarettes. Both types optimize tobacco use by improving smoking quality and manufacturing efficiency in the cigarette industry.

What is Reconstituted Tobacco?

Reconstituted tobacco is a product made by combining tobacco leaf scraps, stems, and dust into a uniform sheet using a binder and water, creating a consistent and efficient material for cigarette manufacturing. This process maximizes the use of tobacco by recycling smaller tobacco particles that would otherwise be discarded. Reconstituted tobacco offers controlled nicotine delivery and burning characteristics, contributing to cost-effective tobacco products.

What is Expanded Tobacco?

Expanded tobacco is a processed form of tobacco that undergoes treatment to increase its volume and reduce density by introducing steam or chemicals, resulting in a lighter yet voluminous product. This expansion process enhances burning properties and reduces the amount of tobacco needed in cigarette manufacturing, optimizing cost and smoke delivery. Expanded tobacco maintains essential flavor components while contributing to improved combustion and smoke consistency compared to traditional leaf tobacco.

Key Differences Between Reconstituted and Expanded Tobacco

Reconstituted tobacco is produced by combining tobacco leaf scraps with additives to form a uniform sheet, enhancing burn consistency and flavor control, while expanded tobacco undergoes a physical expansion process that increases volume and reduces nicotine content. The key differences lie in their manufacturing techniques: reconstituted tobacco utilizes a blending and pressing method, whereas expanded tobacco uses heat and gas to puff the leaves. Your choice between these types affects cigarette characteristics, including taste, burn rate, and nicotine delivery.

Production Processes: Reconstituted vs Expanded Tobacco

Reconstituted tobacco is produced by processing tobacco scraps, stems, and dust into a homogeneous sheet using water, binders, and often flavor additives, ensuring uniformity and consistent burning properties. Expanded tobacco, on the other hand, is created by injecting steam or gas into tobacco leaves during curing or processing, causing the leaves to increase in volume and reduce density while preserving natural leaf structure. Understanding these distinct production processes helps optimize tobacco usage in your product formulation for desired flavor and combustion characteristics.

Ingredient Composition and Quality Comparison

Reconstituted tobacco is made from finely processed tobacco leaf scraps, stems, and stalks bound together with adhesives and flavor additives, providing uniformity and consistency in cigarette blends. Expanded tobacco undergoes a physical expansion process that reduces density while retaining whole leaf structure, often preserving more natural tobacco flavors and a smoother smoking experience. Your choice between these tobaccos depends on desired ingredient quality and blend characteristics, with reconstituted tobacco offering economic efficiency and expanded tobacco delivering enhanced flavor and texture.

Impact on Cigarette Manufacturing

Reconstituted tobacco enhances cigarette manufacturing by providing a uniform and consistent filler that improves blend control and reduces waste, allowing for precise flavor and nicotine delivery. Expanded tobacco reduces cigarette weight and increases fill volume without compromising taste, which helps manufacturers meet regulatory weight restrictions and lower production costs. Both types optimize the manufacturing process by improving operational efficiency and product consistency in cigarette production.

Flavor, Aroma, and Consumer Experience

Reconstituted tobacco offers a consistent flavor and smooth aroma by blending tobacco leaf particles, enhancing burn control and uniformity for consumers. Expanded tobacco provides a lighter, fuller-bodied taste with increased volume, delivering a richer aroma and a more robust smoking experience. Both types influence flavor complexity and sensory satisfaction, shaping distinct consumer preferences in tobacco products.

Health Implications and Regulatory Considerations

Reconstituted tobacco undergoes processing that concentrates tobacco-specific nitrosamines (TSNAs), which are known carcinogens, potentially increasing health risks compared to expanded tobacco, which is mechanically treated to reduce tobacco mass and smoke constituents. Regulatory bodies often impose stricter limits and testing requirements on reconstituted tobacco due to its higher levels of harmful chemicals, whereas expanded tobacco may face fewer restrictions because it can lower tar and nicotine yields in cigarettes. Understanding these differences is critical for compliance with tobacco product standards and mitigating public health risks associated with tobacco use.

Future Trends in Tobacco Blending Technologies

Future trends in tobacco blending technologies emphasize sustainable practices, with reconstituted tobacco gaining traction due to its ability to utilize tobacco by-products and reduce waste. Expanded tobacco remains valued for enhancing smoking experience by increasing volume while lowering tar and nicotine content, supporting regulatory compliance. Innovations integrating artificial intelligence and precision blending are expected to optimize the balance between flavor, cost, and health considerations in both reconstituted and expanded tobacco production.

Reconstituted tobacco vs Expanded tobacco Infographic

libmatt.com

libmatt.com