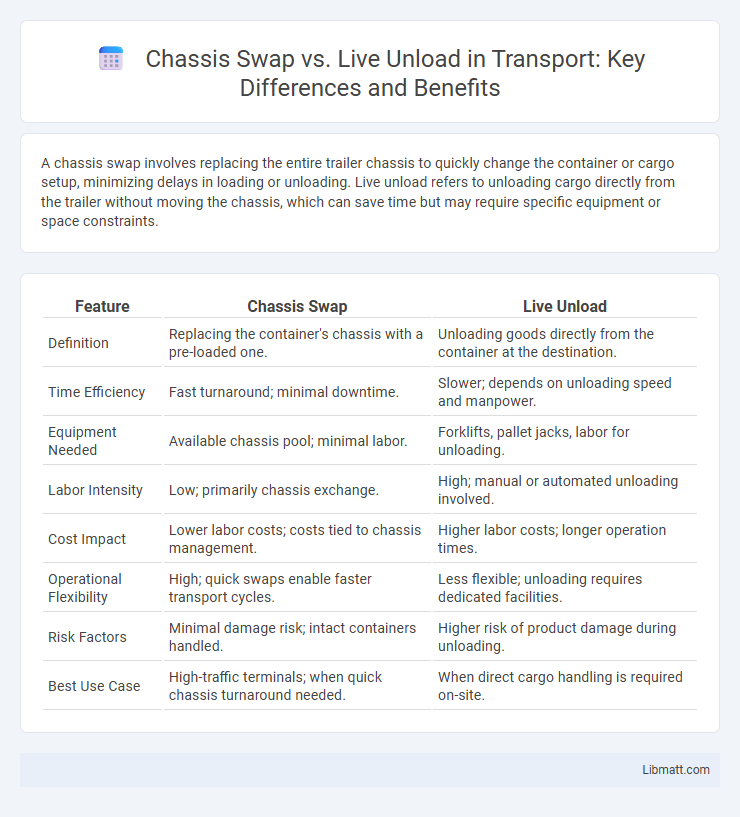

A chassis swap involves replacing the entire trailer chassis to quickly change the container or cargo setup, minimizing delays in loading or unloading. Live unload refers to unloading cargo directly from the trailer without moving the chassis, which can save time but may require specific equipment or space constraints.

Table of Comparison

| Feature | Chassis Swap | Live Unload |

|---|---|---|

| Definition | Replacing the container's chassis with a pre-loaded one. | Unloading goods directly from the container at the destination. |

| Time Efficiency | Fast turnaround; minimal downtime. | Slower; depends on unloading speed and manpower. |

| Equipment Needed | Available chassis pool; minimal labor. | Forklifts, pallet jacks, labor for unloading. |

| Labor Intensity | Low; primarily chassis exchange. | High; manual or automated unloading involved. |

| Cost Impact | Lower labor costs; costs tied to chassis management. | Higher labor costs; longer operation times. |

| Operational Flexibility | High; quick swaps enable faster transport cycles. | Less flexible; unloading requires dedicated facilities. |

| Risk Factors | Minimal damage risk; intact containers handled. | Higher risk of product damage during unloading. |

| Best Use Case | High-traffic terminals; when quick chassis turnaround needed. | When direct cargo handling is required on-site. |

Introduction to Chassis Swap and Live Unload

Chassis swap and live unload are critical logistics strategies used in container transportation to improve operational efficiency at ports and distribution centers. Chassis swap involves replacing an empty chassis with a loaded one, enabling trucks to quickly transport containers without waiting for loading or unloading processes. Live unload refers to directly unloading cargo from a container onto a truck or storage facility, minimizing container dwell time and reducing overall turnaround time.

Definition of Chassis Swap

Chassis swap involves replacing the trailer's chassis with another to expedite delivery and reduce waiting times at shipping terminals. This process allows Your cargo to remain secure while the chassis is switched, optimizing logistics efficiency. Unlike live unload, chassis swap does not require unloading the contents before the chassis exchange.

What is Live Unload?

Live unload refers to the process where a truck driver remains with the vehicle while cargo is being unloaded directly from the trailer, eliminating the need for a chassis swap. This method improves efficiency by reducing wait times and minimizing handling, making it ideal for destinations with limited dock space or specific equipment constraints. Live unload ensures timely delivery and better cargo security compared to traditional chassis swaps that involve detaching and replacing trailers.

Key Differences Between Chassis Swap and Live Unload

Chassis swap involves exchanging one trailer chassis for another to facilitate cargo transfer, while live unload refers to unloading cargo directly from the trailer without moving it. Chassis swap is typically faster and minimizes yard storage needs but requires compatible chassis availability and coordination. Live unload allows for direct access to goods, reducing handling steps but often demands more time, space, and labor at the unloading site.

Pros and Cons of Chassis Swap

Chassis swap offers increased efficiency by allowing trucks to quickly exchange trailers without waiting for cargo unloading, reducing idle time and improving fleet utilization. However, this method can require a larger inventory of chassis, leading to higher upfront costs and increased maintenance responsibilities. Your operation benefits from faster turnaround times, but careful management is necessary to balance the expenses and logistical complexity of maintaining multiple chassis units.

Advantages and Disadvantages of Live Unload

Live unload offers the advantage of faster turnaround times by unloading cargo directly at the delivery site without detaching the chassis, reducing downtime and improving logistics efficiency. However, it requires specialized equipment and trained personnel, which can increase operational costs and limit its application to facilities equipped for live unloading. Your choice between a chassis swap and live unload depends on your facility's infrastructure, cargo type, and overall delivery strategy.

Operational Impact on Logistics and Supply Chain

Chassis swap significantly enhances operational efficiency by reducing wait times in freight yards, enabling faster turnaround and improving asset utilization across the supply chain. Live unload requires coordination of labor and equipment on-site, potentially causing delays and increasing variability in delivery schedules. Optimizing your logistics with chassis swap can streamline workflows, lower transportation costs, and improve overall supply chain responsiveness.

Cost Comparison: Chassis Swap vs Live Unload

Chassis swap typically incurs lower labor costs due to faster turnaround times and reduced wait periods at terminals, making it a cost-effective option for shipping companies. Live unload involves higher expenses related to forklift operation, dock labor, and potential demurrage fees, increasing overall operational costs. Evaluating port fees and equipment availability is essential for accurate cost comparison between chassis swap and live unload methods.

Situational Use Cases for Each Method

Chassis swap is ideal for port terminals and intermodal yards where quick turnaround and minimized dwell times are critical, allowing trucks to detach empty chassis and pick up loaded units seamlessly. Live unload is preferred in warehouse or distribution center environments where cargo handling requires direct access to containers for unloading or loading without changing chassis. Choosing between chassis swap and live unload depends on operational priorities such as speed, equipment availability, and cargo handling needs.

Choosing the Right Solution for Your Operations

Selecting between chassis swap and live unload depends on operational efficiency and cargo handling needs. Chassis swap maximizes equipment utilization by quickly exchanging trailers, minimizing downtime during container movements. Live unload suits facilities requiring direct cargo transfer from container to dock, enhancing flexibility but often increasing handling time and labor costs.

chassis swap vs live unload Infographic

libmatt.com

libmatt.com