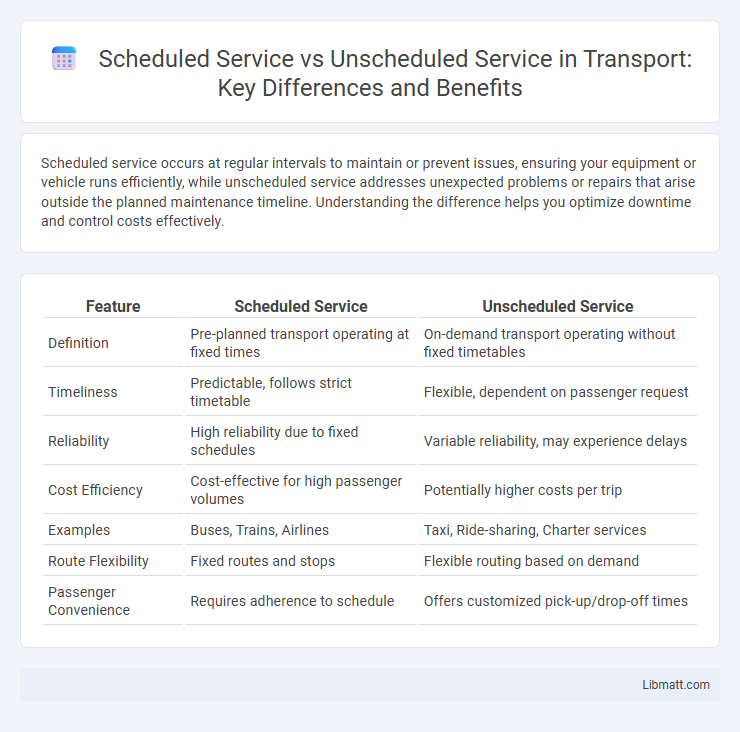

Scheduled service occurs at regular intervals to maintain or prevent issues, ensuring your equipment or vehicle runs efficiently, while unscheduled service addresses unexpected problems or repairs that arise outside the planned maintenance timeline. Understanding the difference helps you optimize downtime and control costs effectively.

Table of Comparison

| Feature | Scheduled Service | Unscheduled Service |

|---|---|---|

| Definition | Pre-planned transport operating at fixed times | On-demand transport operating without fixed timetables |

| Timeliness | Predictable, follows strict timetable | Flexible, dependent on passenger request |

| Reliability | High reliability due to fixed schedules | Variable reliability, may experience delays |

| Cost Efficiency | Cost-effective for high passenger volumes | Potentially higher costs per trip |

| Examples | Buses, Trains, Airlines | Taxi, Ride-sharing, Charter services |

| Route Flexibility | Fixed routes and stops | Flexible routing based on demand |

| Passenger Convenience | Requires adherence to schedule | Offers customized pick-up/drop-off times |

Introduction to Scheduled vs Unscheduled Service

Scheduled service involves regular, planned maintenance activities designed to prevent equipment failure and ensure optimal performance, such as oil changes and inspections based on manufacturer guidelines. Unscheduled service occurs unexpectedly, addressing urgent repairs or breakdowns that disrupt normal operation and may result in higher costs and extended downtime. Understanding the difference helps you plan maintenance budgets effectively and minimize avoidable interruptions.

Defining Scheduled Service

Scheduled service refers to regular, planned maintenance performed at predefined intervals based on time or usage metrics, ensuring optimal performance and preventing unexpected breakdowns. This proactive approach includes tasks such as oil changes, filter replacements, and system inspections to maintain your vehicle or equipment's reliability. Consistent adherence to scheduled service extends lifespan and reduces long-term repair costs by addressing potential issues early.

What is Unscheduled Service?

Unscheduled service refers to maintenance or repairs performed unexpectedly due to equipment failure, breakdowns, or urgent malfunctions that disrupt normal operations. This type of service addresses immediate issues without prior planning, often causing downtime and increased operational costs. Businesses rely on quick response times and skilled technicians to minimize the impact of unscheduled service events.

Key Differences Between Scheduled and Unscheduled Service

Scheduled service involves routine maintenance tasks performed at predetermined intervals to prevent breakdowns and extend equipment lifespan. Unscheduled service occurs in response to unexpected failures or malfunctions, requiring immediate attention to restore functionality. Understanding these key differences helps you optimize maintenance strategies, reduce downtime, and manage operational costs effectively.

Advantages of Scheduled Service

Scheduled service ensures consistent maintenance, preventing unexpected failures and extending equipment lifespan. It allows for better resource allocation and reduces downtime by addressing issues before they escalate. Regularly planned inspections enhance safety compliance and improve overall operational efficiency.

Benefits of Unscheduled Service

Unscheduled service offers immediate response to unexpected equipment breakdowns, minimizing downtime and preventing costly operational delays. It ensures rapid troubleshooting and repairs by expert technicians, maintaining system reliability and safety. This flexibility supports continuous production and reduces long-term maintenance expenses by addressing issues before they escalate.

Common Challenges With Each Service Type

Scheduled service often faces challenges like strict adherence to timelines and potential disruption to daily operations, while unscheduled service can lead to unexpected downtime and higher emergency repair costs. Your maintenance team might struggle with resource allocation when balancing planned maintenance with urgent repairs. Both service types require effective communication and coordination to minimize operational impact and ensure equipment reliability.

Industry Applications: When to Use Scheduled or Unscheduled Service

Scheduled service is essential in industries like manufacturing and aviation, where routine maintenance prevents costly downtime and ensures safety compliance. Unscheduled service is critical in industries such as healthcare and IT, where unexpected equipment failures require immediate repair to avoid operational disruptions. You can maximize your asset reliability by understanding when to apply scheduled maintenance for prevention and unscheduled service for urgent problem-solving.

Cost Implications of Scheduled vs Unscheduled Service

Scheduled service typically incurs lower overall costs due to planned maintenance that prevents major breakdowns and extends equipment lifespan. Unscheduled service often leads to higher expenses caused by emergency repairs, unexpected downtime, and potential collateral damage. Proactively investing in scheduled service reduces the risk of costly disruptions and improves long-term operational efficiency.

Choosing the Right Service Model for Your Needs

Scheduled service ensures timely maintenance and predictable costs by following manufacturer-recommended intervals, which reduces the risk of unexpected breakdowns. Unscheduled service addresses issues as they arise, offering flexibility for urgent repairs but potentially leading to higher expenses and downtime. Evaluating the frequency of use, budget constraints, and equipment criticality helps determine whether scheduled or unscheduled service best aligns with operational needs.

scheduled service vs unscheduled service Infographic

libmatt.com

libmatt.com