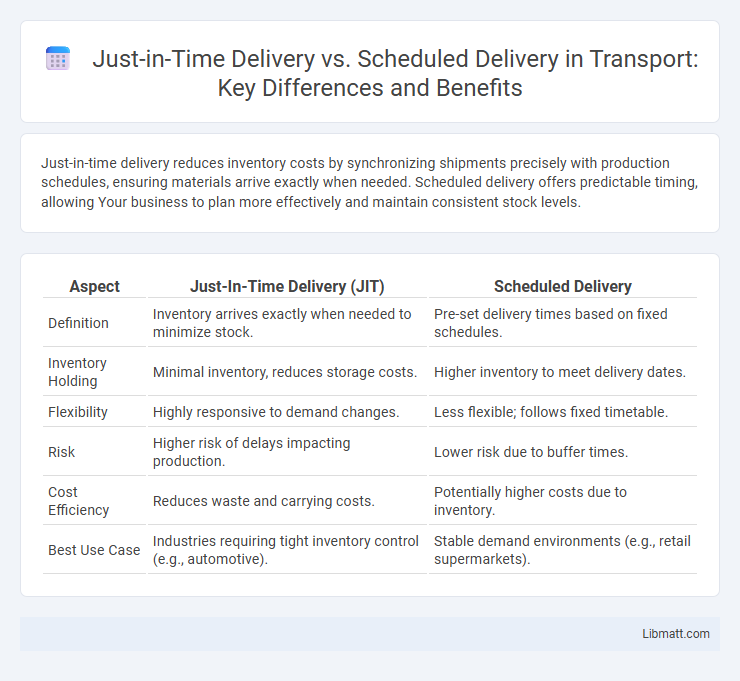

Just-in-time delivery reduces inventory costs by synchronizing shipments precisely with production schedules, ensuring materials arrive exactly when needed. Scheduled delivery offers predictable timing, allowing Your business to plan more effectively and maintain consistent stock levels.

Table of Comparison

| Aspect | Just-In-Time Delivery (JIT) | Scheduled Delivery |

|---|---|---|

| Definition | Inventory arrives exactly when needed to minimize stock. | Pre-set delivery times based on fixed schedules. |

| Inventory Holding | Minimal inventory, reduces storage costs. | Higher inventory to meet delivery dates. |

| Flexibility | Highly responsive to demand changes. | Less flexible; follows fixed timetable. |

| Risk | Higher risk of delays impacting production. | Lower risk due to buffer times. |

| Cost Efficiency | Reduces waste and carrying costs. | Potentially higher costs due to inventory. |

| Best Use Case | Industries requiring tight inventory control (e.g., automotive). | Stable demand environments (e.g., retail supermarkets). |

Introduction to Just-in-Time and Scheduled Delivery

Just-in-time (JIT) delivery minimizes inventory costs by receiving goods precisely when needed in the production process, reducing storage needs and enhancing efficiency. Scheduled delivery coordinates shipments on fixed dates regardless of immediate demand, ensuring predictability and stability in supply chains. Understanding these methods helps you choose the best approach to optimize inventory management and operational performance.

Key Concepts: What Is Just-in-Time Delivery?

Just-in-time delivery is a logistics strategy that emphasizes receiving goods exactly when they are needed in the production process, minimizing inventory costs and reducing storage space requirements. Scheduled delivery, by contrast, involves receiving shipments at predetermined intervals regardless of immediate demand, which can lead to excess inventory and higher holding expenses. Understanding your operational needs and supply chain dynamics is crucial to choosing between just-in-time and scheduled delivery for optimal efficiency.

Key Concepts: What Is Scheduled Delivery?

Scheduled delivery involves setting specific, predetermined times for shipments to arrive, enabling precise planning and resource allocation within supply chain operations. This method minimizes inventory holding costs by aligning deliveries with production schedules or customer demand forecasts. In contrast to just-in-time delivery, scheduled delivery provides predictability and stability, reducing risks of last-minute disruptions or delays.

Main Differences Between Just-in-Time and Scheduled Delivery

Just-in-time delivery minimizes inventory by coordinating shipments precisely when needed, reducing storage costs and waste. Scheduled delivery follows a fixed timetable, ensuring regular supply intervals but requiring larger storage to buffer demand fluctuations. Your choice depends on balancing inventory costs, supply chain flexibility, and demand predictability.

Advantages of Just-in-Time Delivery

Just-in-time (JIT) delivery minimizes inventory holding costs by receiving goods only as they are needed in the production process, enhancing cash flow and reducing storage space requirements. It improves operational efficiency by reducing waste and enabling faster response to market demands, leading to increased flexibility and customer satisfaction. JIT systems also streamline supply chain management, fostering closer supplier relationships and reducing the risk of overstock or obsolescence.

Advantages of Scheduled Delivery

Scheduled delivery offers predictable timing that enhances inventory management and reduces storage costs, especially for businesses with regular order cycles. It improves supply chain coordination by aligning deliveries with production schedules and demand forecasts, minimizing delays and stockouts. This reliability facilitates better resource allocation and customer satisfaction through assured availability of goods.

Challenges and Risks of Just-in-Time Delivery

Just-in-time (JIT) delivery faces significant challenges such as supply chain disruptions, which can halt production lines and increase costs due to lack of inventory buffers. Risks include dependency on precise timing from suppliers, making businesses vulnerable to delays caused by transportation issues, natural disasters, or demand fluctuations. Unlike scheduled delivery, JIT requires robust communication and real-time coordination to maintain efficiency and avoid stockouts.

Challenges and Risks of Scheduled Delivery

Scheduled delivery faces challenges such as increased inventory holding costs due to fixed arrival times, which can lead to warehouse congestion and inefficiencies. The rigidity of scheduled delivery makes it vulnerable to disruptions from supply chain delays, resulting in missed deadlines and customer dissatisfaction. Furthermore, inflexibility in adjusting delivery schedules limits responsiveness to sudden demand fluctuations, increasing the risk of stockouts or overstock situations.

Industry Applications: When to Use Each Delivery Method

Just-in-time delivery is ideal for industries like automotive manufacturing and electronics, where minimizing inventory costs and responding quickly to production demands are critical. Scheduled delivery suits sectors such as retail and food distribution, where consistent replenishment and predictable stock management improve operational efficiency. You should select the delivery method based on your industry's demand variability, inventory sensitivity, and the need for flexibility or reliability in supply chains.

Choosing the Right Delivery Approach for Your Business

Just-in-time delivery minimizes inventory costs by receiving goods exactly when needed, enhancing cash flow and reducing storage requirements, ideal for businesses with high demand variability and tight production schedules. Scheduled delivery offers consistent, predictable inventory replenishment, supporting stable supply chains and long-term planning, suitable for businesses with steady demand and bulk ordering strategies. Evaluating demand patterns, inventory capacity, and operational flexibility helps determine the optimal delivery approach to balance cost efficiency and service reliability.

just-in-time delivery vs scheduled delivery Infographic

libmatt.com

libmatt.com