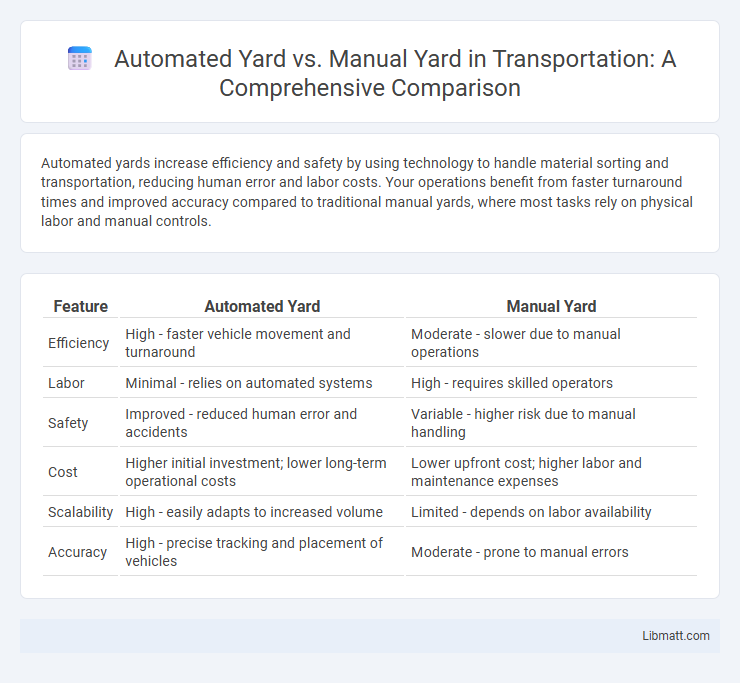

Automated yards increase efficiency and safety by using technology to handle material sorting and transportation, reducing human error and labor costs. Your operations benefit from faster turnaround times and improved accuracy compared to traditional manual yards, where most tasks rely on physical labor and manual controls.

Table of Comparison

| Feature | Automated Yard | Manual Yard |

|---|---|---|

| Efficiency | High - faster vehicle movement and turnaround | Moderate - slower due to manual operations |

| Labor | Minimal - relies on automated systems | High - requires skilled operators |

| Safety | Improved - reduced human error and accidents | Variable - higher risk due to manual handling |

| Cost | Higher initial investment; lower long-term operational costs | Lower upfront cost; higher labor and maintenance expenses |

| Scalability | High - easily adapts to increased volume | Limited - depends on labor availability |

| Accuracy | High - precise tracking and placement of vehicles | Moderate - prone to manual errors |

Introduction to Automated Yard vs Manual Yard

Automated yards use advanced technology such as robotics, sensors, and software systems to streamline container handling, improve efficiency, and reduce human error, whereas manual yards rely heavily on human labor and traditional equipment for operations. Automated yards optimize space utilization and offer faster turnaround times, contributing to lower operational costs and enhanced safety standards. Your choice between automated and manual yard systems will significantly impact productivity, operational consistency, and long-term scalability.

Key Differences Between Automated and Manual Yards

Automated yards utilize advanced technologies such as robotics, GPS tracking, and automated gate access systems to streamline container handling and improve operational efficiency, whereas manual yards rely heavily on human labor and manual equipment handling. Automated systems reduce human errors, increase throughput, and optimize space utilization by precisely coordinating movements and inventory tracking. In contrast, manual yards face challenges like slower processing times, higher labor costs, and increased risk of accidents due to reliance on human operators.

Technology Used in Automated Yards

Automated yards employ advanced technologies such as robotics, GPS tracking, and AI-driven software to streamline operations, enhance accuracy, and reduce human error. These systems integrate automated cranes, conveyor belts, and sensor networks to efficiently manage cargo handling and storage without manual intervention. You benefit from faster turnaround times, improved safety, and real-time asset tracking, distinguishing automated yards from traditional manual operations.

Labor Requirements in Manual Yards

Manual yards demand significantly higher labor requirements due to tasks like equipment handling, inventory management, and safety monitoring performed by workers. This increases operational costs and complexity, as human error and fatigue can slow processes and risk accidents. Your facility can reduce labor dependency and improve efficiency by transitioning to automated yard systems.

Efficiency and Productivity Comparison

Automated yards significantly enhance efficiency by utilizing advanced technologies such as robotic cranes and real-time tracking systems to streamline cargo handling, reducing turnaround times by up to 40% compared to manual yards. Manual yards rely heavily on human labor and manual processes, often resulting in slower operations and increased error rates that diminish overall productivity. Data from port authorities reveal that automated yards achieve higher throughput with consistent accuracy, optimizing space utilization and labor costs.

Cost Implications: Automation vs Manual Operations

Automated yards significantly reduce labor costs by minimizing the need for manual intervention and increasing operational efficiency through advanced robotics and software systems. While the initial capital expenditure for automated systems is high, long-term savings arise from lower maintenance, reduced human error, and increased throughput compared to manual yards. Manual operations tend to incur ongoing labor expenses and higher risks of operational delays, often leading to increased overall costs despite lower upfront investment.

Safety Considerations in Yard Management

Automated yard management systems enhance safety by reducing human error through precise vehicle tracking and automated control mechanisms, minimizing the risk of accidents during yard operations. Manual yards rely heavily on human intervention, increasing potential hazards such as collisions, miscommunication, and unsafe equipment handling. Incorporating automation into your yard management can significantly improve safety protocols and protect both personnel and assets.

Environmental Impact of Yard Automation

Automated yards significantly reduce carbon emissions by optimizing equipment usage and minimizing idle times compared to manual yards. Advanced sensors and AI-controlled machinery decrease fuel consumption, contributing to lower environmental footprints. Your facility can achieve greater sustainability by integrating automation technologies that prioritize energy efficiency and waste reduction.

Scalability and Future-Proofing Your Yard

Automated yards significantly enhance scalability by integrating advanced robotics and AI-driven systems capable of handling increased volumes without proportional increases in labor costs. Manual yards face limitations in expansion due to dependence on human labor, which raises operational costs and decreases efficiency as demand grows. Investing in automated technology future-proofs yard operations by enabling seamless adaptation to evolving logistics demands and innovations in supply chain management.

Choosing the Right Yard Solution for Your Business

Automated yards enhance operational efficiency by integrating real-time tracking systems and automated gate controls, reducing labor costs and minimizing human error. Manual yards, while requiring more workforce and prone to slower processing times, offer flexibility for smaller operations or those with variable demand. Selecting the right yard solution depends on factors such as business scale, budget constraints, throughput requirements, and desired level of technological integration.

Automated Yard vs Manual Yard Infographic

libmatt.com

libmatt.com