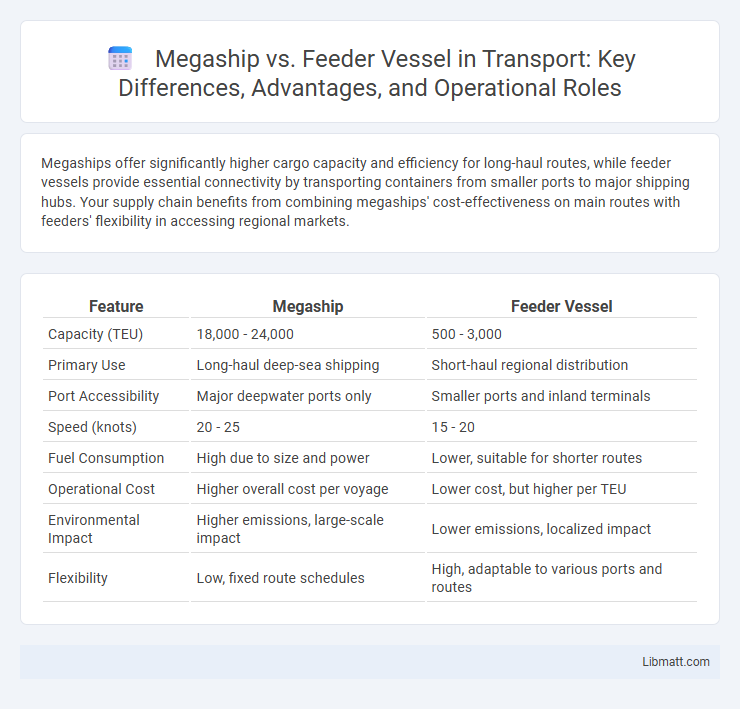

Megaships offer significantly higher cargo capacity and efficiency for long-haul routes, while feeder vessels provide essential connectivity by transporting containers from smaller ports to major shipping hubs. Your supply chain benefits from combining megaships' cost-effectiveness on main routes with feeders' flexibility in accessing regional markets.

Table of Comparison

| Feature | Megaship | Feeder Vessel |

|---|---|---|

| Capacity (TEU) | 18,000 - 24,000 | 500 - 3,000 |

| Primary Use | Long-haul deep-sea shipping | Short-haul regional distribution |

| Port Accessibility | Major deepwater ports only | Smaller ports and inland terminals |

| Speed (knots) | 20 - 25 | 15 - 20 |

| Fuel Consumption | High due to size and power | Lower, suitable for shorter routes |

| Operational Cost | Higher overall cost per voyage | Lower cost, but higher per TEU |

| Environmental Impact | Higher emissions, large-scale impact | Lower emissions, localized impact |

| Flexibility | Low, fixed route schedules | High, adaptable to various ports and routes |

Introduction to Megaships and Feeder Vessels

Megaships, often exceeding 20,000 TEUs, represent the largest class of container ships designed for long-haul, high-volume cargo transport on major trade routes. Feeder vessels, typically ranging from 300 to 3,000 TEUs, serve as smaller ships that distribute containers between regional ports and larger hub ports where megaships dock. The synergy between megaships and feeder vessels optimizes global supply chains by balancing economies of scale with regional connectivity.

Key Differences in Size and Capacity

Megaships typically exceed 20,000 TEUs (twenty-foot equivalent units) in capacity, dwarfing feeder vessels which generally handle less than 3,000 TEUs. The significant size difference allows megaships to transport massive volumes of cargo across major deep-water ports, while feeder vessels serve smaller ports with shallower drafts using shorter trips to redistribute containers. Understanding these size and capacity distinctions helps you optimize shipping strategies by selecting the appropriate vessel type for specific logistical needs.

Operational Routes and Shipping Lanes

Megaships primarily operate on major international shipping lanes connecting global trade hubs like Asia, Europe, and North America, optimizing economies of scale on deep-water routes and major ports. Feeder vessels serve secondary and regional ports with limited infrastructure, navigating shorter, less congested operational routes to facilitate cargo transfer to and from megaships. This hierarchical route system enhances port efficiency by enabling megaships to focus on long-haul voyages while feeders distribute goods to smaller, regional markets.

Cost Efficiency and Economies of Scale

Megaships deliver significant cost efficiency by transporting thousands of containers at once, reducing the per-unit shipping cost through economies of scale. Feeder vessels operate smaller loads between regional ports, offering flexibility but at a higher cost per container compared to megaships. Your shipping strategy benefits from balancing megaships for long-haul, volume-based routes with feeders for last-mile deliveries, optimizing overall logistics costs.

Flexibility and Port Accessibility

Feeder vessels offer superior flexibility and port accessibility by navigating smaller, less congested harbors and efficiently connecting regional ports, unlike megaships that require deep-water terminals with advanced infrastructure. Their ability to serve a diverse range of ports minimizes delays and optimizes routing, ensuring your cargo reaches multiple destinations without the constraints imposed by the size and handling requirements of megaships. This adaptability makes feeder vessels essential for last-mile delivery and accessing areas where megaships cannot dock.

Environmental Impact and Sustainability

Megaships significantly reduce carbon emissions per TEU by maximizing cargo capacity, resulting in lower fuel consumption compared to feeder vessels operating shorter routes with smaller loads. However, feeder vessels contribute to sustainability by enabling last-mile connectivity and reducing congestion at major ports, optimizing logistics networks for reduced overall environmental impact. Integrating both vessel types in shipping strategies enhances sustainability through balanced fuel efficiency and flexible distribution.

Role in Global Supply Chains

Megaships, with their immense cargo capacity of over 20,000 TEUs, serve as the backbone of global supply chains by transporting large volumes of goods across long-distances efficiently, reducing per-unit shipping costs. Feeder vessels operate within regional and local networks, distributing cargo from megaship hubs to smaller ports that cannot accommodate large vessels, ensuring comprehensive connectivity and timely delivery. This symbiotic relationship between megaships and feeder vessels optimizes port operations, enhances route flexibility, and maintains the flow of international trade.

Technological Advancements and Innovations

Megaships leverage advanced automation systems, larger engine capacities, and optimized hull designs to maximize fuel efficiency and cargo volume, contrasting with feeder vessels that prioritize agility and access to smaller ports through compact, versatile technologies. Innovations in megaship navigation and real-time data analytics enable precise route planning and reduced emissions, while feeder vessels integrate modular loading systems and hybrid propulsion to enhance sustainability and operational flexibility. Your supply chain benefits from these technological advancements by balancing the economies of scale offered by megaships with the localized reach and adaptability of feeder vessels.

Challenges Facing Megaships and Feeders

Megaships face challenges such as port infrastructure limitations, including insufficient berth depth and crane capacity, causing delays and increasing operational costs. Feeder vessels encounter issues with congestion in small ports and inefficient transshipment processes, impacting turnaround times and logistics coordination. Both vessel types demand advanced scheduling systems to optimize cargo flow and mitigate bottlenecks in global supply chains.

Future Trends in Maritime Transportation

Mega-ships dominate future maritime transportation by offering unparalleled economies of scale and reduced per-unit shipping costs, driving ports to upgrade infrastructure for deeper drafts and larger cranes. Feeder vessels complement this trend by enabling efficient last-mile distribution and access to smaller ports, maintaining network flexibility and resilience. Innovations in automation and digital logistics further enhance the synergy between megaships and feeders, optimizing global supply chain efficiency.

megaship vs feeder vessel Infographic

libmatt.com

libmatt.com