Part truckload (PTL) offers a balance between full truckload and less-than-truckload (LTL) shipping by transporting larger freight volumes that don't require a full trailer, reducing costs and transit times compared to LTL. Your choice depends on shipment size and urgency, with PTL providing more space and faster delivery than LTL, which is ideal for smaller, less time-sensitive loads.

Table of Comparison

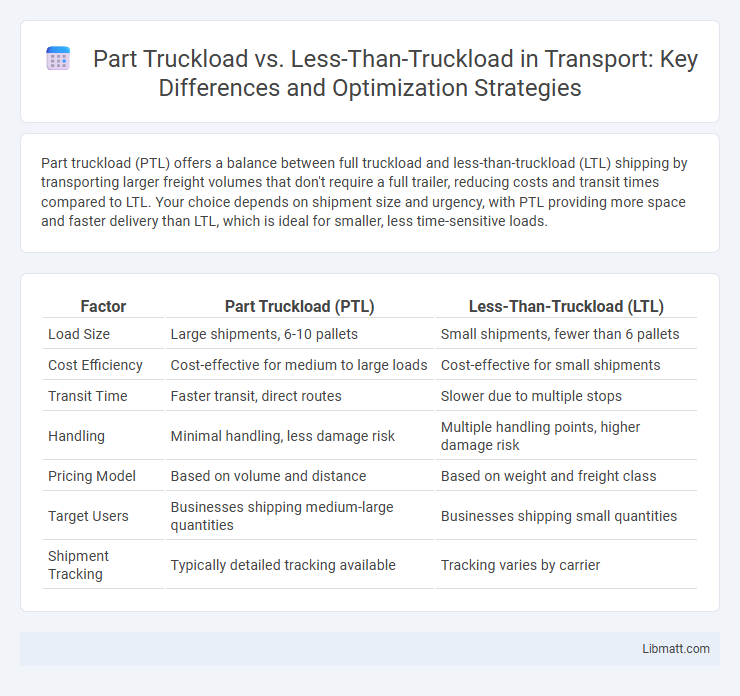

| Factor | Part Truckload (PTL) | Less-Than-Truckload (LTL) |

|---|---|---|

| Load Size | Large shipments, 6-10 pallets | Small shipments, fewer than 6 pallets |

| Cost Efficiency | Cost-effective for medium to large loads | Cost-effective for small shipments |

| Transit Time | Faster transit, direct routes | Slower due to multiple stops |

| Handling | Minimal handling, less damage risk | Multiple handling points, higher damage risk |

| Pricing Model | Based on volume and distance | Based on weight and freight class |

| Target Users | Businesses shipping medium-large quantities | Businesses shipping small quantities |

| Shipment Tracking | Typically detailed tracking available | Tracking varies by carrier |

Understanding Part Truckload and Less-Than-Truckload Shipping

Part truckload (PTL) shipping bridges the gap between full truckload and less-than-truckload (LTL) by accommodating shipments too large for LTL but not enough to fill an entire trailer. PTL offers greater cost efficiency and faster transit times than LTL due to reduced handling and direct routes, while LTL consolidates multiple smaller shipments from different customers, optimizing space and lowering costs for small loads. Both shipping methods cater to varying shipment sizes, with PTL ideal for mid-sized freight between 6 to 15 pallets and LTL suited for shipments under six pallets or 10,000 pounds.

Key Differences Between PTL and LTL Freight

Part truckload (PTL) and less-than-truckload (LTL) freight differ primarily in shipment size and handling. PTL typically involves larger shipments that don't require a full truck but are more than half a truckload, offering faster transit with minimal stops. LTL freight consolidates multiple smaller shipments from different shippers, optimizing cost efficiency but often resulting in longer transit times and more handling points.

When to Choose Part Truckload Shipping

Part truckload shipping is ideal when your shipment size exceeds less-than-truckload (LTL) limits but doesn't require a full truck, offering a cost-effective balance between space and budget. You benefit from reduced handling and faster transit compared to LTL, minimizing the risk of damage and delays. Choose part truckload when your freight demands dedicated space without the expense of a reserved full truckload.

Benefits of Less-Than-Truckload (LTL) Services

Less-Than-Truckload (LTL) shipping offers cost efficiency by allowing multiple shippers to share the same trailer space, reducing expenses for smaller freight shipments. LTL services provide enhanced flexibility with frequent pick-up and delivery options tailored for shipments typically weighing between 150 and 15,000 pounds. The access to advanced tracking technology and consolidated freight solutions improves supply chain reliability and visibility, making LTL ideal for businesses seeking optimized logistics without the expense of full truckload commitments.

Cost Comparison: PTL vs LTL

Part truckload (PTL) typically offers a cost advantage over less-than-truckload (LTL) shipping when your freight volume approaches a full truck but doesn't fill it completely. LTL rates are generally higher per unit due to multiple handling, increased pickup and delivery stops, and longer transit times. By choosing PTL, you can reduce costs by minimizing touchpoints and optimizing space utilization for shipments that are too large for LTL but not enough for full truckload pricing.

Transit Times: What to Expect

Transit times for full truckload (FTL) shipments usually range from 1 to 3 days depending on distance and route, ensuring faster delivery due to direct shipping without stops. Less-than-truckload (LTL) transit times average 3 to 7 days as shipments consolidate multiple orders, increasing handling and potential delays. Aligning your delivery expectations with these time frames optimizes supply chain planning and customer satisfaction.

Shipment Size and Capacity Considerations

Part truckload shipments typically range from 6 to 10 pallet spaces, offering more capacity than less-than-truckload (LTL), which usually handles shipments under 6 pallets or 15 linear feet. Your choice depends on shipment size, with part truckload ideal for medium-sized loads that exceed LTL limits but do not require a full truck. Optimizing shipment capacity reduces transportation costs and improves supply chain efficiency.

Common Industries Using PTL and LTL

Part truckload (PTL) and less-than-truckload (LTL) shipping serve different needs across various industries. Retail and manufacturing sectors commonly utilize LTL for frequent, smaller shipments that do not require a full trailer, optimizing cost and efficiency for inventory replenishment. In contrast, automotive and heavy machinery industries favor PTL for transporting larger, partial loads that are too big for LTL but do not fill an entire truck, balancing load capacity with cost-effectiveness.

Choosing the Right Freight Solution for Your Business

Choosing the right freight solution hinges on understanding the core differences between part truckload and less-than-truckload (LTL) shipping options. Part truckload offers a balance by reserving space for shipments that are too large for LTL but don't require a full truck, optimizing cost efficiency and transit times. Your business benefits from selecting the option that matches shipment size and delivery urgency, ensuring both budget control and supply chain reliability.

Tips for Optimizing Your Freight Shipments

Optimizing freight shipments involves choosing between part truckload (PTL) and less-than-truckload (LTL) based on shipment size and delivery timelines, as PTL suits medium-sized loads requiring faster transit while LTL is cost-effective for smaller shipments. Consolidate shipments to maximize trailer space and reduce per-unit cost, leveraging carriers that offer flexible routing and tracking technologies to improve efficiency. Regularly analyze shipping data to adjust load strategies, negotiate rates based on volume commitments, and minimize handling to prevent damage and delays.

part truckload vs less-than-truckload Infographic

libmatt.com

libmatt.com