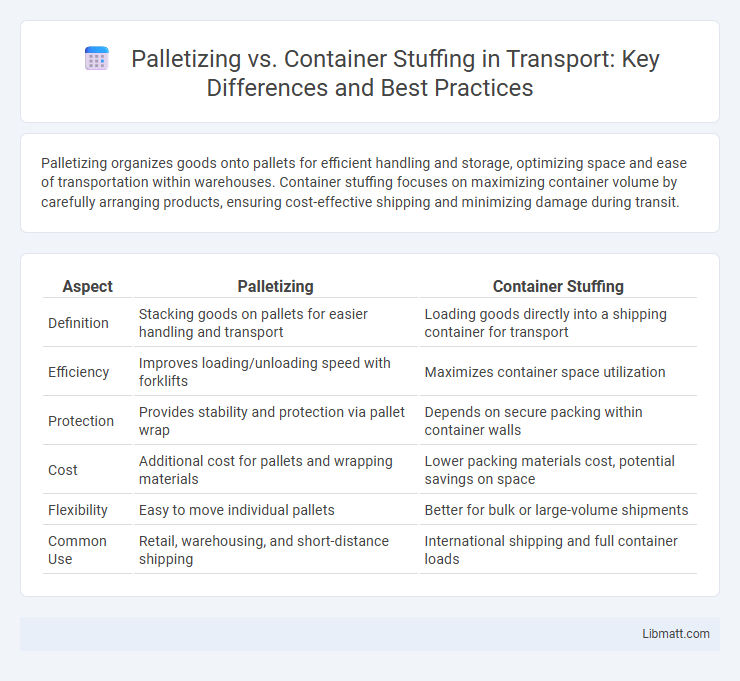

Palletizing organizes goods onto pallets for efficient handling and storage, optimizing space and ease of transportation within warehouses. Container stuffing focuses on maximizing container volume by carefully arranging products, ensuring cost-effective shipping and minimizing damage during transit.

Table of Comparison

| Aspect | Palletizing | Container Stuffing |

|---|---|---|

| Definition | Stacking goods on pallets for easier handling and transport | Loading goods directly into a shipping container for transport |

| Efficiency | Improves loading/unloading speed with forklifts | Maximizes container space utilization |

| Protection | Provides stability and protection via pallet wrap | Depends on secure packing within container walls |

| Cost | Additional cost for pallets and wrapping materials | Lower packing materials cost, potential savings on space |

| Flexibility | Easy to move individual pallets | Better for bulk or large-volume shipments |

| Common Use | Retail, warehousing, and short-distance shipping | International shipping and full container loads |

Introduction to Palletizing and Container Stuffing

Palletizing involves stacking goods on a pallet to maximize stability and ease of handling during storage and transportation, while container stuffing refers to the strategic loading of cargo inside shipping containers to optimize space utilization and prevent damage. Efficient palletizing improves warehouse organization and forklift operation efficiency, whereas proper container stuffing ensures secure shipment and cost-effective use of container volume. Both processes require meticulous planning and coordination to enhance supply chain logistics and reduce operational costs.

Key Differences Between Palletizing and Container Stuffing

Palletizing involves stacking goods on pallets for easy handling and transport, enhancing stability and protection during shipping, while container stuffing refers to loading items directly into a shipping container with optimized space utilization. The key difference lies in palletizing's focus on mechanical efficiency and product protection versus container stuffing's emphasis on maximizing container capacity and load distribution. Palletizing is ideal for standardized loads, whereas container stuffing suits irregular or bulk cargo requiring customized arrangements within the container.

Advantages of Palletizing

Palletizing offers significant advantages such as improved stability and easier handling during transportation and storage, reducing damage to goods. It streamlines loading and unloading processes by allowing forklifts and pallet jacks to move multiple items at once, increasing efficiency. Your supply chain benefits from optimized space utilization and faster inventory management, leading to cost savings and better overall organization.

Benefits of Container Stuffing

Container stuffing maximizes space utilization by efficiently arranging goods, reducing transportation costs and minimizing the risk of damage during transit. It enables better inventory management through precise load planning and improves security by limiting cargo movement within the container. Optimized container stuffing contributes to faster unloading processes and enhances overall supply chain efficiency.

Cost Comparison: Palletizing vs Container Stuffing

Palletizing often incurs higher upfront costs due to materials such as pallets, stretch wrap, and labor for stacking; however, it enhances load stability and reduces product damage, potentially lowering long-term expenses. Container stuffing can reduce immediate shipping costs by maximizing container space and minimizing packaging materials, but it may increase the risk of product damage and handling inefficiencies. Evaluating cost-effectiveness depends on factors like shipment volume, product fragility, and handling practices in supply chain logistics.

Efficiency and Speed in Logistics

Palletizing streamlines logistics by organizing goods into standardized, stackable units that facilitate faster handling, loading, and unloading, thereby improving overall operational efficiency. Container stuffing, while maximizing container space, often requires meticulous planning and slower manual arrangement to prevent cargo damage, impacting speed. Your choice between these methods should balance the need for rapid turnover with space optimization to enhance supply chain performance.

Impact on Product Safety and Damage

Palletizing enhances product safety by providing stable stacking and cushioning, reducing the risk of damage during handling and transportation. Container stuffing, if poorly executed, can lead to uneven weight distribution and shifting, increasing the likelihood of product damage. Your choice between palletizing and container stuffing should consider the specific fragility and packaging requirements of your products to minimize losses.

Space Utilization and Load Optimization

Palletizing enhances space utilization by organizing goods on standardized pallets, enabling efficient stacking and easier handling during transport, which maximizes container load stability and volume usage. Container stuffing requires careful arrangement of diverse cargo to optimize every cubic inch, reducing empty space and ensuring the integrity of fragile items through strategic load distribution. Both methods improve load optimization by minimizing voids, but palletizing simplifies handling logistics while container stuffing demands precise spatial planning for optimal container capacity.

Environmental Considerations

Palletizing reduces environmental impact by maximizing space efficiency and minimizing packaging waste, leading to lower fuel consumption during transportation. Container stuffing optimizes load distribution and prevents product damage, which helps reduce waste from damaged goods and returns. Your choice between palletizing and container stuffing can significantly influence the sustainability of your supply chain operations.

Choosing the Right Method for Your Supply Chain

Selecting between palletizing and container stuffing depends on your supply chain's efficiency, product protection, and space utilization needs. Palletizing offers streamlined handling and minimizes damage through standardized stacking, ideal for bulk shipments and consistent loads. Container stuffing maximizes container volume by arranging diverse or irregular products precisely, enhancing cost-effectiveness in international freight.

palletizing vs container stuffing Infographic

libmatt.com

libmatt.com