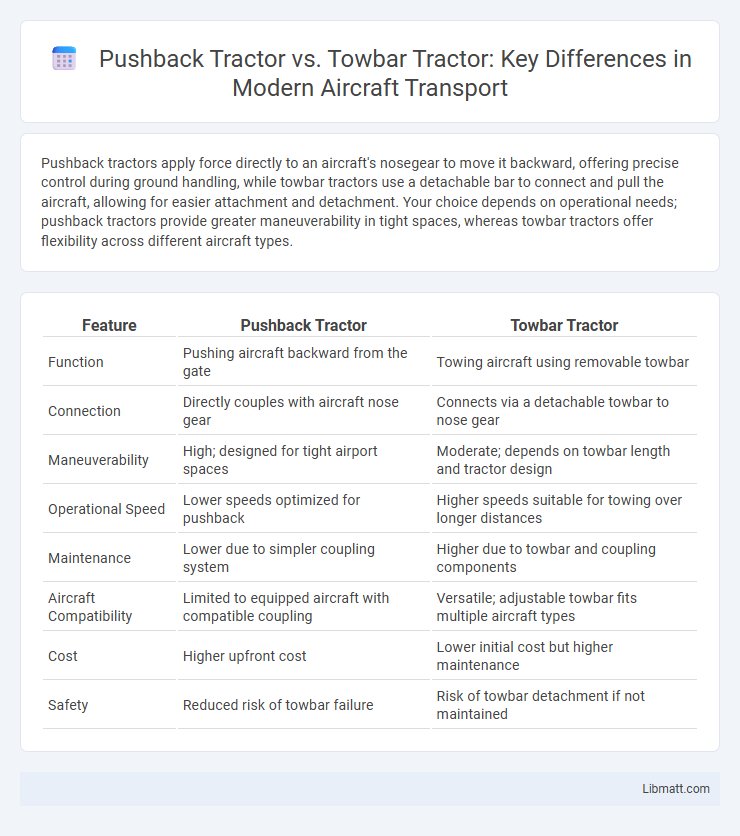

Pushback tractors apply force directly to an aircraft's nosegear to move it backward, offering precise control during ground handling, while towbar tractors use a detachable bar to connect and pull the aircraft, allowing for easier attachment and detachment. Your choice depends on operational needs; pushback tractors provide greater maneuverability in tight spaces, whereas towbar tractors offer flexibility across different aircraft types.

Table of Comparison

| Feature | Pushback Tractor | Towbar Tractor |

|---|---|---|

| Function | Pushing aircraft backward from the gate | Towing aircraft using removable towbar |

| Connection | Directly couples with aircraft nose gear | Connects via a detachable towbar to nose gear |

| Maneuverability | High; designed for tight airport spaces | Moderate; depends on towbar length and tractor design |

| Operational Speed | Lower speeds optimized for pushback | Higher speeds suitable for towing over longer distances |

| Maintenance | Lower due to simpler coupling system | Higher due to towbar and coupling components |

| Aircraft Compatibility | Limited to equipped aircraft with compatible coupling | Versatile; adjustable towbar fits multiple aircraft types |

| Cost | Higher upfront cost | Lower initial cost but higher maintenance |

| Safety | Reduced risk of towbar failure | Risk of towbar detachment if not maintained |

Introduction to Aircraft Towing Methods

Pushback tractors are specialized vehicles designed to safely maneuver aircraft away from the gate, using direct contact with the aircraft's nose gear, ensuring precise control during ground operations. Towbar tractors rely on a towbar connected between the tractor and the aircraft, enabling movement while keeping the aircraft's steering systems engaged, which is essential for longer-distance towing and repositioning. Understanding these towing methods is crucial for optimizing your ground handling procedures and enhancing airport operational efficiency.

What is a Pushback Tractor?

A pushback tractor is a specialized aircraft ground support vehicle designed to move airplanes backward from the gate area, using a tow bar or a towbarless system to connect directly to the aircraft's nose landing gear. Unlike towbar tractors that require a detachable tow bar for connecting to the aircraft, pushback tractors can apply precise controlled force to safely maneuver aircraft in tight spaces on the ramp. Your ground operations benefit from enhanced efficiency and safety with pushback tractors due to their powerful engines and advanced steering capabilities tailored specifically for aircraft movement.

What is a Towbar Tractor?

A towbar tractor is a specialized aircraft ground support vehicle designed to move airplanes by connecting to the aircraft's towbar, providing precise control during pushback and towing operations. Unlike pushback tractors, which directly engage the aircraft's nose gear, towbar tractors rely on the removable towbar to create a flexible connection, allowing for safer maneuvering around airport ramps. Your ground handling efficiency can improve with a towbar tractor, especially when handling various aircraft types requiring adaptable towing solutions.

Key Differences Between Pushback and Towbar Tractors

Pushback tractors are designed to connect directly to an aircraft's nose gear, allowing precise control and maneuverability during aircraft pushback operations, whereas towbar tractors use a towbar to link the tractor to the aircraft, accommodating various aircraft types with versatile coupling options. Pushback tractors provide increased efficiency and safety by reducing the number of connections and potential failure points compared to towbar tractors, which rely on removable towbars prone to wear or mishandling. The choice between pushback and towbar tractors depends on airport operational needs, aircraft compatibility, and the emphasis on minimizing turnaround times.

Advantages of Pushback Tractors

Pushback tractors offer enhanced maneuverability and reduced risk of damage to aircraft compared to towbar tractors, as they connect directly to the aircraft's nose gear without requiring a towbar. These tractors provide greater operational efficiency by enabling smoother, more precise movements during pushback and towing operations on the ramp. Their compact design and direct coupling system contribute to faster turnaround times and improved safety in busy airport environments.

Benefits of Towbar Tractors

Towbar tractors offer increased maneuverability and flexibility by allowing aircraft to pivot naturally during pushback, reducing strain on landing gear and minimizing damage risk. Their design supports quick attachment and detachment, improving operational efficiency and reducing turnaround time. You benefit from enhanced safety and cost-effectiveness in ground handling operations with towbar tractors.

Operational Safety Considerations

Pushback tractors enhance operational safety by providing greater control and stability during aircraft movement, reducing the risk of damage to the aircraft and ground personnel. Towbar tractors depend on the towbar's integrity and proper attachment, increasing the potential for accidents if connections fail or are mishandled. Your choice impacts safety protocols, as pushback tractors eliminate hazards linked to towbar failures, ensuring safer ground operations.

Cost and Maintenance Comparison

Pushback tractors generally have higher upfront costs due to their robust design and integrated features but require less frequent maintenance because of their durable construction and simpler mechanical systems. Towbar tractors typically incur lower initial purchase prices but demand more frequent maintenance on the towbar assembly and added strain on aircraft landing gear, potentially increasing long-term expenses. Operators seeking cost efficiency must balance pushback tractors' higher capital investment against towbar tractors' ongoing maintenance and equipment wear costs.

Applications and Use Cases in Airports

Pushback tractors are primarily used for maneuvering aircraft from the gate to the taxiway, ideal for short-distance, precise positioning in congested airport aprons. Towbar tractors excel in towing aircraft over longer distances, such as moving planes between hangars or maintenance areas, due to their enhanced pulling power and versatility across various towbar-compatible aircraft. Your choice depends on operational needs, with pushback tractors offering agility for gate operations and towbar tractors providing robust performance for diverse towing tasks.

Choosing the Right Tractor for Your Fleet

Selecting the right tractor for your fleet depends on operational needs and aircraft compatibility, with pushback tractors offering powerful, direct nose gear engagement for larger planes, while towbar tractors provide versatility across various aircraft types through an adaptable towbar system. Pushback tractors deliver enhanced control and reduced stress on aircraft landing gear, making them ideal for consistent use with specific large aircraft models, whereas towbar tractors offer economic benefits and flexibility in mixed-fleet environments. Evaluate your fleet's size, types, and ground handling requirements to ensure your investment optimizes efficiency and safety in aircraft movement operations.

pushback tractor vs towbar tractor Infographic

libmatt.com

libmatt.com