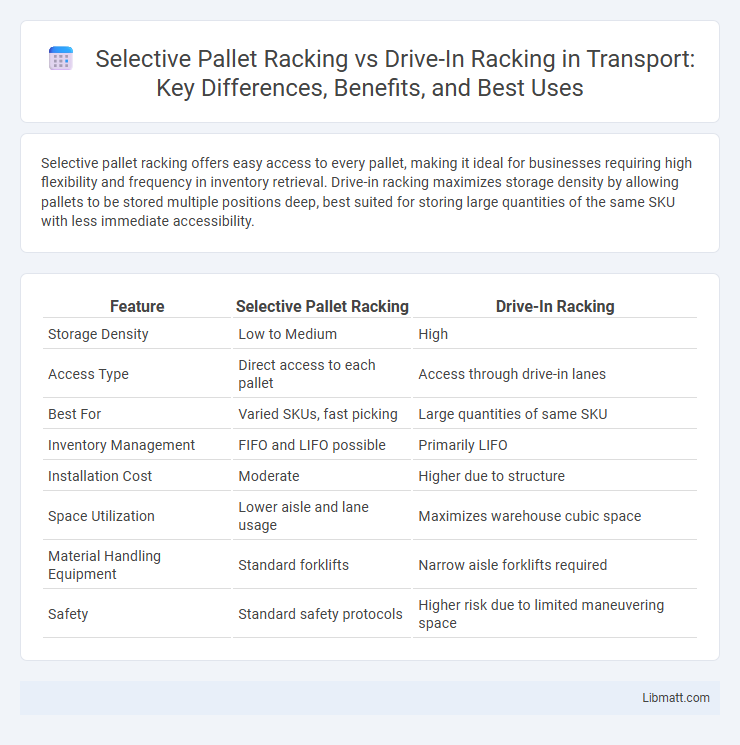

Selective pallet racking offers easy access to every pallet, making it ideal for businesses requiring high flexibility and frequency in inventory retrieval. Drive-in racking maximizes storage density by allowing pallets to be stored multiple positions deep, best suited for storing large quantities of the same SKU with less immediate accessibility.

Table of Comparison

| Feature | Selective Pallet Racking | Drive-In Racking |

|---|---|---|

| Storage Density | Low to Medium | High |

| Access Type | Direct access to each pallet | Access through drive-in lanes |

| Best For | Varied SKUs, fast picking | Large quantities of same SKU |

| Inventory Management | FIFO and LIFO possible | Primarily LIFO |

| Installation Cost | Moderate | Higher due to structure |

| Space Utilization | Lower aisle and lane usage | Maximizes warehouse cubic space |

| Material Handling Equipment | Standard forklifts | Narrow aisle forklifts required |

| Safety | Standard safety protocols | Higher risk due to limited maneuvering space |

Overview of Selective Pallet Racking

Selective pallet racking offers direct aisle access to each pallet, making it ideal for warehouses with diverse inventory and frequent product turnover. This system maximizes storage flexibility and improves inventory management by allowing you to easily pick and replenish items without moving other pallets. Compared to drive-in racking, selective pallet racking provides better accessibility and faster retrieval times, enhancing overall warehouse efficiency.

Overview of Drive-In Racking

Drive-In Racking maximizes warehouse storage density by allowing forklifts to drive directly into the rack structure to store and retrieve pallets. This system is ideal for high-volume, low-SKU operations where inventory turnover is slow, offering deep lane storage with minimal aisle space. You can optimize space utilization but may sacrifice selectivity compared to Selective Pallet Racking, which provides easier access to each pallet.

Key Differences Between Selective and Drive-In Racking

Selective pallet racking offers direct access to every pallet, making it ideal for diverse inventory with frequent rotation, while drive-in racking maximizes storage density by allowing forklifts to enter storage lanes, suited for high-volume, low-SKU environments. Selective racking supports a wide range of SKU management with easy pick-and-place operations, whereas drive-in racking follows a Last-In, First-Out (LIFO) system, optimizing space but limiting pallet accessibility. The structural design of selective racks focuses on versatility and accessibility, whereas drive-in racks emphasize deep storage and compact footprint for warehouses prioritizing space efficiency.

Storage Density Comparison

Selective pallet racking offers lower storage density as it provides direct access to each pallet, resulting in more aisle space and less overall storage capacity. Drive-in racking maximizes storage density by allowing pallets to be stored multiple rows deep without aisles between them, ideal for high-volume, homogeneous inventory. Your choice should consider the trade-off between accessibility and space efficiency based on inventory turnover and storage needs.

Accessibility and Selectivity

Selective pallet racking offers maximum accessibility and selectivity, allowing you to retrieve any pallet directly without moving others, ideal for warehouses requiring frequent inventory rotation. Drive-in racking maximizes storage density by stacking pallets deep within the system but limits selectivity, as access is usually restricted to first-in, last-out (FILO) pallets. Choosing between these systems depends on your need for individual pallet access versus high storage capacity.

Space Utilization

Selective pallet racking offers high accessibility by allowing individual pallet retrieval, but it sacrifices some space utilization due to aisles between racks. Drive-in racking maximizes storage density by eliminating multiple aisles, enabling pallets to be stored several deep on rails within a single bay. This system is ideal for storing large quantities of homogeneous products, providing superior space utilization in warehouses with limited aisle width.

Cost Implications and Budget Considerations

Selective pallet racking offers lower initial costs and greater flexibility, making it a cost-effective choice for diverse inventory and smaller budgets. Drive-in racking requires higher upfront investment due to its structural complexity but maximizes storage density, potentially reducing warehouse footprint and long-term space costs. Careful evaluation of inventory turnover rates and available warehouse space is crucial to balance budget constraints with storage efficiency between these systems.

Inventory Management and Rotation Methods

Selective pallet racking offers superior inventory management by providing direct access to each pallet, facilitating efficient FIFO (First-In, First-Out) rotation and accurate stock control. Drive-in racking maximizes storage density but uses LIFO (Last-In, First-Out) rotation, which can complicate inventory tracking and reduce flexibility in managing your stock. For optimized inventory turnover and precise rotation, selective pallet racking is generally preferred in environments requiring frequent access to individual pallets.

Ideal Applications for Each Racking Type

Selective pallet racking is ideal for warehouses requiring high accessibility and frequent stock rotation, such as retail or distribution centers handling diverse product lines. Drive-in racking suits facilities with limited space that store large quantities of homogeneous products, like cold storage or bulk inventory warehouses, where maximizing storage density is crucial. Understanding your inventory turnover and space constraints will help determine which racking system optimizes storage efficiency and operational workflow.

Choosing the Right Racking System for Your Warehouse

Selecting the right racking system depends on your warehouse's storage needs and inventory characteristics. Selective pallet racking offers easy access to each pallet, ideal for high SKU variety and frequent picking, while drive-in racking maximizes space by allowing deep pallet storage but limits individual pallet accessibility. Understanding your inventory turnover and space optimization goals helps you determine whether selective or drive-in racking best supports your operational efficiency.

selective pallet racking vs drive-in racking Infographic

libmatt.com

libmatt.com