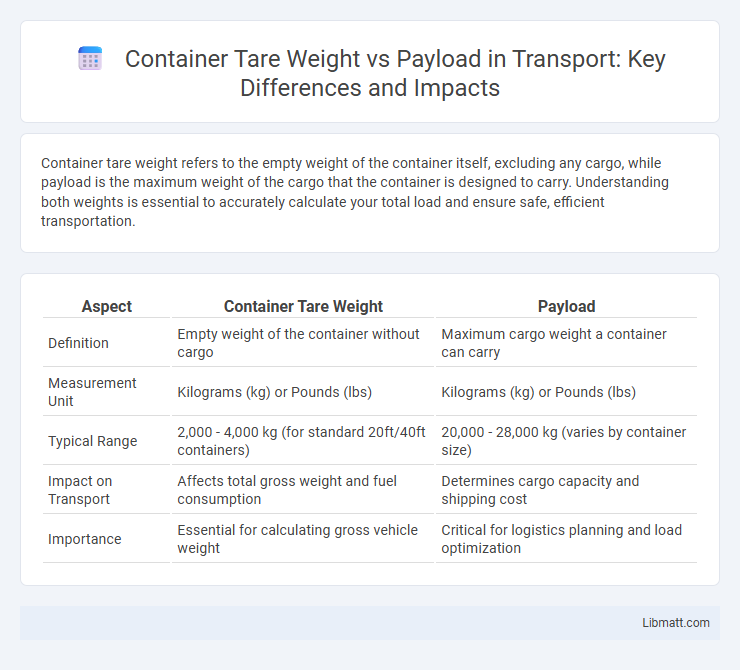

Container tare weight refers to the empty weight of the container itself, excluding any cargo, while payload is the maximum weight of the cargo that the container is designed to carry. Understanding both weights is essential to accurately calculate your total load and ensure safe, efficient transportation.

Table of Comparison

| Aspect | Container Tare Weight | Payload |

|---|---|---|

| Definition | Empty weight of the container without cargo | Maximum cargo weight a container can carry |

| Measurement Unit | Kilograms (kg) or Pounds (lbs) | Kilograms (kg) or Pounds (lbs) |

| Typical Range | 2,000 - 4,000 kg (for standard 20ft/40ft containers) | 20,000 - 28,000 kg (varies by container size) |

| Impact on Transport | Affects total gross weight and fuel consumption | Determines cargo capacity and shipping cost |

| Importance | Essential for calculating gross vehicle weight | Critical for logistics planning and load optimization |

Understanding Container Tare Weight

Container tare weight represents the empty weight of the container itself, excluding any cargo or payload inside. This weight is crucial for accurately calculating the total weight your container will carry, ensuring compliance with transportation safety regulations. Understanding the tare weight helps optimize payload capacity without exceeding legal weight limits.

What Is Container Payload?

Container payload refers to the maximum weight of cargo that a shipping container can safely carry, excluding the container's own tare weight. Understanding the payload is crucial for optimizing your freight capacity and ensuring compliance with shipping regulations. Accurate calculation of container payload helps prevent overloading, reducing risks during transport and improving operational efficiency.

Key Differences: Tare Weight vs Payload

Tare weight refers to the empty weight of a container without any cargo, while payload represents the maximum weight of the cargo that the container can carry. Understanding the distinction between tare weight and payload is crucial for accurate load calculations, ensuring compliance with transportation regulations, and optimizing shipping efficiency. Containers have specific tare weights that vary by type and material, directly impacting the allowable payload to avoid exceeding gross weight limits.

Why Tare Weight Matters in Shipping

Tare weight is the empty weight of a shipping container, crucial for accurately calculating the maximum payload capacity and ensuring compliance with safety regulations. Knowing the tare weight helps prevent overloading, which can lead to fines, accidents, and damage to cargo or transport equipment. Your ability to optimize cargo loads while maintaining safe transport standards depends on understanding and accounting for the tare weight in shipping logistics.

Calculating Net Payload Capacity

Calculating net payload capacity requires subtracting the container tare weight from the container's gross weight limit, ensuring compliance with transportation regulations. Tare weight is the empty container's weight, crucial for accurately determining how much cargo can be safely loaded without exceeding the maximum gross weight. Understanding this distinction optimizes logistics planning by maximizing payload efficiency while preventing overloading and potential damage during transit.

Factors Affecting Tare Weight

Container tare weight is influenced by materials used, such as steel or aluminum, which impact the structural strength and weight. Design features like thickness, reinforcements, and attached equipment also contribute to variations in tare weight. External factors including corrosion, repairs, and accumulated residues can further alter the tare weight over time.

Impact on Freight Costs

Container tare weight directly affects your payload capacity by reducing the maximum allowable weight for goods, influencing freight cost calculations. Heavier tare weights mean less cargo can be loaded, potentially increasing the number of shipments and overall transportation expenses. Understanding the balance between tare weight and payload helps optimize load efficiency and minimize freight charges.

Compliance with Shipping Regulations

Compliance with shipping regulations mandates accurate calculation of container tare weight to ensure payload does not exceed legal limits, preventing fines and safety hazards. Shipping lines and regulatory bodies require precise tare weight documentation for proper weight distribution and load verification. Adhering to these standards guarantees secure vessel stability and compliance with international maritime laws such as SOLAS and the Verified Gross Mass (VGM) rules.

Common Container Sizes and Typical Weights

Common container sizes include 20-foot and 40-foot units, with standard tare weights of approximately 2,200 kg for a 20-foot container and 3,800 kg for a 40-foot container. Payload capacity varies, typically around 28,000 kg for a 20-foot container and up to 26,500 kg for a 40-foot container, reflecting the maximum load these containers can safely carry. Understanding these weights is crucial for optimizing Your shipping logistics and ensuring compliance with weight regulations.

Tips for Maximizing Container Payload

Maximizing container payload begins with understanding the tare weight, which is the container's empty weight, to accurately calculate the allowable cargo weight without exceeding limits. Selecting lightweight containers or those made from advanced materials reduces tare weight, increasing net payload capacity. Efficient cargo packing and weight distribution further optimize payload while ensuring compliance with transportation safety standards.

container tare weight vs payload Infographic

libmatt.com

libmatt.com