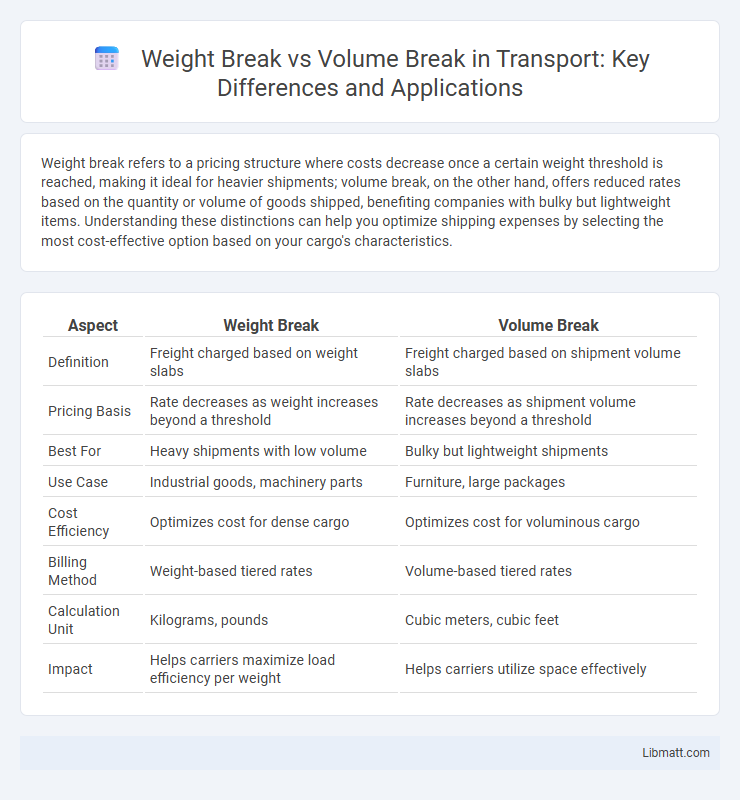

Weight break refers to a pricing structure where costs decrease once a certain weight threshold is reached, making it ideal for heavier shipments; volume break, on the other hand, offers reduced rates based on the quantity or volume of goods shipped, benefiting companies with bulky but lightweight items. Understanding these distinctions can help you optimize shipping expenses by selecting the most cost-effective option based on your cargo's characteristics.

Table of Comparison

| Aspect | Weight Break | Volume Break |

|---|---|---|

| Definition | Freight charged based on weight slabs | Freight charged based on shipment volume slabs |

| Pricing Basis | Rate decreases as weight increases beyond a threshold | Rate decreases as shipment volume increases beyond a threshold |

| Best For | Heavy shipments with low volume | Bulky but lightweight shipments |

| Use Case | Industrial goods, machinery parts | Furniture, large packages |

| Cost Efficiency | Optimizes cost for dense cargo | Optimizes cost for voluminous cargo |

| Billing Method | Weight-based tiered rates | Volume-based tiered rates |

| Calculation Unit | Kilograms, pounds | Cubic meters, cubic feet |

| Impact | Helps carriers maximize load efficiency per weight | Helps carriers utilize space effectively |

Understanding Weight Breaks and Volume Breaks

Weight breaks and volume breaks are pricing strategies used in shipping and logistics to optimize costs based on shipment characteristics. Weight breaks apply when the cost per unit decreases after reaching a certain weight threshold, benefiting You by lowering expenses for heavier shipments. Volume breaks reduce rates as the shipment size or volume increases, making it cost-effective for bulk or larger consignments.

Key Differences Between Weight and Volume Breaks

Weight break measures the minimum weight quantity required to qualify for discounted shipping rates, while volume break refers to the minimum cubic space needed for similar pricing benefits. Your shipping costs often decrease when the shipment meets or exceeds these thresholds, but weight breaks are based on mass, and volume breaks depend on the physical size of the package. Understanding these distinctions helps optimize logistics and select cost-effective shipping solutions tailored to your shipment's characteristics.

Importance of Weight Breaks in Freight Shipping

Weight breaks in freight shipping play a critical role in cost savings by allowing shippers to qualify for lower rates once their shipment exceeds a specific weight threshold. These breaks can significantly reduce your overall shipping expenses compared to paying based on volume alone, especially when heavier shipments benefit from economies of scale. Understanding weight breaks helps optimize freight charges and ensures you leverage discounts that directly impact your bottom line.

Role of Volume Breaks in Logistics Pricing

Volume breaks in logistics pricing offer discounted rates based on the total shipment volume, incentivizing businesses to consolidate shipments for cost efficiency. These breaks help carriers maximize container or truck space utilization, reducing per-unit shipping costs and enhancing overall supply chain performance. Implementing volume-based pricing strategies supports logistics providers in managing capacity while encouraging higher shipment volumes from customers.

Factors Influencing Weight vs. Volume Break Determination

Determining weight break vs. volume break involves analyzing shipment density, packaging dimensions, and transportation cost structures. Factors such as cargo type, carrier pricing models, and shipment frequency significantly impact whether weight or volume will drive cost efficiency. Understanding these variables helps you optimize logistical expenses and select the most cost-effective shipping method.

How Carriers Calculate Weight and Volume Breaks

Carriers calculate weight breaks by measuring the actual or dimensional weight of a shipment, charging rates based on predefined weight thresholds to optimize transportation costs. Volume breaks are determined by the cubic volume of goods, allowing carriers to apply discounted rates once shipment volume surpasses specific cubic feet or meter limits. Both methods ensure efficient pricing models, balancing cargo density and physical space usage in logistics management.

Impact on Shipping Costs: Weight Break vs. Volume Break

Weight break affects shipping costs by determining price thresholds based on the shipment's weight, often leading to lower rates when your cargo reaches specific weight increments. Volume break influences costs through dimensional thresholds, meaning larger parcels might qualify for discounted pricing if they fit within preset volume categories. Understanding the balance between weight break and volume break helps optimize your shipping expenses by aligning package size and weight with carrier pricing structures.

Industry-Specific Application of Breaks

Weight break pricing is commonly utilized in heavy industries such as manufacturing and construction, where bulk shipments are measured primarily by weight, allowing significant cost savings on large, heavy consignments. Volume break pricing is prevalent in retail and e-commerce sectors, where dimensional space and package size determine shipping costs, optimizing expenses for goods that are lightweight but occupy considerable volume. Both pricing strategies tailor cost structures to industry logistics, improving efficiency and aligning transportation expenses with shipment characteristics.

Common Challenges with Weight and Volume Breaks

Weight break and volume break pricing structures often present challenges such as underestimating shipping costs due to fluctuating package weights and volumes. Inaccurate forecasting can lead to unexpected expenses when shipments exceed the predefined weight or volume thresholds. You must carefully analyze your shipment patterns to optimize cost savings and avoid hidden fees associated with incorrect break points.

Best Practices for Optimizing Shipping with Breaks

Optimizing shipping with weight breaks and volume breaks requires analyzing shipment patterns to identify thresholds where cost savings occur. Weight breaks focus on cost reductions achieved when shipments exceed specific weight limits, while volume breaks leverage discounts based on the cubic size or shipment quantity. You can maximize savings by consolidating shipments to meet these breaks, negotiating tiered pricing with carriers, and leveraging freight management software to monitor and adjust shipment sizes for optimal cost efficiency.

weight break vs volume break Infographic

libmatt.com

libmatt.com