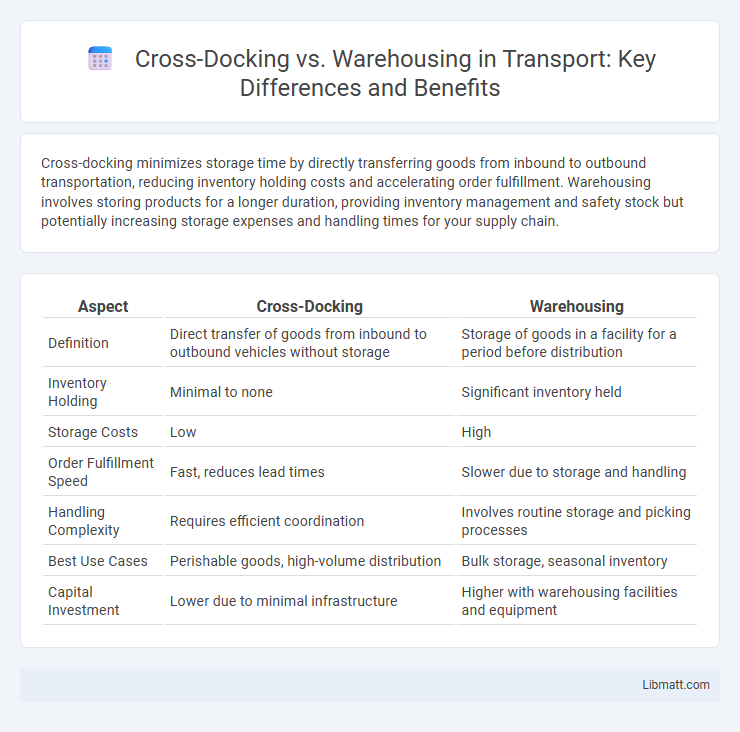

Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation, reducing inventory holding costs and accelerating order fulfillment. Warehousing involves storing products for a longer duration, providing inventory management and safety stock but potentially increasing storage expenses and handling times for your supply chain.

Table of Comparison

| Aspect | Cross-Docking | Warehousing |

|---|---|---|

| Definition | Direct transfer of goods from inbound to outbound vehicles without storage | Storage of goods in a facility for a period before distribution |

| Inventory Holding | Minimal to none | Significant inventory held |

| Storage Costs | Low | High |

| Order Fulfillment Speed | Fast, reduces lead times | Slower due to storage and handling |

| Handling Complexity | Requires efficient coordination | Involves routine storage and picking processes |

| Best Use Cases | Perishable goods, high-volume distribution | Bulk storage, seasonal inventory |

| Capital Investment | Lower due to minimal infrastructure | Higher with warehousing facilities and equipment |

Introduction to Cross-Docking and Warehousing

Cross-docking is a logistics strategy where inbound goods are directly transferred to outbound transportation with minimal or no storage time, enhancing supply chain efficiency and reducing inventory holding costs. Warehousing involves storing goods for extended periods, facilitating inventory management, order fulfillment, and buffering supply and demand fluctuations. Comparing cross-docking and warehousing highlights trade-offs between speed, inventory levels, and operational complexity in logistics management.

Core Differences Between Cross-Docking and Warehousing

Cross-docking involves the direct transfer of goods from inbound to outbound transportation with minimal or no storage time, significantly reducing inventory holding costs. Warehousing, conversely, focuses on storing products for extended periods, facilitating inventory management, order fulfillment, and buffer stock maintenance. Your choice between these logistics methods depends on factors like inventory turnover rates, storage needs, and delivery speed requirements.

How Cross-Docking Works

Cross-docking streamlines the supply chain by directly transferring products from inbound to outbound transportation with minimal storage, reducing handling time and inventory costs. This method requires efficient coordination between suppliers, warehouse staff, and transportation to ensure timely movement of goods through the dock. Your operations can benefit from faster delivery cycles and reduced storage needs by implementing cross-docking as an alternative to traditional warehousing.

How Traditional Warehousing Functions

Traditional warehousing functions by storing inventory for extended periods, allowing businesses to manage stock levels and fulfill orders as needed. It involves receiving, storing, and organizing goods in a controlled environment to ensure product availability and quality. Your supply chain benefits from increased inventory control but faces higher storage costs and longer lead times compared to cross-docking.

Advantages of Cross-Docking

Cross-docking minimizes inventory holding costs by directly transferring goods from inbound to outbound transportation, significantly reducing storage time. This process enhances supply chain efficiency, leading to faster order fulfillment and improved customer satisfaction. Real-time inventory visibility and streamlined logistics operations further optimize cross-docking advantages over traditional warehousing.

Benefits of Traditional Warehousing

Traditional warehousing offers significant benefits including storage flexibility, allowing businesses to stockpile inventory and meet varying demand without interruption. It provides crucial safety and quality control, ensuring goods are protected from damage or spoilage during extended holding periods. Warehousing also supports bulk purchasing advantages and efficient order fulfillment by consolidating products in one location for streamlined distribution.

Key Challenges in Cross-Docking vs Warehousing

Cross-docking faces key challenges like precise timing coordination, real-time inventory tracking, and reliance on a seamless supply chain to minimize storage time. Warehousing struggles with high storage costs, space optimization, and managing inventory accuracy over extended periods. Understanding these differences helps you choose the best strategy for efficient inventory management and cost control.

Cost Comparison: Cross-Docking vs Warehousing

Cross-docking significantly reduces storage costs by minimizing or eliminating inventory holding, leading to lower capital expenditures compared to traditional warehousing which requires extensive space and labor for inventory management. Operational expenses are often lower in cross-docking due to streamlined handling and faster turnover, whereas warehousing incurs ongoing costs related to utilities, security, and maintenance. Despite higher initial setup costs for cross-docking facilities, overall cost efficiency improves through reduced inventory carrying costs and expedited order fulfillment.

Best Use Cases for Each Method

Cross-docking is best suited for perishable goods, high-velocity products, and just-in-time inventory systems where minimizing storage time reduces costs and enhances flow efficiency. Warehousing excels in scenarios requiring bulk storage, order consolidation, and buffer inventory management, supporting seasonal demand fluctuations and longer supply chains. Your choice depends on whether your priority is speed and reduced handling (cross-docking) or storage flexibility and inventory control (warehousing).

Choosing the Right Solution for Your Supply Chain

Cross-docking reduces storage costs and accelerates order fulfillment by directly transferring products from inbound to outbound transportation, making it ideal for perishable goods or high-turnover inventory. Warehousing offers greater flexibility for storing diverse products and managing inventory levels, suitable for businesses with fluctuating demand or longer lead times. Evaluating your supply chain's specific needs, product characteristics, and delivery timelines helps determine whether cross-docking or warehousing will optimize efficiency and customer satisfaction.

cross-docking vs warehousing Infographic

libmatt.com

libmatt.com