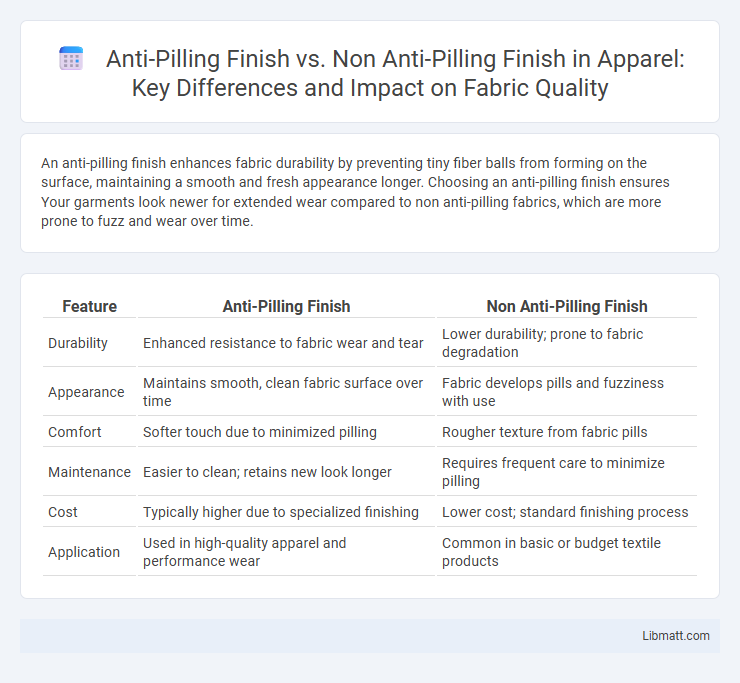

An anti-pilling finish enhances fabric durability by preventing tiny fiber balls from forming on the surface, maintaining a smooth and fresh appearance longer. Choosing an anti-pilling finish ensures Your garments look newer for extended wear compared to non anti-pilling fabrics, which are more prone to fuzz and wear over time.

Table of Comparison

| Feature | Anti-Pilling Finish | Non Anti-Pilling Finish |

|---|---|---|

| Durability | Enhanced resistance to fabric wear and tear | Lower durability; prone to fabric degradation |

| Appearance | Maintains smooth, clean fabric surface over time | Fabric develops pills and fuzziness with use |

| Comfort | Softer touch due to minimized pilling | Rougher texture from fabric pills |

| Maintenance | Easier to clean; retains new look longer | Requires frequent care to minimize pilling |

| Cost | Typically higher due to specialized finishing | Lower cost; standard finishing process |

| Application | Used in high-quality apparel and performance wear | Common in basic or budget textile products |

Overview of Anti-Pilling Finish vs Non Anti-Pilling Finish

Anti-pilling finish is a textile treatment designed to prevent the formation of small fiber balls, or pills, on fabric surfaces, enhancing durability and maintaining a smoother appearance over time. Non anti-pilling finish fabrics lack this protective treatment, making them more susceptible to pilling caused by friction during wear and washing. The choice between anti-pilling and non anti-pilling finishes significantly impacts fabric longevity, texture, and overall garment quality.

Understanding Fabric Pilling

Fabric pilling occurs when fibers break and tangle on the surface, creating small, unsightly balls that degrade the garment's appearance and texture. An anti-pilling finish is applied to fabrics to reduce fiber abrasion and prevent pill formation, extending the lifespan and maintaining the smoothness of your clothing. Non anti-pilling finishes lack this treatment, making fabrics more susceptible to pilling and requiring more frequent maintenance or replacement.

What Is an Anti-Pilling Finish?

An anti-pilling finish is a textile treatment designed to prevent the formation of small, unsightly fabric balls called pills, enhancing the garment's durability and appearance. This finish works by strengthening fiber bonds and reducing friction, ensuring your clothing maintains a smooth and new look even after repeated wear and washing. In contrast, non anti-pilling finishes lack these protective properties, resulting in quicker fabric degradation and noticeable pilling over time.

How Non Anti-Pilling Finish Affects Fabric Longevity

Non anti-pilling finish fabrics tend to develop small fiber balls or pills on the surface over time, which weakens the fabric's structure and reduces its lifespan. Without an anti-pilling finish, fibers break and entangle more easily during washing or friction, accelerating wear and tear. Your fabric's longevity significantly decreases without this protective treatment, making maintenance and durability more challenging.

Key Differences Between Anti-Pilling and Non Anti-Pilling Finishes

Anti-pilling finishes create a protective layer on fabric surfaces, preventing the formation of small fiber balls called pills, thus enhancing garment durability and appearance. Non anti-pilling finishes lack this treatment, resulting in more frequent fuzz and pilling over time, especially after repeated washing and abrasion. Your choice between these finishes influences fabric longevity, maintenance, and overall aesthetic quality.

Pros and Cons of Anti-Pilling Finish

Anti-pilling finish significantly enhances fabric durability by preventing the formation of unsightly pills, maintaining a smooth and new appearance for longer periods. This finish may reduce fabric softness and breathability, potentially causing stiffness or discomfort in certain garments. Your choice depends on balancing fabric longevity with desired texture and comfort levels in everyday wear.

Pros and Cons of Non Anti-Pilling Finish

Non anti-pilling finish fabrics offer a softer and more breathable texture, enhancing comfort in wearable items. However, these fabrics are prone to forming small, unsightly pills with wear and washing, reducing their aesthetic appeal and longevity. The absence of anti-pilling treatment often results in higher maintenance demands and shorter fabric lifespan compared to anti-pilling finish textiles.

Best Applications for Anti-Pilling and Non Anti-Pilling Fabrics

Anti-pilling finish is ideal for high-wear garments such as activewear, outerwear, and upholstery where fabric longevity and a smooth appearance are essential. Non anti-pilling fabrics are better suited for low-friction uses like delicate scarves, formal wear, and decorative textiles where softness and natural texture are prioritized over durability. Choosing the right finish depends on balancing fabric performance requirements with aesthetic preferences in specific applications.

How to Identify Anti-Pilling Finished Fabrics

Anti-pilling finished fabrics can be identified by their smooth surface and resistance to small fiber balls or fuzz that typically form after repeated wear or washing. You can also perform a simple rub test, where fabrics treated with an anti-pilling finish show minimal fiber breakage compared to non anti-pilling fabrics, which quickly develop pills. Look for product labels or descriptions specifying anti-pilling technology, as this chemical treatment creates a stronger fiber bond, maintaining the fabric's appearance and durability over time.

Care and Maintenance Tips for Both Finishes

Anti-pilling finishes require gentle washing with mild detergents and avoiding high heat to maintain fabric integrity and prolong the smooth surface. Non-anti-pilling fabrics should be washed separately to reduce friction and prevent pill formation, with air drying preferred over machine drying to minimize abrasion. Both finishes benefit from turning garments inside out during washing and using fabric softeners to reduce static and fiber damage.

Anti-Pilling Finish vs Non Anti-Pilling Finish Infographic

libmatt.com

libmatt.com