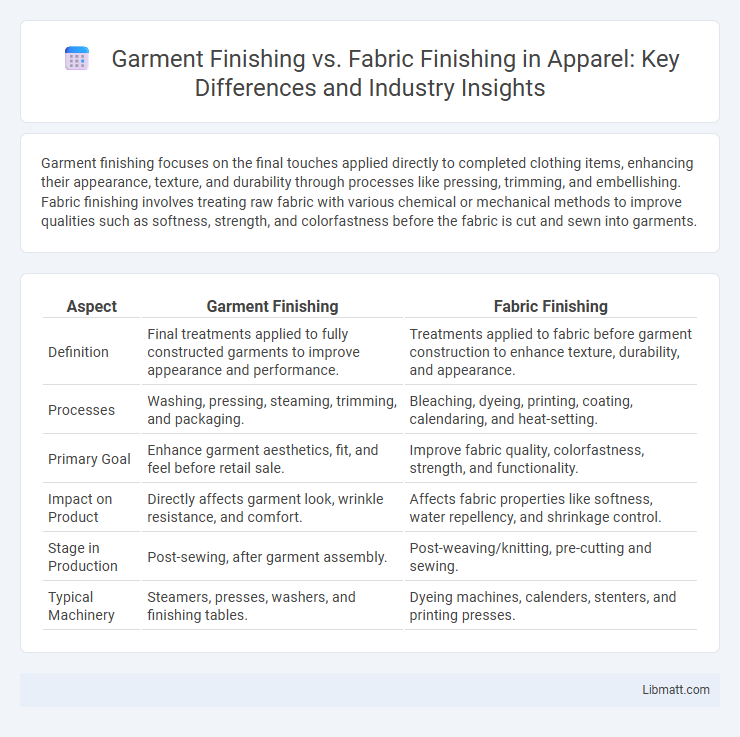

Garment finishing focuses on the final touches applied directly to completed clothing items, enhancing their appearance, texture, and durability through processes like pressing, trimming, and embellishing. Fabric finishing involves treating raw fabric with various chemical or mechanical methods to improve qualities such as softness, strength, and colorfastness before the fabric is cut and sewn into garments.

Table of Comparison

| Aspect | Garment Finishing | Fabric Finishing |

|---|---|---|

| Definition | Final treatments applied to fully constructed garments to improve appearance and performance. | Treatments applied to fabric before garment construction to enhance texture, durability, and appearance. |

| Processes | Washing, pressing, steaming, trimming, and packaging. | Bleaching, dyeing, printing, coating, calendaring, and heat-setting. |

| Primary Goal | Enhance garment aesthetics, fit, and feel before retail sale. | Improve fabric quality, colorfastness, strength, and functionality. |

| Impact on Product | Directly affects garment look, wrinkle resistance, and comfort. | Affects fabric properties like softness, water repellency, and shrinkage control. |

| Stage in Production | Post-sewing, after garment assembly. | Post-weaving/knitting, pre-cutting and sewing. |

| Typical Machinery | Steamers, presses, washers, and finishing tables. | Dyeing machines, calenders, stenters, and printing presses. |

Introduction to Garment and Fabric Finishing

Garment finishing involves processes applied to completed clothing items to enhance appearance, texture, and durability, including washing, pressing, and adding embellishments. Fabric finishing, on the other hand, refers to treatments given to raw textile materials before garment construction, such as dyeing, coating, or applying chemical finishes for improved softness, water resistance, or wrinkle control. Understanding both fabric and garment finishing techniques is essential for optimizing your product's quality and performance.

Definition of Garment Finishing

Garment finishing refers to the final processing steps applied to a fully constructed garment to enhance its appearance, texture, and durability, including processes such as pressing, steaming, trimming, and quality inspection. This stage ensures the garment meets specific aesthetic and functional standards before reaching consumers. It differs from fabric finishing, which involves treating raw fabric to improve qualities like softness, colorfastness, and strength before garment assembly.

Definition of Fabric Finishing

Fabric finishing refers to the series of mechanical and chemical processes applied to raw fabrics to enhance their appearance, texture, durability, and performance characteristics before garment manufacturing. It includes treatments such as bleaching, dyeing, printing, waterproofing, and softening that transform the fabric's surface and improve qualities like colorfastness, shrink resistance, and hand feel. Unlike garment finishing, which focuses on completed clothing items, fabric finishing targets the textile material itself to prepare it for subsequent production stages.

Key Differences Between Garment and Fabric Finishing

Garment finishing involves processes applied to fully constructed clothing to enhance aesthetics, fit, and durability, such as pressing, trimming, and surface treatments. Fabric finishing refers to treatments performed on raw textile materials before garment assembly, including dyeing, printing, and mechanical or chemical modifications to improve texture and performance. The key difference lies in the timing and focus: fabric finishing optimizes the textile's properties, while garment finishing finalizes the product's appearance and function.

Common Methods in Garment Finishing

Common methods in garment finishing include pressing, steaming, and heat-setting, which enhance the garment's shape and appearance while ensuring durability. Garment finishing also involves trimming, button attaching, and label sewing to prepare the piece for retail. Your clothing benefits from these precise techniques, resulting in a polished and market-ready final product.

Popular Techniques in Fabric Finishing

Popular techniques in fabric finishing enhance the texture, appearance, and durability of textiles through processes such as calendaring, mercerizing, and sanforizing. Calendaring uses high-pressure rollers to produce a smooth, glossy surface, while mercerizing treats cotton with caustic soda to increase luster and dye affinity. Sanforizing minimizes fabric shrinkage, ensuring your garments maintain shape and fit after washing.

Advantages of Garment Finishing

Garment finishing enhances the final product by allowing precise customization of individual items, resulting in superior fit, appearance, and quality compared to fabric finishing. It reduces defects through targeted inspections and corrections, improving overall garment consistency and customer satisfaction. This process also enables efficient handling of small production runs and design variations, supporting flexible manufacturing demands.

Benefits of Fabric Finishing

Fabric finishing enhances textile durability, softness, and appearance by applying treatments such as calendaring, heat-setting, and chemical coatings that improve texture and functionality. It increases resistance to shrinking, wrinkling, and stains, resulting in higher-quality materials ideal for various applications. Improved fabric breathability and moisture-wicking properties contribute to comfort and performance in final garments.

Impact on Final Garment Quality

Garment finishing directly influences the final garment quality by enhancing fit, texture, and appearance through processes like stitching, pressing, and trimming. Fabric finishing affects fabric durability, hand feel, and colorfastness by applying treatments such as dyeing, coating, and softening before garment construction. Your choice of fabric finishing sets the foundation for garment finishing quality, collectively determining the wearability and aesthetic appeal of the end product.

Choosing the Right Finishing Process

Choosing the right finishing process depends on the end use and desired properties of the textile product. Garment finishing enhances the appearance, fit, and feel of the final clothing item through techniques like pressing, washing, and trimming. Fabric finishing, such as calendaring, coating, or dyeing, improves fabric performance by adding durability, softness, or water resistance before garment construction.

Garment Finishing vs Fabric Finishing Infographic

libmatt.com

libmatt.com