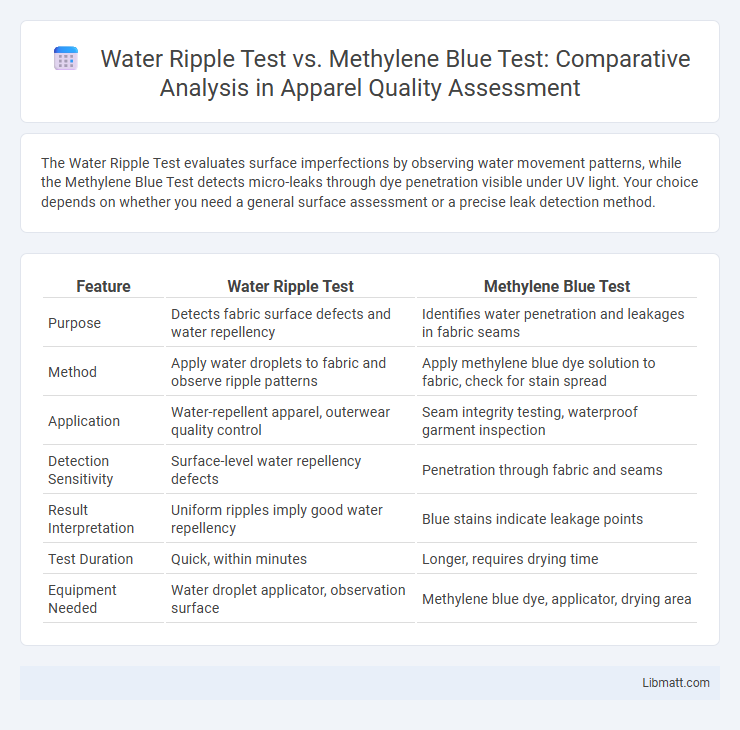

The Water Ripple Test evaluates surface imperfections by observing water movement patterns, while the Methylene Blue Test detects micro-leaks through dye penetration visible under UV light. Your choice depends on whether you need a general surface assessment or a precise leak detection method.

Table of Comparison

| Feature | Water Ripple Test | Methylene Blue Test |

|---|---|---|

| Purpose | Detects fabric surface defects and water repellency | Identifies water penetration and leakages in fabric seams |

| Method | Apply water droplets to fabric and observe ripple patterns | Apply methylene blue dye solution to fabric, check for stain spread |

| Application | Water-repellent apparel, outerwear quality control | Seam integrity testing, waterproof garment inspection |

| Detection Sensitivity | Surface-level water repellency defects | Penetration through fabric and seams |

| Result Interpretation | Uniform ripples imply good water repellency | Blue stains indicate leakage points |

| Test Duration | Quick, within minutes | Longer, requires drying time |

| Equipment Needed | Water droplet applicator, observation surface | Methylene blue dye, applicator, drying area |

Introduction to Water Ripple Test and Methylene Blue Test

Water Ripple Test detects microcracks and porosity in materials by observing surface ripple patterns created when water spreads across a surface, making it effective for identifying surface irregularities without damaging the object. Methylene Blue Test involves applying a blue dye solution to a sample, where it penetrates and highlights cracks and pores by staining them, offering a vivid visual confirmation of defects and porosity. Both tests serve as non-destructive evaluation methods commonly used in industries like construction and manufacturing to assess material integrity and quality.

Overview of Water Ripple Test: Principles and Applications

The Water Ripple Test detects surface cracks and porosity by observing wave patterns formed on water when applied to a component, making it ideal for inspecting welds and castings. Principles involve surface tension and wave interference to reveal discontinuities that are otherwise invisible to the naked eye. Your inspection process benefits from this non-destructive method's immediate and visual defect identification without requiring specialized chemical reagents.

Understanding the Methylene Blue Test: Mechanism and Uses

The Methylene Blue Test detects microleakages by staining compromised areas through the diffusion of methylene blue dye, which highlights defects in dental restorations or porous materials. This method relies on the dye's low molecular weight and high affinity for water, allowing it to penetrate tiny gaps undetectable by visual inspection or other tests like the Water Ripple Test. Widely used in dentistry and material science, the Methylene Blue Test provides precise identification of microleakage sites, ensuring the assessment of seal integrity and material durability.

Key Differences Between Water Ripple and Methylene Blue Tests

Water Ripple Test evaluates fluid flow and leak detection by observing ripple patterns on water surfaces, primarily used in pipeline and tank inspections for surface leaks. Methylene Blue Test employs a dye tracer to identify leaks or fluid contamination, widely applied in medical diagnostics and packaging seal integrity assessments. The key differences lie in detection mechanisms--visual surface disturbance versus colorimetric dye tracing--and applicable industries, with Water Ripple Test suited for large-scale fluid systems and Methylene Blue Test ideal for precise leak localization in small or sealed environments.

Advantages of Water Ripple Test in Material Analysis

The Water Ripple Test offers the advantage of non-destructive evaluation in material analysis, allowing for surface defect detection without damaging the specimen. This method provides rapid visualization of surface imperfections such as cracks and delaminations through ripple pattern distortions, enhancing inspection efficiency. Compared to the Methylene Blue Test, it eliminates chemical handling risks and reduces environmental impact, making it a safer and more sustainable choice for quality control.

Benefits of Methylene Blue Test in Laboratory Settings

The Methylene Blue Test offers enhanced sensitivity and accuracy in detecting microbial contamination compared to the Water Ripple Test, making it invaluable in laboratory settings. This test provides rapid and reliable results with minimal sample preparation, ensuring efficient workflow and quality control. By using the Methylene Blue Test, Your laboratory can achieve precise microbial assessment crucial for maintaining product safety and compliance.

Suitability for Different Materials: Which Test to Choose?

The Water Ripple Test is ideal for non-porous surfaces such as glass and polished metals, providing quick detection of surface defects through visual distortion analysis. In contrast, the Methylene Blue Test excels in identifying cracks and permeability in porous materials like ceramics and concrete due to its dye penetration properties. Selecting between these tests depends on the material's porosity and the nature of defects being investigated, with Water Ripple favored for surface imperfections and Methylene Blue optimal for subsurface flaw detection.

Accuracy and Reliability: Water Ripple Test vs Methylene Blue Test

The Water Ripple Test demonstrates high reliability in detecting surface defects by visually identifying water flow disruptions, making it more sensitive to minor leaks and inconsistencies. In contrast, the Methylene Blue Test offers superior accuracy for pinpointing micro-leaks through dye penetration, providing a clear, quantifiable indication of breaches in sealed systems. Both tests complement each other--Water Ripple excels in quick, large-area assessments while Methylene Blue delivers detailed, confirmatory results for critical leak detection.

Practical Considerations: Equipment, Cost, and Time Factors

The Water Ripple Test requires minimal equipment, primarily a clean water surface and a light source, making it a cost-effective and quick option for preliminary inspections. In contrast, the Methylene Blue Test involves chemical reagents, specialized containers, and safety precautions, resulting in higher material costs and longer handling times. Your choice depends on balancing the need for speed and simplicity against the accuracy and detail provided by the more resource-intensive Methylene Blue Test.

Conclusion: Choosing the Right Test for Your Application

Selecting between the Water Ripple Test and the Methylene Blue Test depends on the specific application requirements and sensitivity needs. The Water Ripple Test is ideal for detecting surface irregularities and evaluating water resistance in coatings, while the Methylene Blue Test excels in identifying porosity and leakage in materials due to its high sensitivity to microscopic defects. For precise leak detection and material integrity assessment, the Methylene Blue Test offers superior accuracy, whereas the Water Ripple Test suits quick, non-destructive surface inspections.

Water Ripple Test vs Methylene Blue Test Infographic

libmatt.com

libmatt.com