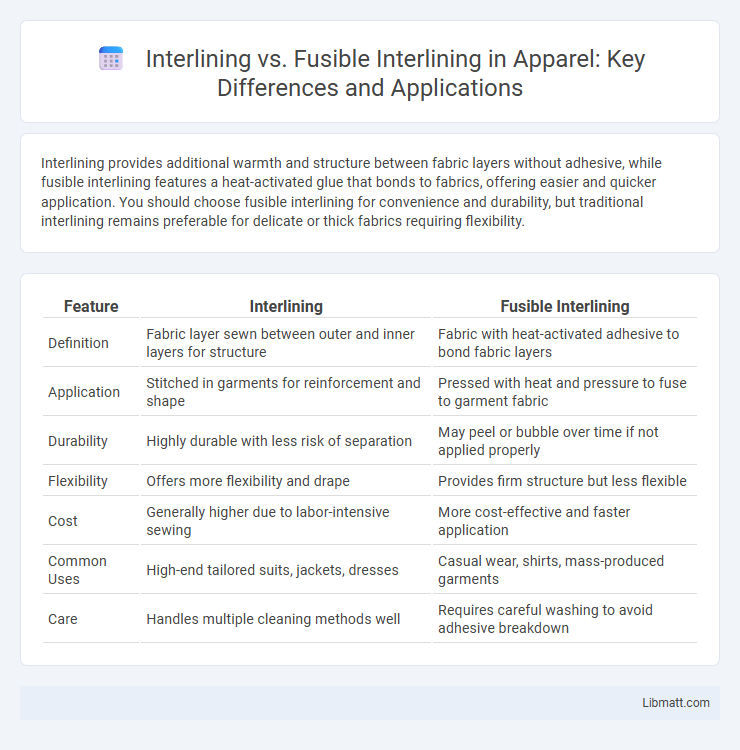

Interlining provides additional warmth and structure between fabric layers without adhesive, while fusible interlining features a heat-activated glue that bonds to fabrics, offering easier and quicker application. You should choose fusible interlining for convenience and durability, but traditional interlining remains preferable for delicate or thick fabrics requiring flexibility.

Table of Comparison

| Feature | Interlining | Fusible Interlining |

|---|---|---|

| Definition | Fabric layer sewn between outer and inner layers for structure | Fabric with heat-activated adhesive to bond fabric layers |

| Application | Stitched in garments for reinforcement and shape | Pressed with heat and pressure to fuse to garment fabric |

| Durability | Highly durable with less risk of separation | May peel or bubble over time if not applied properly |

| Flexibility | Offers more flexibility and drape | Provides firm structure but less flexible |

| Cost | Generally higher due to labor-intensive sewing | More cost-effective and faster application |

| Common Uses | High-end tailored suits, jackets, dresses | Casual wear, shirts, mass-produced garments |

| Care | Handles multiple cleaning methods well | Requires careful washing to avoid adhesive breakdown |

Introduction to Interlining and Fusible Interlining

Interlining provides structural support and shape to garments, enhancing durability and comfort, while fusible interlining features a heat-activated adhesive that bonds directly to fabric for a clean, wrinkle-free finish. You can choose fusible interlining for quicker application and tailored precision, or traditional interlining for layered flexibility and breathability. Both interlining types are essential in tailoring, influencing garment quality and performance in various textile applications.

What is Interlining?

Interlining is a fabric layer placed between the outer fabric and lining to provide structure, support, and insulation in garments. Unlike fusible interlining, which uses heat-activated adhesive to bond with the fabric, traditional interlining is sewn or basted in, offering flexibility in tailoring and fabric choice. Understanding the differences in interlining types helps enhance your clothing's durability, shape retention, and comfort.

Understanding Fusible Interlining

Fusible interlining consists of a layer of fabric coated with a heat-activated adhesive that bonds to your garment fabric when pressed, enhancing structure and durability without stitching. Unlike traditional interlining, fusible interlining simplifies garment construction by eliminating the need for sewing the interfacing separately, making it ideal for mass production. Understanding fusible interlining helps you choose the right support for your fabric type and desired garment finish, ensuring professional results and improved wearability.

Key Differences Between Interlining and Fusible Interlining

Interlining and fusible interlining differ primarily in their application and composition; traditional interlining is a separate layer sewn between fabric layers to provide structure, while fusible interlining features a heat-activated adhesive that bonds directly to the fabric. Fusible interlining offers greater convenience and time efficiency in garment construction, enhancing durability and shape retention without additional stitching. Your choice between these materials impacts garment quality, production speed, and desired fabric flexibility.

Types of Interlining Materials

Interlining materials are essential for adding structure and support to garments, with two main types: interlining and fusible interlining. Interlining typically uses non-adhesive fibers like cotton, wool, or synthetic blends that require sewing or manual attachment, providing flexibility and softness. Fusible interlining incorporates a heat-activated adhesive layer, often made from polyester or nylon, which bonds to the fabric when pressed, offering convenience and enhanced stability for Your sewing projects.

Advantages of Traditional Interlining

Traditional interlining offers superior breathability and comfort due to its natural fiber composition, making it ideal for garments worn long hours. Its durability allows for repeated pressing and reshaping without losing structure, ensuring your clothing retains a crisp, professional appearance. Furthermore, traditional interlining provides excellent support and shape retention, enhancing the overall fit and drape of tailored garments.

Benefits of Fusible Interlining

Fusible interlining provides enhanced garment structure and shape retention by bonding directly to fabric with heat-activated adhesive, eliminating the need for sewing. This method offers time-saving benefits during production and results in a smoother, more professional finish with reduced fabric distortion. You can achieve increased durability and improved wrinkle resistance, making fusible interlining a preferred choice for high-quality apparel manufacturing.

Applications in Garment Construction

Interlining plays a crucial role in garment construction by providing structure and support, with fusible interlining offering added convenience through adhesive bonding that eliminates the need for stitching. Fusible interlining is ideal for lightweight fabrics in tailored garments, ensuring durability and shape retention without bulk. Your choice between interlining types impacts garment durability, comfort, and overall finish, particularly in collars, cuffs, and waistbands.

Choosing the Right Interlining for Your Project

Selecting the right interlining for your project depends on fabric type, desired garment structure, and application method. Fusible interlining bonds through heat and is ideal for lightweight fabrics requiring precise shaping, while traditional interlining offers flexibility and is better suited for heavy fabrics or tailored garments needing softer support. Understanding the fabric characteristics and end-use ensures optimal performance and durability in the final product.

Conclusion: Interlining vs Fusible Interlining

Interlining provides superior breathability and flexibility, making it ideal for high-quality, tailored garments requiring a natural drape. Fusible interlining offers convenience and faster production with a heat-activated adhesive backing, perfect for mass manufacturing and maintaining garment shape. Choosing between interlining and fusible interlining depends on balancing the desired garment performance, production efficiency, and end-user comfort.

Interlining vs Fusible Interlining Infographic

libmatt.com

libmatt.com